Lightweight slightly ablative composite material, and preparation method thereof

A composite material and lightweight technology, which is applied in the field of lightweight micro-ablative composite materials and their preparation, can solve the problems of low thermal decomposition temperature, composite material damage, and strength reduction, and achieve high melting point, enhanced structural strength, and strength and the effect of increasing the carbon residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

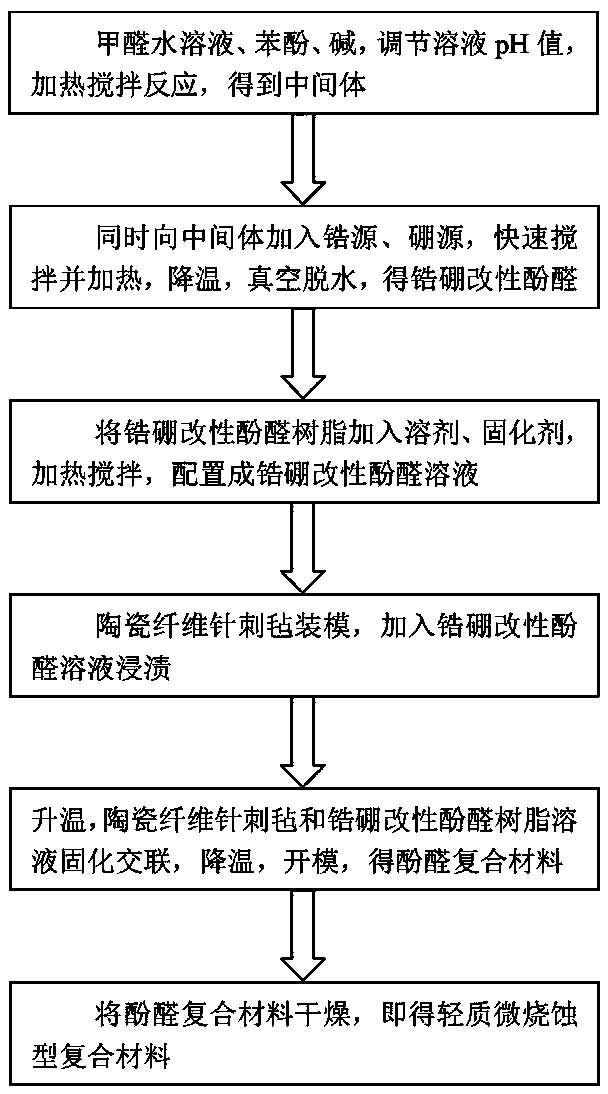

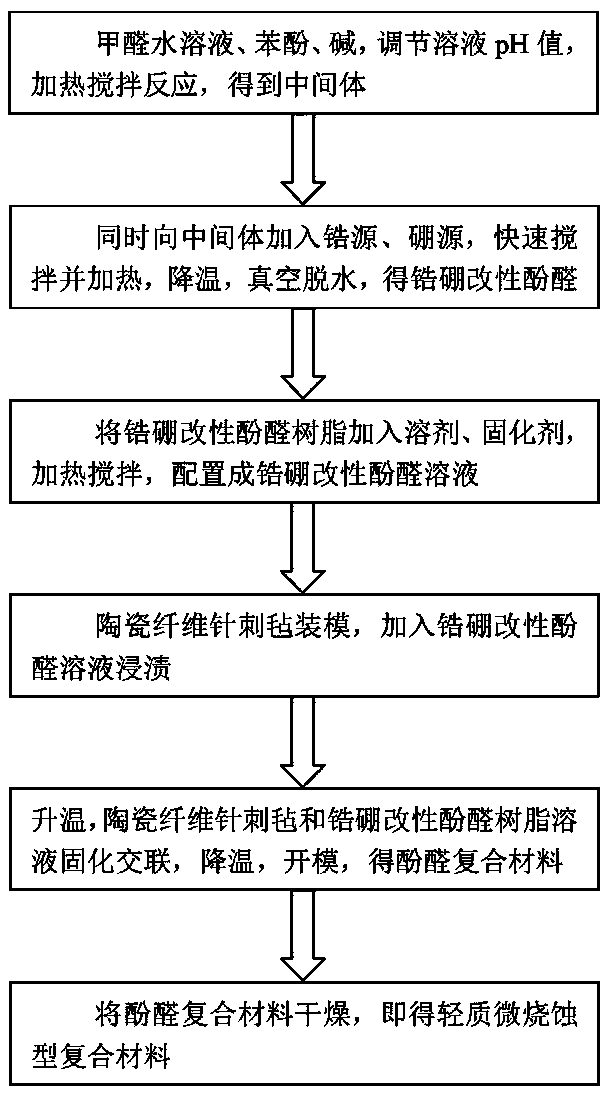

[0035] Such as figure 1 As shown, the preparation method of a light-weight micro-ablative composite material in this embodiment includes the following steps:

[0036] (1) Resin synthesis: first add 37% formaldehyde solution and phenol, the molar ratio of the two is 1.2:1, that is, weigh 97.3g of 37% formaldehyde solution and 94.1g of phenol, put them into a three-necked flask with a condenser, stir, Add sodium hydroxide to adjust the pH value to 8, raise the temperature to 70°C, and react for 3 hours; continue to add zirconium oxychloride and triisopropyl borate into the three-necked flask at the same time, and the molar mass of zirconium oxychloride is 5 times that of phenol. %, namely 8.91g, the molar mass of triisopropyl borate is 10% of the molar mass of phenol, namely 18.81g, heated up to 93°C, reacted for 3h under the condition of reflux and stirring, cooled to room temperature, and dehydrated in vacuum to obtain solid zirconium boron modified phenolic resin.

[0037] ...

Embodiment 2

[0043] A method for preparing a lightweight micro-ablative composite material in this embodiment comprises the following steps:

