A method for preparing ammonia by using ammonia synthesis-biomass conversion dual-functional photocatalytic reaction

A photocatalytic reaction and biomass technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation/separation of ammonia, etc., can solve the problem of low photocatalyst photogenerated electron-hole separation and migration efficiency and low molecular reactivity , low reaction efficiency and other issues, to achieve high yield, high raw material utilization, and improved thermodynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]This embodiment prepares Zn deficiency-Zn according to the following steps 3 In 2 S 6 nanomaterials:

[0031] Step 1, weigh 1.5mmol of zinc nitrate, 1mmol of indium nitrate hydrate and 3mmol of cysteine in a beaker filled with 60mL of deionized water, and stir to dissolve them;

[0032] Step 2, transfer the mixture in step 1 to a 100ml polytetrafluoroethylene liner, seal it, heat it with water at 200°C, and after 20 hours, wash it with deionized water and dry it in vacuum to obtain the Zn defect-Zn 3 In 2 S 6 nanomaterials.

[0033] Other surface defect modified transition metal dichalcogenides (TMDs) such as Cd defect-CdIn 2 S 4 , Cd defect-CdLa 2 S 4 , Zn defect-Cd x Zn 1-x S(x=0-1) and Zn defects-Zn x In 2 S 3+x (x=1-5) and the like can be prepared by changing the raw materials and process conditions and adopting the above-mentioned preparation method. Among them, the raw materials of metal elements are their nitrates, and the ratio of raw materials i...

Embodiment 2

[0049] This example is the same as Example 1, except that the hydrothermal temperature in step 2 is 180°C, and Zn 3 In 2 S 6 nanomaterials.

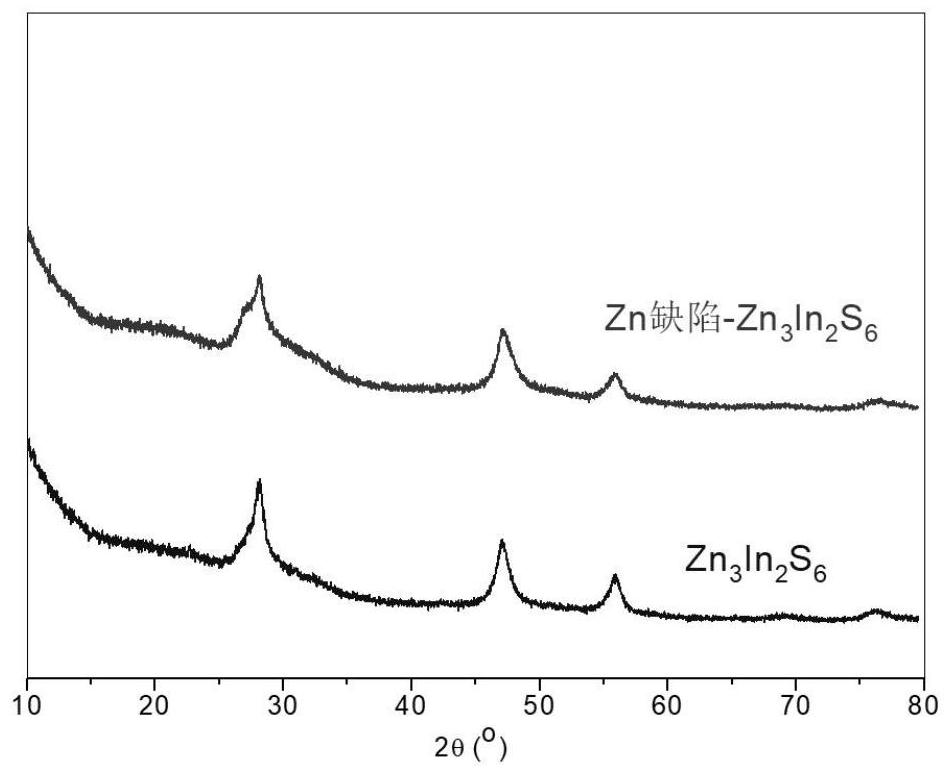

[0050] For the Zn defect-Zn prepared by Example 1 of the present invention 3 In 2 S 6 And the Zn that embodiment 2 prepares 3 In 2 S 6 Nanomaterials were characterized, and the results were as follows figure 1 , figure 2 , image 3 and Figure 4 shown. in, figure 1 X-ray diffraction (XRD) pattern, Zn defect-Zn 3 In 2 S 6 and Zn 3 In 2 S 6 All the diffraction peaks in the diffraction pattern correspond well to the hexagonal phase Zn 3 In 2 S 6 . Illustrates the pure phase of Zn 3 In 2 S 6 was successfully prepared, and the Zn-defects did not cause the generation of new material phases.

