Method for preparing cellulose nanocrystal gel bionic skin sensing material with electric-conducting and self-healing functions

A sensing material, cellulose technology, applied in the field of preparation of cellulose nanocrystal mixed hydrogel, can solve the problems of large brittleness, and achieve a large surface area, stable electrical conductivity, mild healing conditions, excellent electrical conductivity and self-healing properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

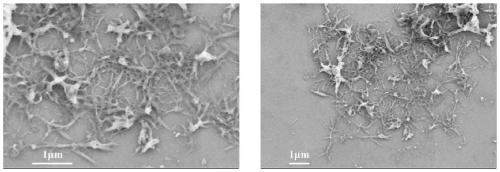

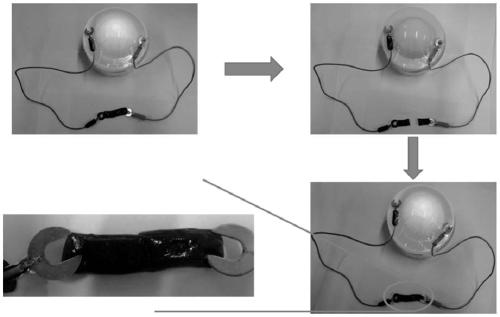

[0030] Add 5.2g of pyrrole to 2g of CNC aqueous suspension (1wt%) and mix evenly, then add 50ml of HCl (1mol / L), stir magnetically in -1°C water for 1h, and dissolve 3.6g of FeCl 3 The aqueous solution was added to the CNC mixed suspension, placed in -1°C water and magnetically stirred for 2 hours, and the obtained product was washed to neutrality, and 0.8g of borax (Na 2 B 4 o 7 10H 2 O) Dissolve the powder in 20ml of CNC mixed suspension product, stir continuously at room temperature for 20min, slowly add 3.0g of PVA powder into the stirred aqueous solution, after the PVA powder is completely swollen, heat the solution to 95°C and stir for 3h, with As the temperature rises, the PVA powder begins to dissolve, and the mixture gradually becomes viscous. After the PVA is completely dissolved, a well-dispersed CNC mixed solution is formed. As the temperature decreases, the solution begins to exhibit viscoelastic properties. The solution is further slowly cooled to room temperat...

Embodiment 2

[0032] Add 1g of aniline to 0.1g of CNC aqueous suspension (0.1wt%) and mix well, then add 10ml of HMnO 4 (0.1mol / L), followed by magnetic stirring in -5°C water for 2h, 0.1g iron sulfate (Fe 2 (SO 4 ) 3 ) was added to the CNC mixed suspension, placed in -5 ° C water for 4 hours, and the obtained product was washed to neutrality, and 0.01g of titanium boride (TiB 2) powder was dissolved in 10ml of CNC mixed suspension product, stirred continuously at room temperature for 40min, slowly added 0.1g of PVA powder into the stirred aqueous solution, and after the PVA powder was completely swollen, the solution was heated to 70°C and stirred for 5h, with As the temperature rises, the PVA powder begins to dissolve, and the mixture gradually becomes viscous. After the PVA is completely dissolved, a well-dispersed CNC mixed solution is formed. As the temperature decreases, the solution begins to exhibit viscoelastic properties. The solution is further slowly cooled to room temperature...

Embodiment 3

[0034] 10g thiophene was added to 5g CNC aqueous suspension (2wt%) and mixed evenly, then 20ml HClO was added 4 (2mol / L), followed by magnetic stirring in water at 0°C for 3h, adding 5g of sodium chloride (NaCl) into the CNC mixed suspension, placing it in water at 0°C for magnetic stirring for 1h, washing the obtained product with water until neutral, and 3.5g boron oxide (B 2 o 3 ) powder was dissolved in 30ml of CNC mixed suspension product, stirred continuously at room temperature for 30min, 8.0g of PVA powder was slowly added into the stirred aqueous solution, and after the PVA powder was completely swollen, the solution was heated to 100°C and stirred for 7h, with As the temperature rises, the PVA powder begins to dissolve, and the mixture gradually becomes viscous. After the PVA is completely dissolved, a well-dispersed CNC mixed solution is formed. As the temperature decreases, the solution begins to exhibit viscoelastic properties. The solution is further slowly cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com