[0044] (1) Resin synthesis: first add 37% formaldehyde solution and phenol, the molar ratio of the two is 1.5:1, that is, weigh 121.6g of 37% formaldehyde solution and 94.1g of phenol, put them into a three-necked flask with a condenser, and stir. Add sodium hydroxide as a catalyst, adjust the pH value to 8, raise the temperature to 72°C, and react for 3 hours; continue to add zirconium oxychloride and triisopropyl borate to the three-necked flask at the same time, and the molar mass of zirconium oxychloride is that of phenol 8% of the molar mass, i.e. 14.35g, the molar mass of triisopropyl borate is 8% of the molar mass of phenol, i.e. 15.04g, heated up to 95°C, reacted for 3h under reflux and stirring conditions, cooled, and vacuum dehydrated to obtain Solid zirconium boron modified phenolic resin.

[0045] (2) Preparation of phenolic impregnatio...

Embodiment 3

[0051] A method for preparing a lightweight micro-ablative composite material in this embodiment comprises the following steps:

[0052] (1) Resin synthesis: first add 37% formaldehyde solution and phenol, the molar ratio of the two is 1.3:1, that is, weigh 105.4g of 37% formaldehyde solution and 94.1g of phenol, put them into a three-necked flask with a condenser, and stir. Add an appropriate amount of sodium hydroxide as a catalyst, adjust the pH value to 9, raise the temperature to 70°C, and react for 2 hours; continue to add zirconium oxychloride and triisopropyl borate to the three-necked flask at the same time, and the molar mass of zirconium oxychloride is 20% of the molar mass of phenol, which is 35.87g, and the molar mass of triisopropyl borate is 5% of the molar mass of phenol, which is 9.41g. Heating up to 92°C, reacting for 2.5h under reflux and stirring conditions, cooling down, vacuum After dehydration, a solid zirconium boron modified phenolic resin is obtained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com