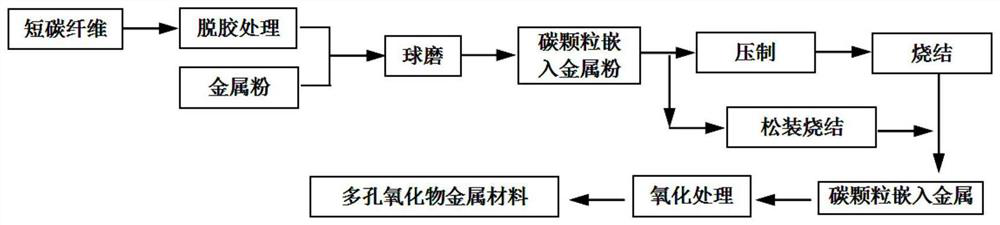

A kind of preparation method of porous metal oxide

A porous metal and oxide technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of difficult removal of templates, low production efficiency, and high production costs, and achieve good market prospects, excellent performance, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

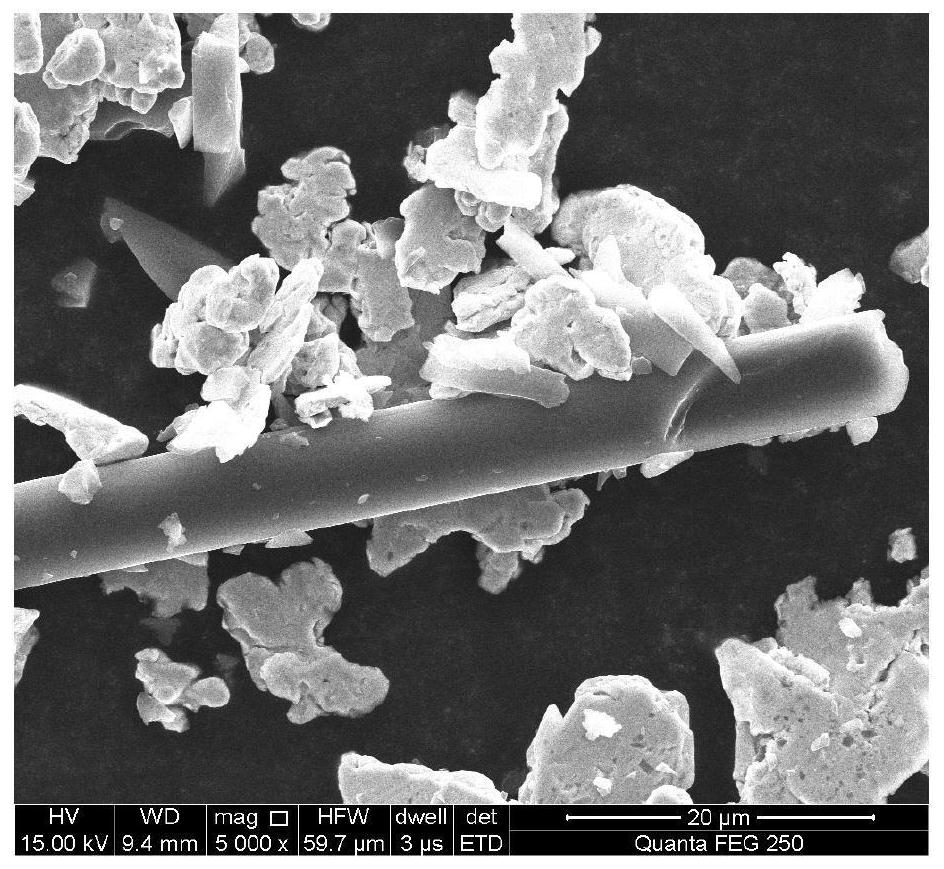

[0062] In this example 1, commercially available short carbon fibers that have been degummed at 700°C for 60 minutes and electrolytic copper powder with a particle size of 120 μm are used as ball milling raw materials. The volume percentage of short carbon fibers is 10%, and the volume percentage of electrolytic copper powder is 90%. The diameter is 6 μm, and the length is 2 mm. The two are added to a ball mill for high-energy ball milling at a speed of 250 r / min, a ball milling time of 6 hours, and a ball-to-material ratio of 6:1. The obtained mixed powder was cold-pressed at room temperature, the pressing pressure was 50 MPa, and the holding time was 20s. The prepared carbon particles embedded in the copper compact were sintered under the protection of a hydrogen atmosphere, and sintered at 900 ° C for 1 hour. The heating rate and cooling rate of the furnace Both are at 15°C / min, and then the sintered body is annealed in air to remove carbon and oxidize. The annealing tempera...

