A heat-sensitive thin film of an uncooled infrared detector and its preparation method

An uncooled infrared and heat-sensitive thin film technology, which is applied in vacuum evaporation coating, coating, sputtering coating, etc., can solve the problems of defect amplification and difficult manufacture of detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

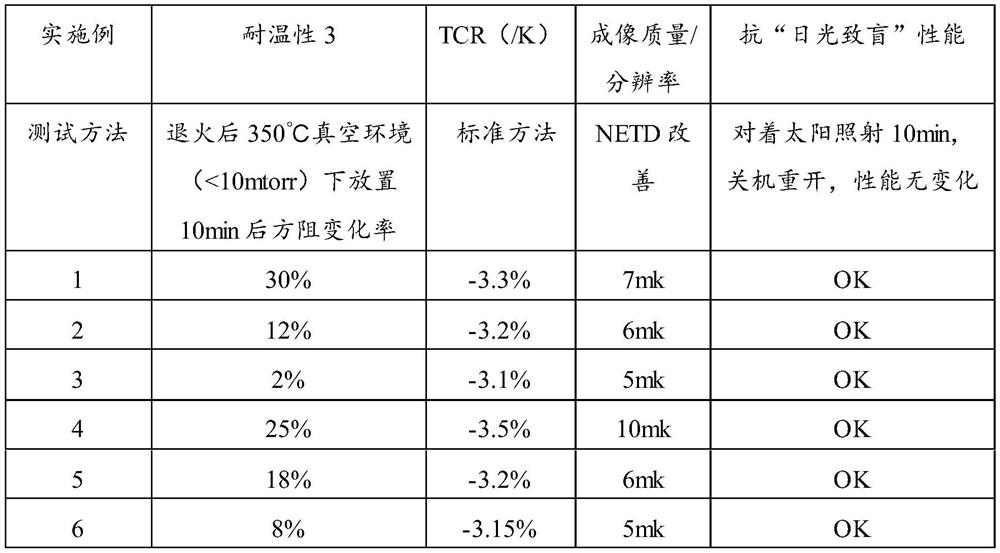

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a heat-sensitive thin film of an uncooled infrared detector, comprising the following steps:

[0038] A) Under a protective gas atmosphere, the main metal and the dopant metal are melted and forged to obtain an alloy target;

[0039] The alloy material includes 90-100wt% main metal and 0-10wt% doping metal,

[0040] The main metal is titanium and / or vanadium; the dopant metal is one or more of tungsten, cobalt and molybdenum;

[0041] B) Under an oxygen atmosphere, reactively sputtering the alloy target on the substrate to obtain an intermediate film; the oxygen participates in the reactive sputtering in the form of pulses;

[0042] The peak flow rate of the oxygen pulse is 2-10 sccm, and the trough flow rate of the oxygen pulse is 0.1-1 sccm;

[0043] C) annealing the intermediate film to obtain a heat-sensitive film for an uncooled infrared detector.

[0044] In the present invention, the main metal and the...

Embodiment 1

[0063] Under the Ar gas atmosphere, 49% Ti, 49% V and 2% tungsten are melted and forged in a high-purity furnace to obtain an alloy target;

[0064] The alloy target is installed on the deposition film machine, under the oxygen pulse, the reactive sputtering is carried out on the substrate, and the oxygen flow is quickly controlled by the pulse signal switch of the MFC (Mass flow controller): at the pulse valley value 0.5sccm and the pulse The cycle control is carried out within the peak value of 2sccm, and the time is 2s alternately, the sputtering temperature is 23°C, the sputtering power is 300W, the argon flow rate is 25sccm, the sputtering time is 400s, and the film thickness is obtained by sputtering

[0065] The obtained film was annealed at 300° C. for 50 min to obtain a heat-sensitive film for an uncooled infrared detector.

Embodiment 2

[0067] Under the Ar gas atmosphere, 90wt% Ti, 5wt% V and 5wt% molybdenum were melted and forged in a high-purity furnace to obtain an alloy target;

[0068] The alloy target is installed on the deposition film machine, under the oxygen pulse, the reactive sputtering is carried out on the substrate, and the oxygen flow is quickly controlled by the pulse signal switch of the MFC (Mass flow controller): at the pulse valley value 0.5sccm and the pulse The cycle control is carried out within the peak value of 5sccm, and the time is 4s alternately, the sputtering temperature is 100°C, the sputtering power is 600W, the argon flow rate is 30sccm, the sputtering time is 400s, and the film thickness is obtained by sputtering

[0069] The obtained film was annealed at 400° C. for 20 min to obtain a heat-sensitive film for an uncooled infrared detector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com