System and method for improving regeneration and reuse rate of acid etching solutions

A technology for acid etching liquid and acid etching waste liquid, which is applied in separation methods, process efficiency improvement, chemical instruments and methods, etc., can solve the problems of environmental pollution, waste of water resources, and low recycling rate of etching waste liquid, etc. Achieve the effect of improving the regeneration and reuse rate, reducing the discharge of wastewater, and the prospect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

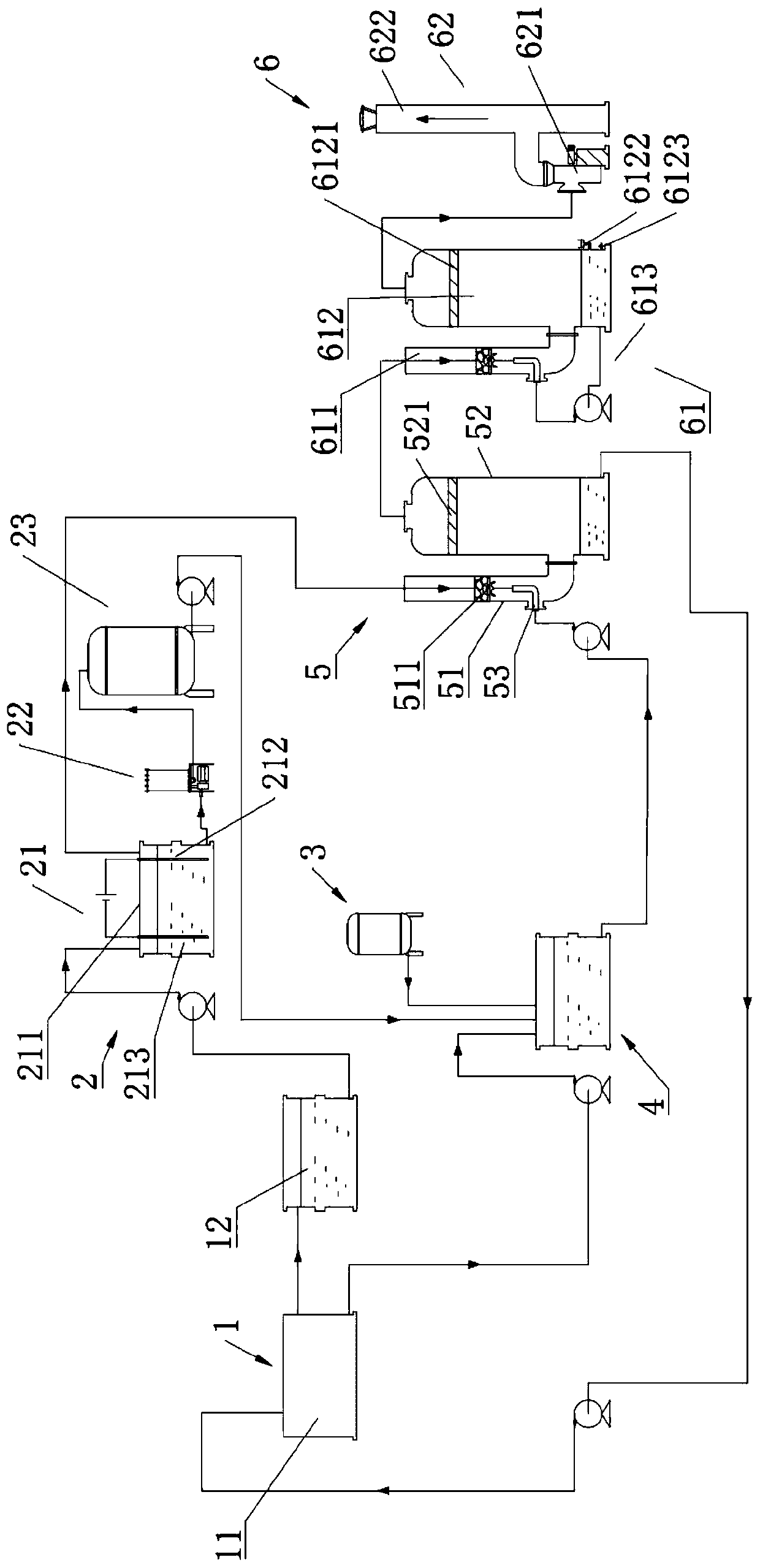

[0034] refer to figure 1 , figure 1 It is a schematic structural diagram of a system for increasing the recycling rate of acidic etching liquid in this embodiment. The system for improving the recycling rate of acidic etching liquid in this embodiment includes an etching production line 1 , an electrolysis device 2 , an adding device 3 , a regeneration liquid preparation device 4 and a regeneration liquid ORP raising device 5 . Etching production line 1 etches PCB boards, and outputs copper-rich acidic etching waste and low ORP acidic etching solution. The electrolysis device 2 receives and electrolyzes the copper-rich acidic etching waste liquid output from the etching production line 1, and outputs copper-poor electrolytic liquid, copper and chlorine gas. Adding device 3 is used to provide additives. The regenerated solution preparation device 4 receives and mixes the low ORP acidic etching solution output from the etching production line 1, the copper-poor electrolytic c...

