A method for interior decoration of roof slabs

A technology for roofing and interior decoration, applied in covering/lining, construction, filling slurry, etc., can solve problems such as poor anti-cracking effect of putty layer, easy cracks in interior walls, hidden safety hazards of putty layer, etc., to improve physical and chemical properties , Improve anti-cracking performance, enhance the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

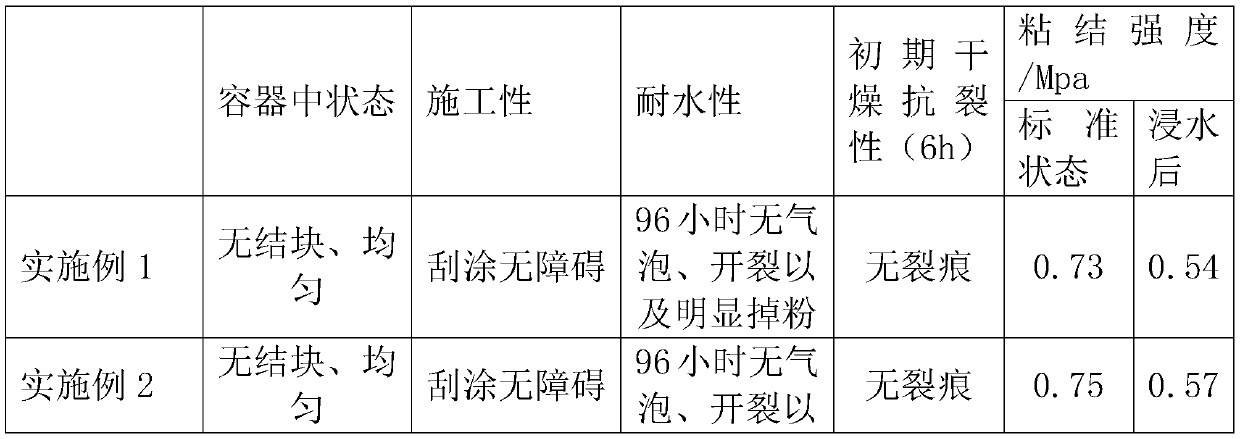

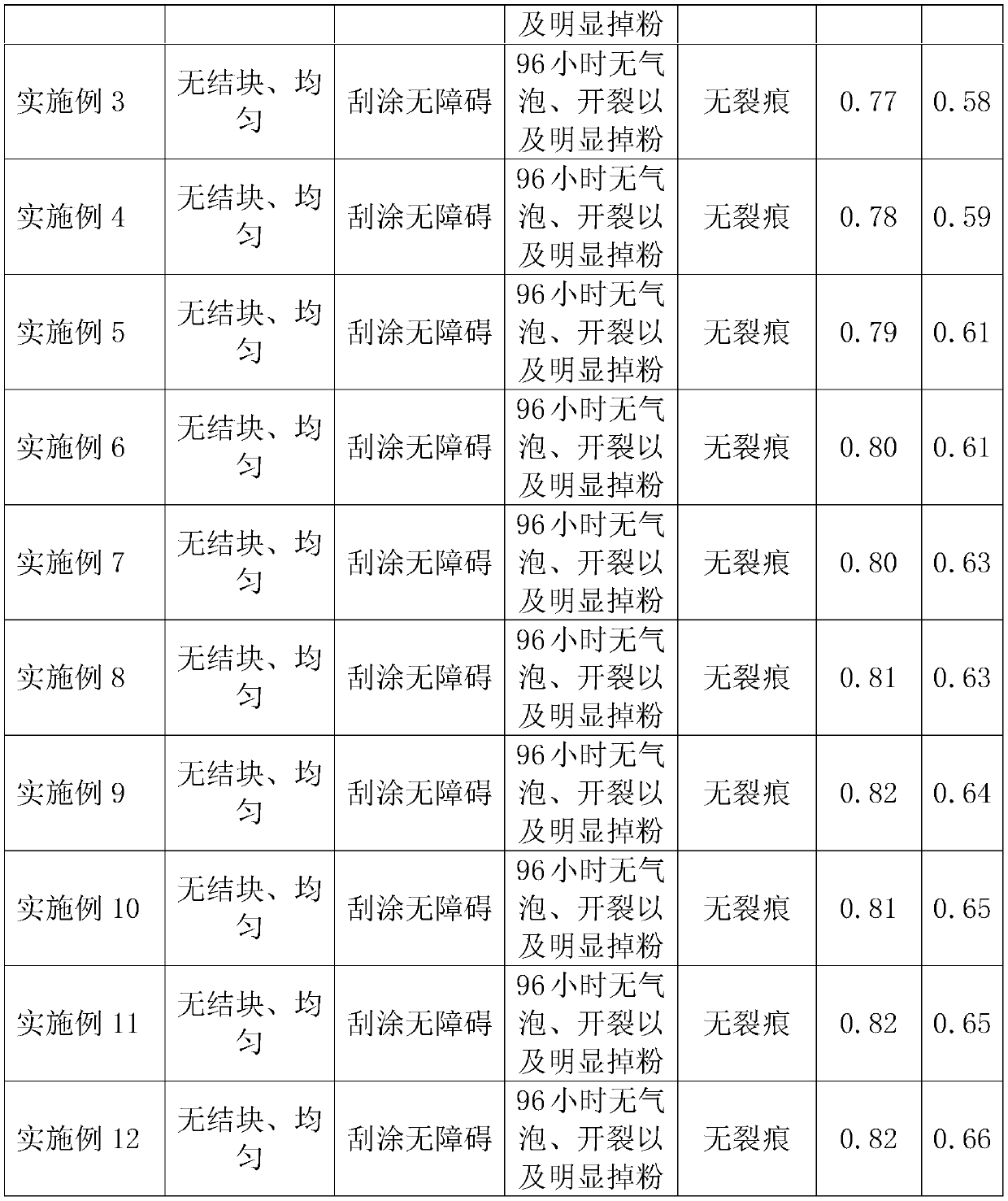

Examples

Embodiment 1

[0065] A method for interior decoration of a house roof, comprising the following steps:

[0066] S1. Wall surface treatment: first clean up the dust, oil and ash on the wall surface, fill and compact the uneven parts of the wall surface with gypsum, and after drying, use sandpaper to remove residues and stains, etc. Impurities are smoothed and polished.

[0067] S2. Apply clear water on the wall to moisten the wall, and then evenly paint the interface agent on the wall.

[0068] S3. After the interface agent on the wall is dry, spray glue evenly on the wall.

[0069] S4. Preparation of putty: After mixing the putty powder and water, stir for 5-7 minutes, let stand for 10-15 minutes, and then stir evenly for 2-5 minutes until the putty is evenly mixed.

[0070] S5. Batch putty scraping. The first batch of putty scraping needs to be scraped horizontally. One scraper is followed by another scraper. There should be no gaps at the joints. After the first putty is dry, sand the p...

Embodiment 2

[0090] The difference with embodiment 1 is:

[0091] In step S5, the thickness of each batch of putty scraping is 1.1 mm.

[0092] The putty of step S4 comprises the following components expressed in parts by weight:

[0093] Talc powder: 75 parts; water: 275 parts; lime powder: 35 parts; acrylic acid emulsion: 15 parts; ethanol: 17.5 parts; phenolic resin: 5 parts; rosin oil: 7.5 parts; lotus root powder: 4 parts; 4 parts; medical stone powder: 3.5 parts; sodium bentonite: 2 parts; defoamer: 1.25 parts; aloe fiber powder: 9 parts.

[0094] In this embodiment, the defoaming agent is a modified silicone defoaming agent of model AS-01 produced by Foshan Nanhai Datian Chemical Co., Ltd.

[0095] In this embodiment, the mesh number of the talcum powder is 325 mesh.

[0096] In this embodiment, the aloe fiber powder is a commercially available aloe fiber powder.

[0097] In this embodiment, the phenolic resin in step S4 is cashew nut shell oil modified phenolic resin.

[0098]...

Embodiment 3

[0106] The difference with embodiment 1 is:

[0107] In step S5, the thickness of each batch of putty scraping is 1.5mm.

[0108] The putty of step S4 comprises the following components expressed in parts by weight:

[0109] Talc powder: 100 parts; water: 300 parts; lime powder: 50 parts; acrylic emulsion: 20 parts; ethanol: 20 parts; phenolic resin: 8 parts; rosin oil: 10 parts; lotus root starch: 6 parts; silane coupling agent: 6 parts; medical stone powder: 5 parts; sodium bentonite: 3 parts; defoamer: 2 parts; aloe fiber powder: 12 parts.

[0110] In this embodiment, the aloe fiber powder is a commercially available aloe fiber powder.

[0111] In this embodiment, the phenolic resin in step S4 is cashew nut shell oil modified phenolic resin.

[0112] In this embodiment, the defoaming agent is a modified silicone defoaming agent of model AS-01 produced by Foshan Nanhai Datian Chemical Co., Ltd.

[0113] In this embodiment, the mesh number of the talcum powder is 500 mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com