Embodiment 2

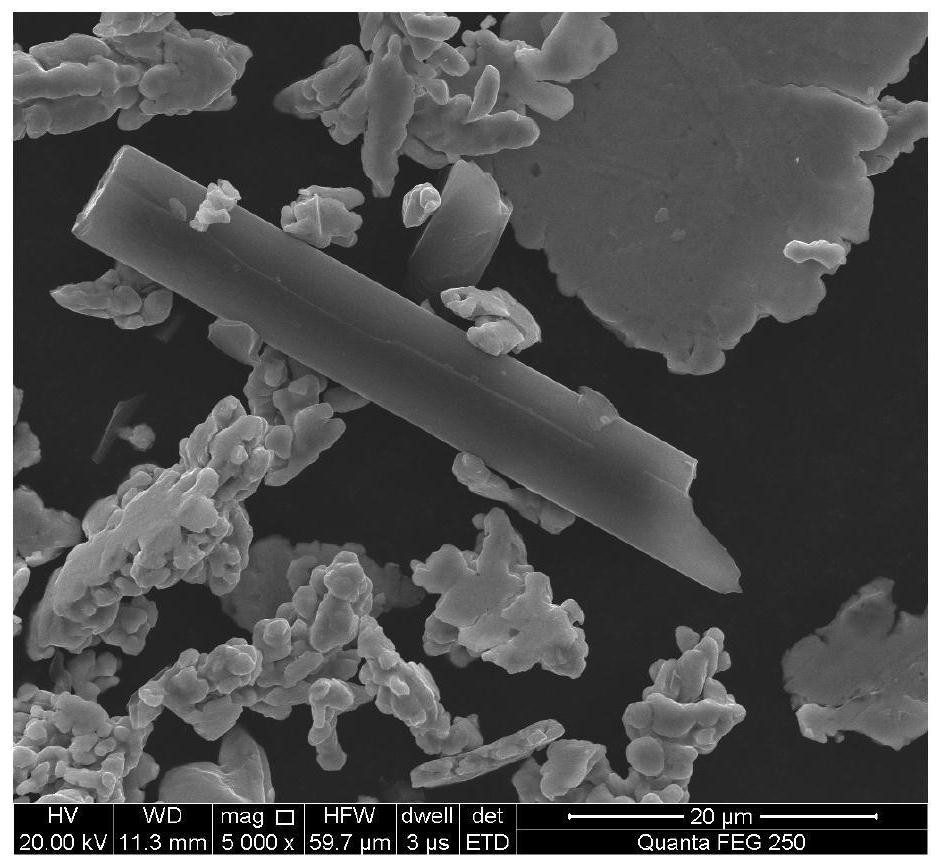

[0064]In Example 2, commercially available short carbon fibers that have been degummed at 750°C for 60 minutes and electrolytic nickel powder with a particle size of 120 μm are used as ball milling raw materials. The volume percentage of short carbon fibers is 25%, and the volume percentage of electrolytic nickel powder is 75%. The diameter is 6 μm, the length is 2 mm, and the two are added to a ball mill for high-energy ball milling at a speed of 280 r / min, a ball milling time of 7 hours, and a ball-to-material ratio of 6:1. The obtained mixed powder is directly sintered under the protection of a hydrogen atmosphere, and sintered at 850°C for 1 hour. The heating rate and cooling rate of the furnace are both 15°C / min, and then the sintered body is annealed in air to remove carbon and oxidize, and the annealing temperature is 500°C , the holding time is 30min, the porosity of the obtained porous nickel oxide reaches 22-30%, and the content of the nickel oxide is 90% of the total...

Embodiment 3

[0066] In Example 3, commercially available short carbon fibers that have been degummed at 800°C for 60 minutes and reduced iron powder with a particle size of 150 μm are used as raw materials for ball milling. The volume percentage of short carbon fibers is 40%, and the volume percentage of reduced iron powder is 60%. The diameter is 6 μm, the length is 2 mm, and the two are added to a ball mill for high-energy ball milling at a speed of 300 r / min, a ball milling time of 8 hours, and a ball-to-material ratio of 6:1. The obtained mixed powder is directly sintered under vacuum, and sintered at 980°C for 1 hour. The heating rate and cooling rate of the furnace are both 15°C / min. The time is 60 minutes, and the porosity of the obtained porous iron oxide reaches 40-48%, and the iron oxide content is 85% of the total mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com