Embodiment 2

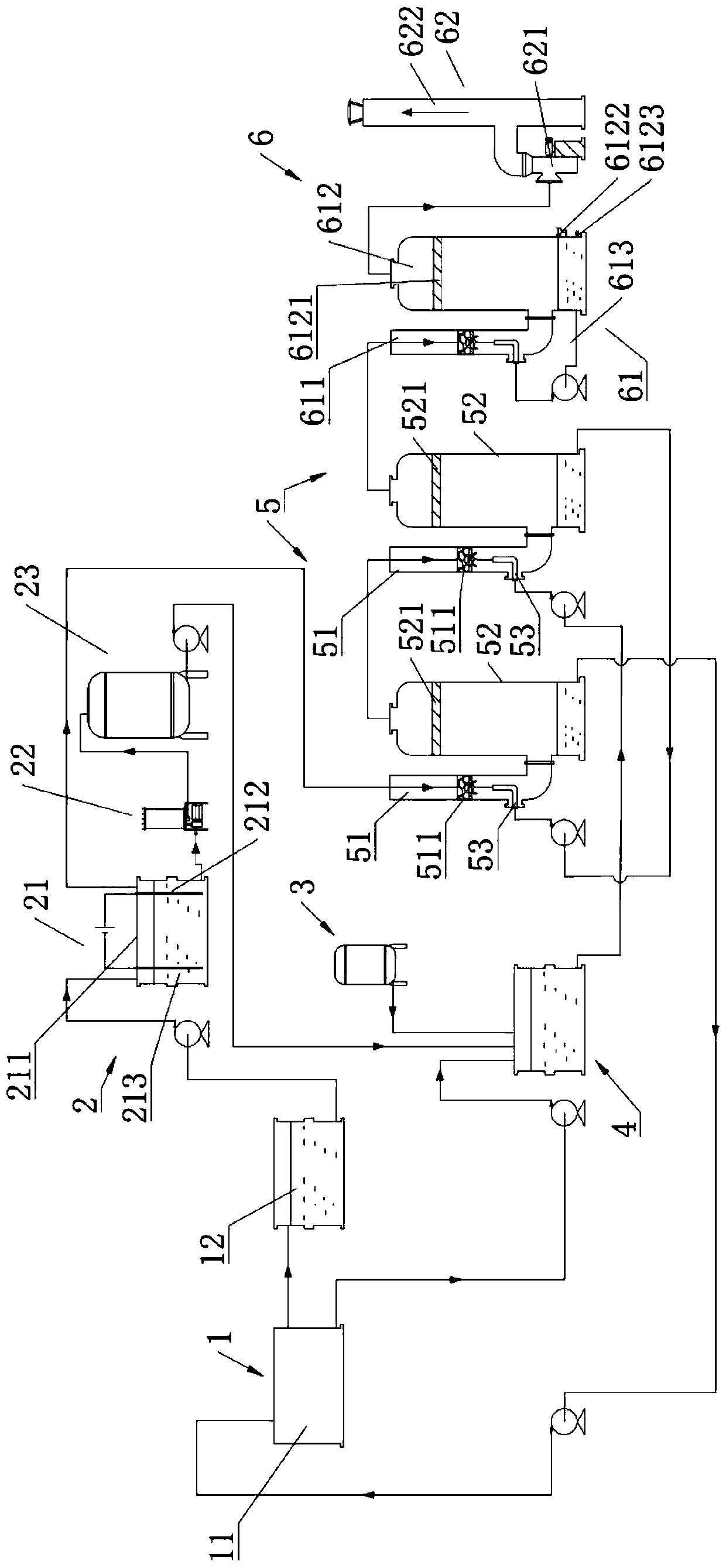

[0054] refer to figure 2 , figure 2 It is a schematic structural diagram of a system for improving the regeneration rate of acidic etching liquid in Example 2. The difference between the system for increasing the recycling rate of acidic etching liquid in this embodiment and that in Embodiment 1 is that there are two regeneration liquid ORP lifting devices 5 .

[0055] Among the two regeneration liquid ORP lifting devices 5, the upper end of the power wave tube 51 of one of the regeneration liquid ORP lifting devices 5 communicates with the electrolysis device 2, and the countercurrent injection part 53 of the other regeneration liquid ORP lifting device 5 communicates with the regeneration liquid blending device 4 The upper end of the tank body 52 of one regeneration liquid ORP lifting device 5 communicates with the upper end of the power wave tube 51 of another regeneration liquid ORP lifting device 5, and the lower end of the tank body 52 of another regeneration liquid O...

Embodiment 3

[0058] The method for improving the recycling rate of acidic etching solution in the present embodiment comprises the following steps:

[0059] Etching production line 1 etches PCB boards to obtain low ORP acidic etching solution and copper-rich acidic etching waste solution.

[0060] The electrolysis device 2 electrolyzes copper-rich acidic etching waste liquid to obtain copper-poor electrolytic clear liquid, copper and chlorine gas.

[0061] The low ORP acidic etching solution is mixed with the copper-poor electrolytic clear solution, and additives are added to obtain a regenerated acidic etching solution.

[0062] The regenerated acidic etching solution is sprayed countercurrently through the countercurrent jetting member 53 and then collides with chlorine gas to form atomized foam.

[0063] After the atomized foam passes through the oxidizing solution, it forms a high ORP acidic etching regeneration solution and returns it to the etching production line 1.

[0064] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com