Flame-retardant high-molecular material and preparation method thereof

A polymer material and flame retardant technology, applied in the field of flame retardant polymer materials and their preparation, can solve problems such as poor high temperature resistance, and achieve the effects of improving flame retardant performance, strengthening performance and enhancing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

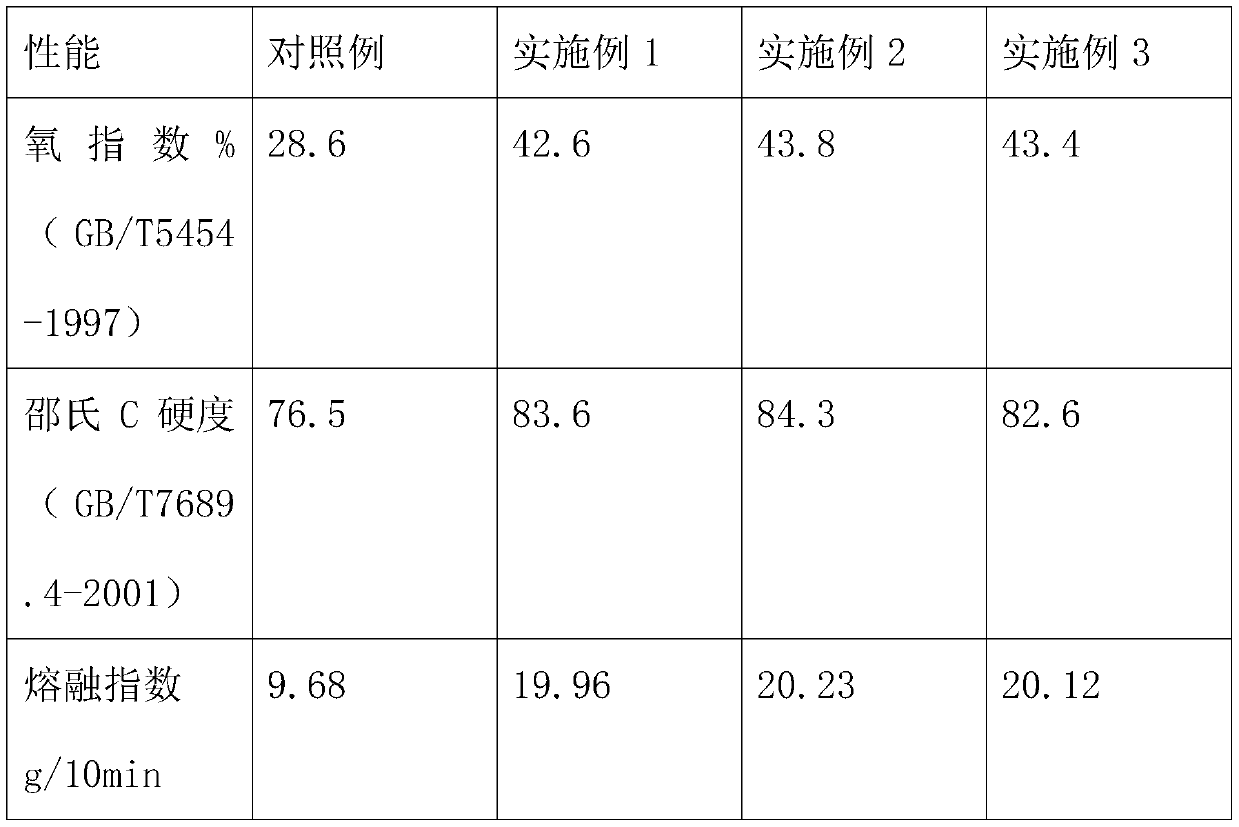

Examples

Embodiment 1

[0019] A flame-retardant polymer material, which is composed of the following raw materials in parts by weight: 15 parts of polyvinyl chloride, 10 parts of nano-calcium silicate hydrate, 11 parts of calcium sulfate, 5 parts of butylphenylpyrrolate latex, and 3 parts of polyvinylidene chloride 2 parts, 2 parts of antimony trioxide, 2 parts of hydrated alumina, 2 parts of zinc borate, 2 parts of magnesium hydroxide, 3 parts of polybenzimidazole fiber, 1 part of DOPO derivative flame retardant, 3 parts of modified inorganic filler, 0.5 part of polyethylene terephthalate, 0.5 part of polyamide resin, 0.3 part of phthalate, 1 part of defoamer.

[0020] A method for preparing a flame-retardant polymer material, comprising the steps of:

[0021] 1) Polyvinyl chloride, nano-calcium silicate hydrate, calcium sulfate, styrene-butadiene latex, polyvinylidene chloride, antimony trioxide, hydrated alumina, zinc borate, magnesium hydroxide, polybenzimidazole fiber, DOPO derivative flame re...

Embodiment 2

[0026] A flame-retardant polymer material, which is composed of the following raw materials in parts by weight: 20 parts of polyvinyl chloride, 12 parts of nano-calcium silicate hydrate, 13 parts of calcium sulfate, 8 parts of butylbenzenepyridine latex, and 5 parts of polyvinylidene chloride 5 parts, antimony trioxide 5 parts, hydrated alumina 5 parts, zinc borate 5 parts, magnesium hydroxide 5 parts, polybenzimidazole fiber 5 parts, DOPO derivative flame retardant 3 parts, modified inorganic filler 5 parts, 0.8 parts of polyethylene terephthalate, 0.9 parts of polyamide resin, 0.5 parts of phthalate, 2 parts of defoamer.

[0027] A method for preparing a flame-retardant polymer material, comprising the steps of:

[0028] 1) Polyvinyl chloride, nano-calcium silicate hydrate, calcium sulfate, styrene-butadiene latex, polyvinylidene chloride, antimony trioxide, hydrated alumina, zinc borate, magnesium hydroxide, polybenzimidazole fiber, DOPO derivative flame retardant, modifie...

Embodiment 3

[0033] A flame-retardant polymer material, which is composed of the following raw materials in parts by weight: 18 parts of polyvinyl chloride, 11 parts of nano-calcium silicate hydrate, 12 parts of calcium sulfate, 6 parts of butylbenzenepyridine latex, and 4 parts of polyvinylidene chloride 4 parts, antimony trioxide 4 parts, hydrated alumina 4 parts, zinc borate 4 parts, magnesium hydroxide 4 parts, polybenzimidazole fiber 4 parts, DOPO derivative flame retardant 2 parts, modified inorganic filler 4 parts, 0.6 parts of polyethylene terephthalate, 0.7 parts of polyamide resin, 0.4 parts of phthalate, and 1.5 parts of defoamer.

[0034] A method for preparing a flame-retardant polymer material, comprising the steps of:

[0035] 1) Polyvinyl chloride, nano-calcium silicate hydrate, calcium sulfate, styrene-butadiene latex, polyvinylidene chloride, antimony trioxide, hydrated alumina, zinc borate, magnesium hydroxide, polybenzimidazole fiber, DOPO derivative flame retardant, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com