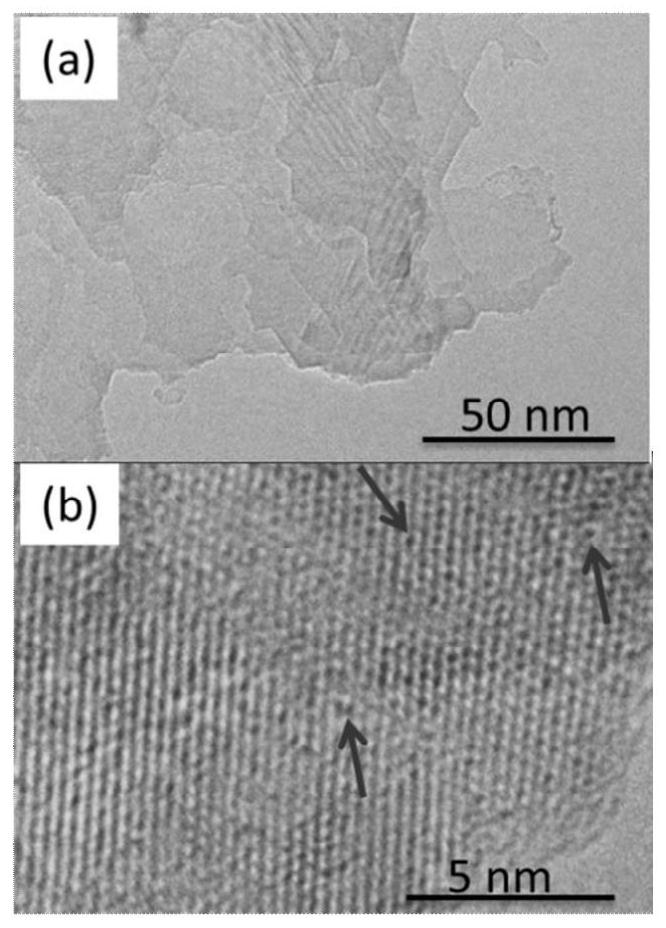

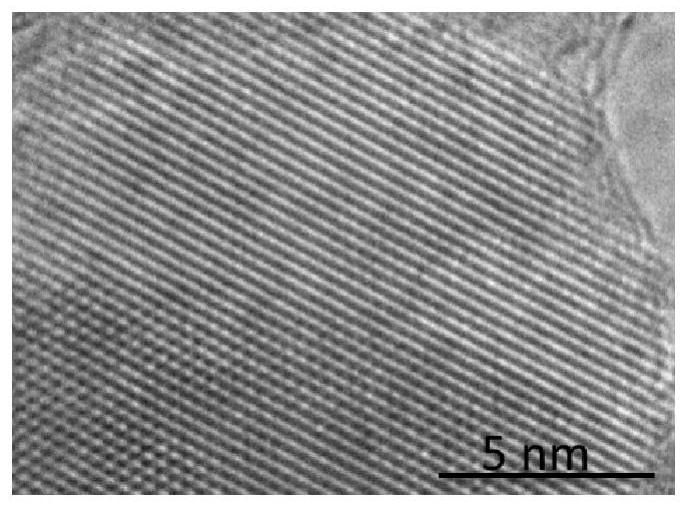

[0051] figure 2 Zn defect-Zn 3 In 2 S 6 The transmission electron microscope (TEM) and high-resolution transmission electron microscope (HRTEM) images of the sample, it can be seen from the figure that the sample is an ultr...

Embodiment 3

[0055] This example is the construction of a bifunctional reaction system (benzyl alcohol is used in the mixed solution of biomass and water containing alcoholic hydroxyl groups), and the detailed steps are as follows:

[0056] Step 1, add 0.03g of Zn defect-Zn 3 In 2 S 6 Nanomaterials and 50mL of benzyl alcohol were added to a 100mL three-port polytetrafluoroethylene reactor;

[0057] Step 2, feed N into the reactor 2 After evacuating the air, keep the N in the reactor 2 The pressure is about 0.2Mpa;

[0058] Step 3: After stirring for about 0.5 h in the dark state to balance the adsorption and desorption, turn on the visible light source, extract 5 mL of the reaction solution every 1 hour, centrifuge, and analyze and detect the liquid phase products in the reaction solution such as ammonia and aldehydes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com