Method for continuously rapidly synthesizing 2-hydroxy-4-methylthio butyronitrile

A technology of methylthiobutyronitrile and methylthiopropionaldehyde, which is applied in the chemical industry, can solve problems such as lack of economy and economy, generation of colored impurities, and easy production of by-products, so as to avoid post-processing procedures, reduce usage, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

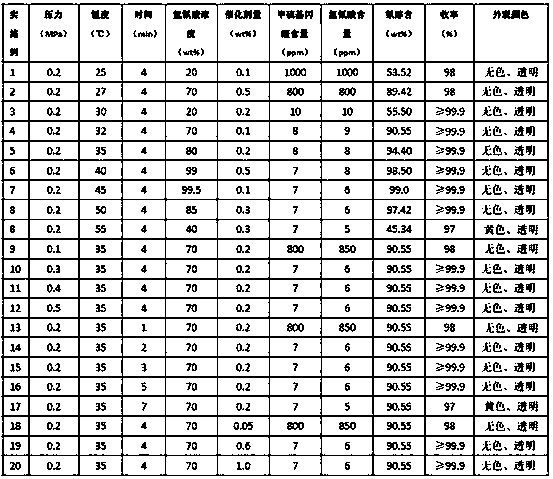

Image

Examples

Embodiment

[0035] Catalyst configuration:

[0036] Add 7030 grams of deionized water to a stirred reactor, then add 2077 grams of 99% citric acid solids and 900 grams of 96% sodium hydroxide solids under stirring, and stir until completely dissolved to obtain lemons Acid-sodium citrate buffer, the mass percentage of citric acid in the buffer is 20.55wt%, sealed and stored at room temperature as a catalyst for the subsequent cyanation reaction, the pH of the lemon-sodium citrate buffer is 5.0.

[0037] Mix 52.612g (0.5mol) of methylthiopropionaldehyde (purity 99wt%) with the catalyst prepared above in a certain proportion (the mass ratio of citric acid and methylthiopropionaldehyde in the catalyst is 0.1wt%~0.5wt %), and then divided into A\B flow with hydrocyanic acid through a static mixer and pumped into the microchannel reactor by a metering pump. The flow rate of the A\B mixed fluid in the microchannel is 1.46~7.13ml / min. The molar ratio of thiopropionaldehyde to hydrocyanic acid is 1:1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com