Gas sensor based on nickel sulfide nano composite material and preparation method of gas sensor

A technology of nanocomposite materials and gas sensors, applied in chemical instruments and methods, nickel sulfide, analytical materials, etc., can solve the problems of poor timeliness and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

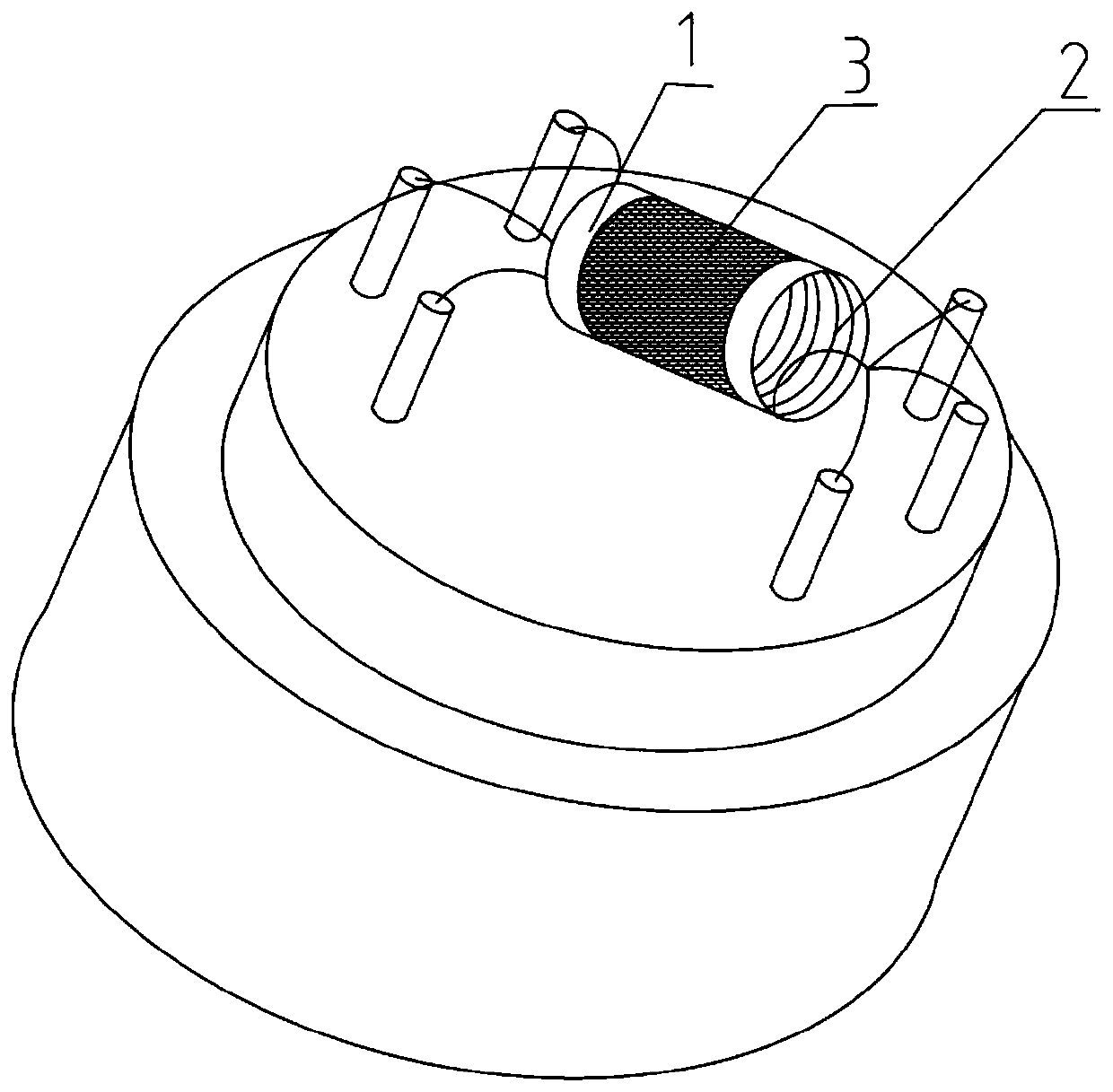

[0060] The gas sensor based on the nickel sulfide nanocomposite material that this embodiment relates to, its main structure comprises the Al with 2 discrete annular gold electrodes on the outer surface. 2 o 3 Insulating ceramic tube, through Al 2 o 3 The nickel-cadmium alloy coil inside the insulating ceramic tube and the Al-coated 2 o 3 The outer surface of the insulating ceramic tube and the sensitive material film on the ring gold electrode are composed of NiS nanocomposite material.

