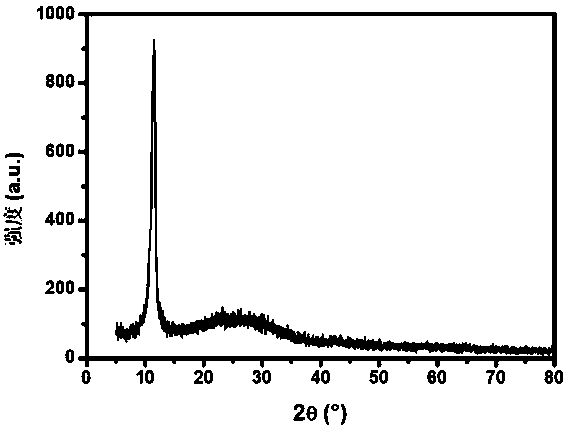

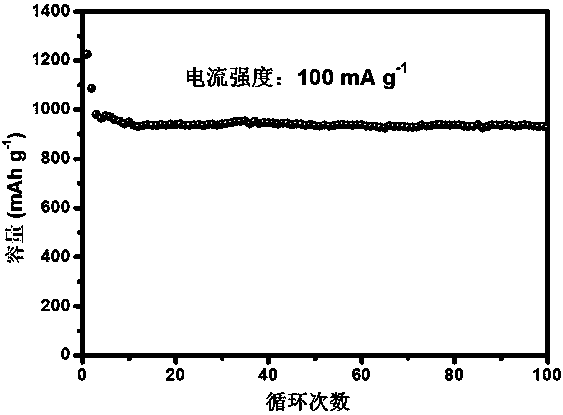

Molybdenum disulfide-three-dimensional graphene composite material

A technology of molybdenum disulfide and composite materials, which is applied in the field of nanocomposite materials and its applications, can solve the problems of electrode damage, unstable graphene bonding, long reaction time, etc. Fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of graphene oxide: slowly add 100mL of 98% concentrated sulfuric acid into a 500mL dry three-necked flask, and place the three-necked flask on a magnetic stirrer for ice bath cooling. Add 2.0 g of natural graphite flakes (180 mesh) under rapid stirring, and when the temperature of the reaction solution drops to about 0° C., slowly add 4.0 g of sodium nitrate, and continue stirring for 2 h. Then slowly add 10 g of potassium permanganate in batches within 1 h, keep stirring for 2 h, and control the reaction temperature below 10°C. Then the three-neck flask was moved into a water bath at 40° C., and the stirring reaction was continued for 2 h. Subsequently, 200 mL of warm deionized water was slowly added, and the temperature of the reaction solution was kept within 100 °C. React at a constant temperature of 98°C until the reaction solution turns bright yellow. Add 20 mL of 30% hydrogen peroxide to the reaction liquid, and keep stirring to make it fully react....

Embodiment 2

[0033] The preparation method of graphene oxide and three-dimensional graphene airgel is the same as embodiment 1

[0034] Preparation of molybdenum disulfide-three-dimensional graphene composites: mix sulfur powder, ammonium paramolybdate and three-dimensional graphene airgel at a mass ratio of 1:1:4, place the mixture in an agate tank filled with nitrogen, and use Ball mill ball milling, the mass ratio of balls to materials is 3:1, the rotation speed is 400rpm, after 1 hour of ball milling, cool naturally to room temperature to collect the product. The ball-milled material was put into a reaction tube, placed in a microwave reaction chamber, and purged with argon gas at 100 mL / min for 1 h. Microwave with 600W power for 10min. Cool to room temperature under an Ar atmosphere to obtain a molybdenum disulfide-three-dimensional graphene composite material.

Embodiment 3

[0036] The preparation method of graphene oxide and three-dimensional graphene airgel is the same as embodiment 1

[0037] Preparation of molybdenum disulfide-three-dimensional graphene composites: mix sulfur powder, ammonium paramolybdate and three-dimensional graphene airgel at a mass ratio of 1:2:4, place the mixture in an agate tank filled with nitrogen, and use Ball mill ball milling, the mass ratio of balls to materials is 3:1, the rotation speed is 400rpm, after 1 hour of ball milling, cool naturally to room temperature to collect the product. The ball-milled material was put into a reaction tube, placed in a microwave reaction chamber, and purged with argon gas at 100 mL / min for 1 h. Microwave with 600W power for 10min. Cool to room temperature under an Ar atmosphere to obtain a molybdenum disulfide-three-dimensional graphene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com