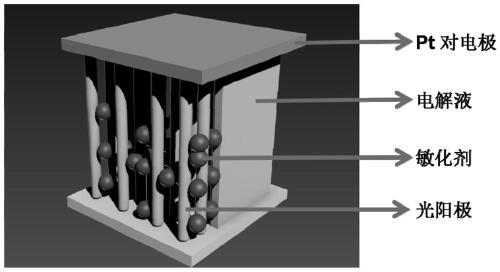

One-dimensional ultralong TiO2 nanorod array, preparation method thereof and application thereof in dye-sensitized solar cell

A nanorod array, solar cell technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy detachment of rods, short length of nanorods, small specific surface area, etc. Achieve the effect of optimizing the specific surface area, solving the small specific surface area, and increasing the short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

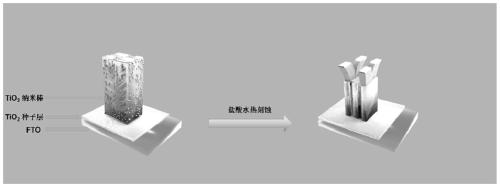

[0070] The one-dimensional ultra-long TiO of this embodiment 2 A method for preparing a nanorod array, the method comprising the steps of:

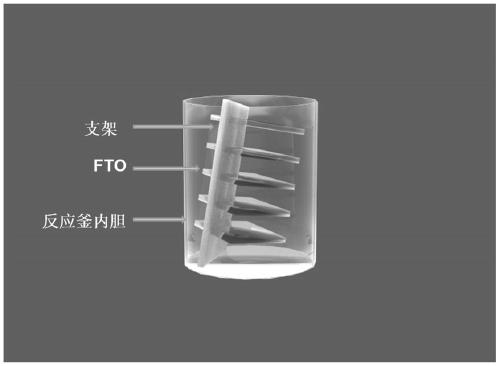

[0071] (1) Pretreatment of fluorine-doped tin oxide transparent conductive glass (FTO) substrate

[0072] The FTO conductive glass with a thickness of 2mm and a square structure of 2cm×2cm in length and width (the thickness of the conductive layer is 380nm) is ultrasonically cleaned with decontamination powder, deionized water, acetone, and isopropanol in sequence. Each step The time is 30 minutes, and the washed FTO base is directly put into a vacuum drying oven at 70°C for drying, and it is set aside.

[0073] (2) Titanium tetrachloride aqueous solution preparation

[0074] Prepare a solution concentration of 0.3mol L in a fume hood -1 Measure the titanium tetrachloride aqueous solution with a plastic dropper, slowly drop it into 500mL ice-water mixed deionized water at a height of 1 to 2 cm from the liquid surface, and keep stirring...

Embodiment 2

[0082] The one-dimensional ultra-long TiO of this embodiment 2 A method for preparing a nanorod array, the method comprising the steps of:

[0083] (1) Pretreatment of fluorine-doped tin oxide transparent conductive glass (FTO) substrate

[0084] The FTO conductive glass with a thickness of 2mm and a square structure of 2cm×2cm in length and width (the thickness of the conductive layer is 380nm) is ultrasonically cleaned with decontamination powder, deionized water, acetone, and isopropanol in sequence. Each step The time is 30 minutes, and the washed FTO base is directly put into a vacuum drying oven at 70°C for drying, and it is set aside.

[0085] (2) Titanium tetrachloride aqueous solution preparation

[0086] Prepare a solution concentration of 0.3mol L in a fume hood -1 Measure the titanium tetrachloride aqueous solution with a plastic dropper, slowly drop it into 250mL ice-water mixed deionized water at a height of 1 to 2 cm from the liquid surface, and keep stirring...

Embodiment 3

[0094] The one-dimensional ultra-long TiO of this embodiment 2 A method for preparing a nanorod array, the method comprising the steps of:

[0095] (1) Pretreatment of fluorine-doped tin oxide transparent conductive glass (FTO) substrate

[0096] The FTO conductive glass with a thickness of 2mm and a square structure of 2cm×2cm in length and width (the thickness of the conductive layer is 380nm) is ultrasonically cleaned with decontamination powder, deionized water, acetone, and isopropanol in sequence. Each step The time is 30 minutes, and the washed FTO base is directly put into a vacuum drying oven at 70°C for drying, and it is set aside.

[0097] (2) Titanium tetrachloride aqueous solution preparation

[0098] Prepare a solution concentration of 0.3mol L in a fume hood -1 Measure the titanium tetrachloride aqueous solution with a plastic dropper, slowly drop it into 100mL of ice-water mixed deionized water at a height of 1 to 2 cm from the liquid surface, and keep stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com