[0061] The preparation method of the gas sensor based on the nickel sulfide nanocomposite material involved in this embodiment includes: thoroughly grinding the NiS nanocomposite material in an agate mortar to obtain a pasty gas-sensitive paste, and then evenly coating the gas-sensitive paste on the Al of the gas sensor 2 o 3 Finally, vacuum-dry at 60°C overnight to prepare a gas sensor of nickel sulfide nanocomposite.

[0062] The specific preparation process of the NiS nanocomposite...

Embodiment 2

[0067] The gas sensor based on nickel sulfide nanocomposites involved in this embodiment is specifically NiS@In 2 o 3 Gas sensor, NiS@In 2 o 3 The main structure of the gas sensor consists of Al with 2 discrete annular gold electrodes on the outer surface 2 o 3 Insulated ceramic tube 1, passing through Al 2 o 3 The nickel-cadmium alloy coil 2 inside the insulating ceramic tube and coated in Al 2 o 3 The outer surface of the insulating ceramic tube and the sensitive material film 3 on the annular gold electrode, the sensitive material is NiS@In 2 o 3 nanocomposites.

[0068] The NiS@In involved in this embodiment 2 o 3 The preparation method of the gas sensor, the specific process steps are as follows:

[0069] Step 1: Prepare NiS nanofibers: Ni(NO 3 ) 2 NiS nanofibers were prepared by electrospinning technology combined with hydrogen sulfide calcination; the specific steps are as follows:

[0070] (1) The PVP of 2.2g is dissolved in the DMF solvent of 20ml, and ...

