Preparation method of high-stretch lignin-based carbon fiber

A plain-based carbon fiber and lignin-based technology is applied in the field of preparation of high-stretch lignin-based carbon fiber, which can solve the problems of high preparation cost, long pre-oxidation time, low carbonization yield, etc. The effect of less oxidation time and low cost of incoming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

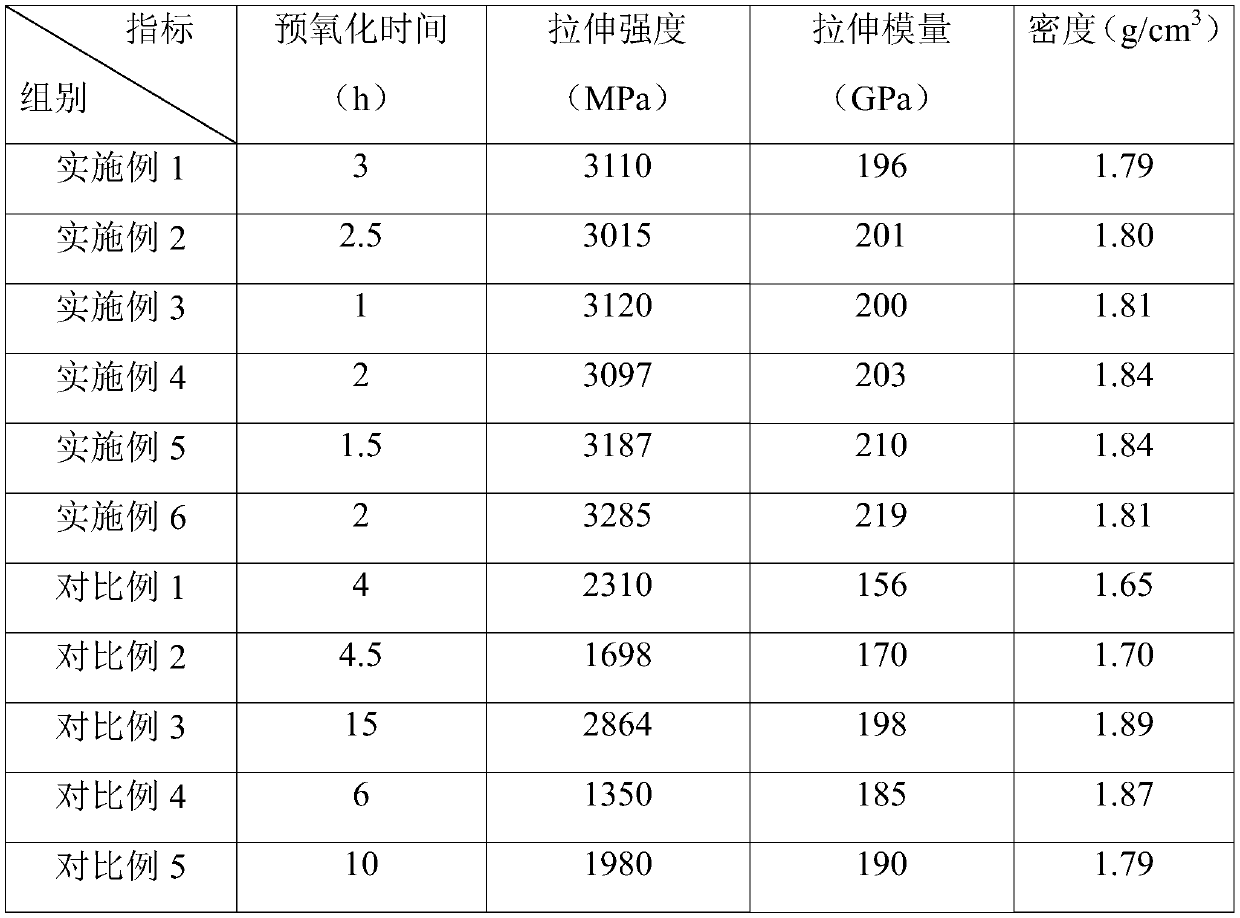

Examples

Embodiment 1

[0038] A method for preparing high-stretch lignin-based carbon fibers comprises the following steps;

[0039] (1) Recovery of by-products in the cellulose production and purification process;

[0040] (2) Add 2% of the lignin mass percentage to the by-products in a ratio of 1:0.1:0.1 phenol oxidase, yeast and bacillus to carry out fermentation treatment for 1d, and centrifuge the fermentation broth at a speed of 5000r / min. For 5min, after filtering, take the solid part as fermented lignin;

[0041] (3) Add acetic anhydride accounting for 0.3% of the lignin mass percentage and a concentration of 0.5g / mL in the fermented lignin, add a mixture of dioxane and methanol according to the liquid-solid ratio of 3:1, centrifuge, and filter to obtain After purifying the lignin, add 1% potassium chlorate for oxidation treatment at a temperature of 158°C;

[0042] (4) Add 0.1% ferulic acid to the oxidized lignin, blend 0.1% polyethylene, chopped fiber and binder fiber at a ratio of 1:1:1...

Embodiment 2

[0047] A method for preparing high-stretch lignin-based carbon fibers comprises the following steps;

[0048] (1) Recovery of by-products in the cellulose production and purification process;

[0049](2) Add 10% of the lignin mass percentage to the by-products in a ratio of 3:0.2:0.5 glucose oxidase, yeast and bacillus to carry out fermentation treatment for 3 days, and centrifuge the fermentation broth at a speed of 8000r / min. For 15min, after filtering, take the solid part as fermented lignin;

[0050] (3) Add 0.5% of the lignin mass percentage to the fermented lignin, and the concentration is 0.5g / mL of acetic anhydride, add a mixture of dioxane and methanol according to the liquid-solid ratio of 5:1, centrifuge, and filter to obtain After purifying the lignin, add 4% sodium chlorate for oxidation treatment at a temperature of 250°C;

[0051] (4) Add 0.5% ferulic acid to the oxidized lignin, blend 0.3% polyethylene, chopped fiber and binder fiber at a ratio of 3:2:3, and ...

Embodiment 3

[0056] A method for preparing high-stretch lignin-based carbon fibers comprises the following steps;

[0057] (1) Recovery of by-products in the cellulose production and purification process;

[0058] (2) Adding 6% of the lignin mass percentage to the by-products is 2:0.12:0.3 manganese peroxidase, saccharomyces and bacillus to carry out fermentation treatment for 2 days, centrifuge the fermentation broth, the speed of centrifugation is 7000r / min, centrifuge The time is 10 minutes, and the solid part is taken as fermented lignin after filtration;

[0059] (3) Add 0.4% of the lignin mass percentage to the fermented lignin, and the concentration is 0.5g / mL acetic anhydride, according to the liquid-solid ratio, add the mixture of dioxane and methanol of 4:1, centrifuge and filter to obtain After purifying the lignin, add 3% magnesium chlorate for oxidation treatment at a temperature of 200°C;

[0060] (4) Add 0.3% ferulic acid to the oxidized lignin, blend 0.2% polyethylene, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com