Thermal spraying powder

A technology of thermal spraying powder and graphene powder, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of poor self-lubricating performance of graphene-ceramic coating, and achieve easy industrial operation and high hardness The effect of improving and good self-lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 1. Preparation of thermal spray powder:

[0036] 1. Preparation of alumina-coated graphene powder:

[0037] Weigh 0.4g graphene (Nanjing Xianfeng Nano Material Technology Co., Ltd.) at room temperature, add it to 200mL ethanol, and sonicate for 2h. Another 14.49g (0.06mol) AlCl was weighed 3 ·6H 2 O, dissolved in 200mL deionized water, and then the two solutions were mixed and continued to stir in an ultrasonic bath for 30min. Add ammonia water dropwise to the above mixture until pH = 9 to generate Al(OH) 3 gel. The gel was centrifuged and washed three times with 50% ethanol aqueous solution, dried at 80°C for 12h and crushed, then burned at 1200°C under the protection of inert gas for 4h, ground and passed through a 0.075mm sieve to obtain alumina-coated graphene powder (ACG) , the theoretical mass fraction of graphene is 11.6%.

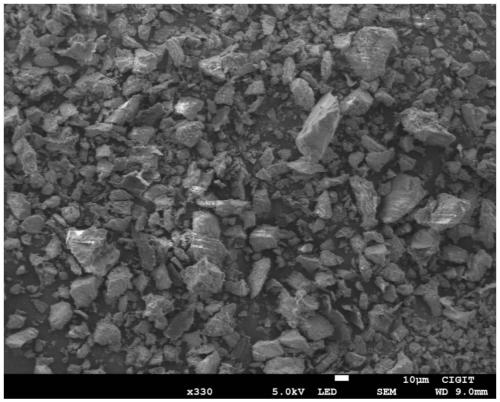

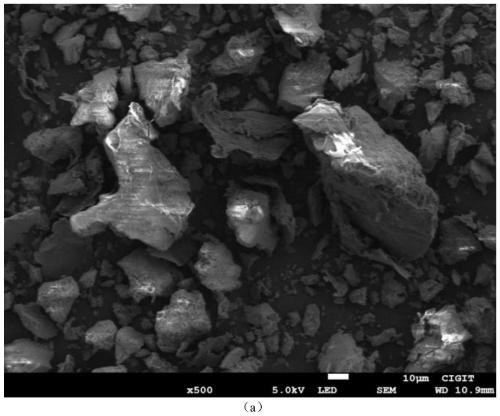

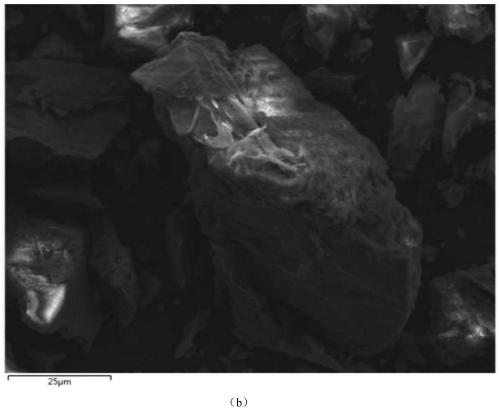

[0038] see figure 1 ,from figure 1 It can be seen that the coating of alumina on graphene is relatively uniform and complete, and th...

Embodiment 1

[0044] Mix 8.7g ACG, 1.3g TCG (containing 1g graphene in total) with 90g AT-13 spray powder, add 500mL of absolute ethanol, stir in an ultrasonic bath for 2h, and dry at 80°C for 12h to obtain a graphene containing 1% mass fraction. Mixed powder, namely AT-13+ACG, TCG mixed powder, recorded as ATG-1.

[0045] Use plasma spraying equipment to spray the coating on the 304 stainless steel substrate. When spraying, the flame gun is 15cm away from the substrate, and the spraying time is 30s. Repeat 4 times. The size of the substrate is 25×25×5mm. Before spraying the ceramic coating, it is sandblasted and sprayed with a transition layer. The sandblasting pressure is 0.6-0.7MPa. 24 mesh white corundum sand is used. The transition layer is NiAl alloy, and the mass ratio of Ni and Al is It is 2:8.

Embodiment 2

[0047] Mix 15.2 g ACG, 2.2 g TCG (containing 2 g graphene in total) with 82.6 g AT-13 spraying powder, add 500 mL of absolute ethanol, stir in an ultrasonic bath for 2 h, and dry at 80 ° C for 12 h to obtain graphite with a mass fraction of 2%. The mixed powder of alkene is recorded as ATG-2.

[0048] Use plasma spraying equipment to spray the coating on the 304 stainless steel substrate. When spraying, the flame gun is 15cm away from the substrate, and the spraying time is 30s. Repeat 4 times. The size of the substrate is 25×25×5mm. Before spraying the ceramic coating, it is sandblasted and sprayed with a transition layer. The sandblasting pressure is 0.6-0.7MPa. 24 mesh white corundum sand is used. The transition layer is NiAl alloy, and the mass ratio of Ni and Al is It is 2:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com