Embodiment 3

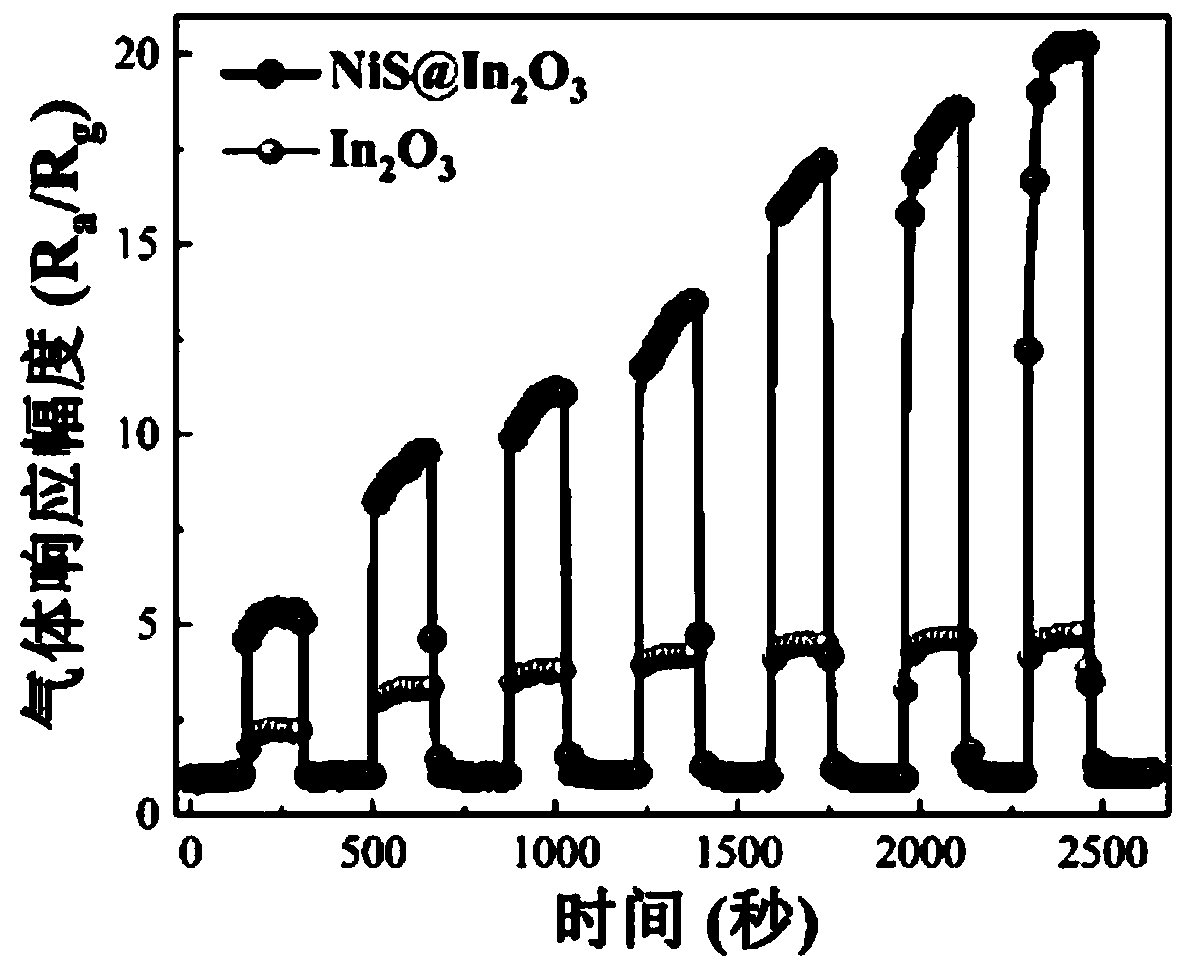

[0088] In this example, three groups of NiS@In prepared in Example 2 2 o 3 Gas sensor performance test, the In 2 o 3 Grind thoroughly in an agate mortar to prepare a paste-like gas-sensitive paste; then apply the gas-sensitive paste evenly on the gas sensor Al 2 o 3 ceramic tube 1 and dried under vacuum at 60 °C overnight to obtain In 2 o 3 gas sensor, the In 2 o 3 Gas sensor with NiS@In 2 o 3 The performance of the gas sensor is tested by comparative experiments; here, the gas response range of the gas sensor is defined as S=R a / R g , where R a is the resistance in air, R g is the resistance in the gas to be measured, and in addition, the response or recovery time is 90% of the time it takes for the gas sensor output to reach its saturated state after the gas is applied or turned off.

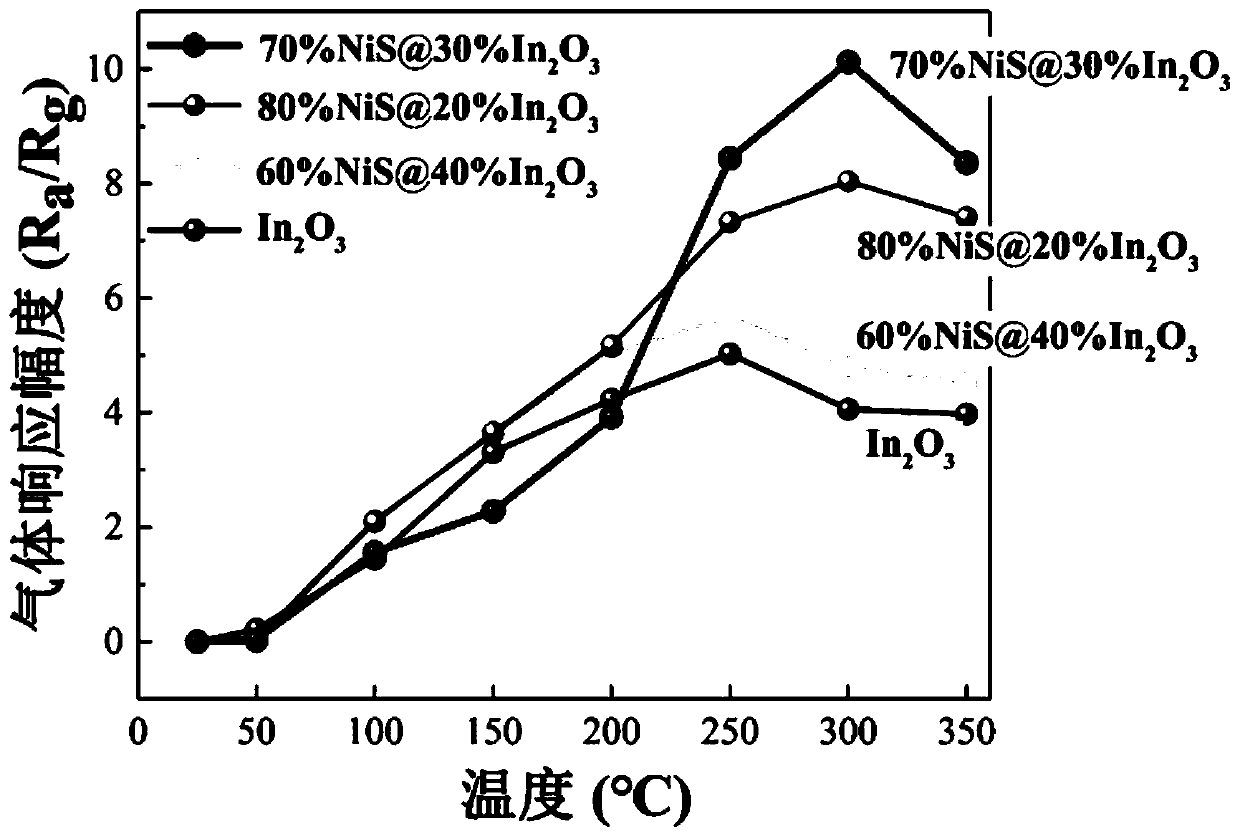

[0089] Such as figure 2 As shown, the In 2 o 3 Gas sensor, 60%NiS@40%In 2 o 3 Gas sensor, 70%NiS@30%In 2 o 3 Gas sensor and 80%NiS@20%In 2 o 3 The gas sensor measures the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com