Aqueous polyurethane acrylate dispersion and preparation method thereof, coating material with self-healing performance

A technology of urethane acrylate and acrylate, which is applied in the field of coating materials, can solve problems such as scratches or cracks on the surface of objects, which affect the appearance, and achieve good cracks and scratches, automatic repair of cracks and scratches, and good dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of aqueous polyurethane acrylate dispersion, comprising:

[0022] S1. Preparation of polyurethane prepolymer: react diisocyanate with polyester polyol or polyether polyol to obtain polyurethane prepolymer. The ratio of the amount of substance is 8~11:1.

[0023] Specifically, add diisocyanate and polyester polyol, or add diisocyanate and polyether polyol in the reactor, the ratio of the amount of isocyanate group and hydroxyl substance in the added diisocyanate and polyester polyol is 8~11: 1. The ratio of the amount of diisocyanate and polyether polyol to the amount of isocyanate group to hydroxyl substance is 8 to 11:1, and the temperature of the reactor is raised to 60 to 90 ° C, and the reaction is performed for 0.5 to 2.5 hours to obtain a polyurethane prepolymer. It should be noted that, in the present invention, it is also possible to first make the reaction kettle warm up to the required temperature, and then add diisocyanate and polyester ...

Embodiment 1

[0061] This embodiment provides a water-based polyurethane acrylate dispersion, a preparation method thereof, and a finishing material with self-healing properties.

[0062] A kind of preparation method of aqueous polyurethane acrylate dispersion, concrete operation is as follows:

[0063] Add isophorone diisocyanate and polyadipate 1,4 butanediol polyester diol (molecular weight 1000) in the reactor, the added isophorone diisocyanate and polyadipate 1,4 butanediol The ratio of the amount of isocyanate group to hydroxyl substance in alcohol polyester diol (molecular weight 1000) is 8:1. Then raise the temperature of the reactor to 85° C., and react for 1.5 hours to obtain a polyurethane prepolymer.

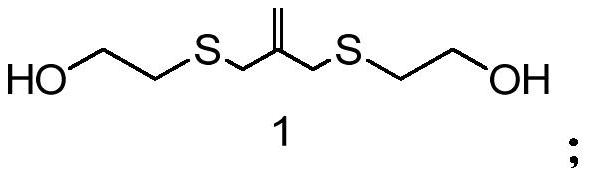

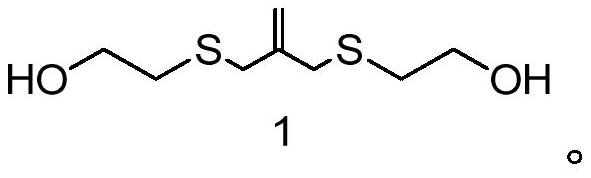

[0064] With methanol as a solvent and sodium methoxide as a catalyst, mercaptoethanol (change mercaptoethanol to 3-mercapto-1-propanol, 4-mercapto-1-butanol to obtain the other two)) and 3-chloro-2- The molar ratio of chloromethyl-1-propylene is 2:1, and the mixture is reacted u...

Embodiment 2

[0073] This embodiment provides a water-based polyurethane acrylate dispersion, a preparation method thereof, and a finishing material with self-healing properties.

[0074] A kind of preparation method of aqueous polyurethane acrylate dispersion, concrete operation is as follows:

[0075] Add hexamethylene diisocyanate and polytetrahydrofuran diol into the reaction kettle, and the ratio of the amount of isocyanate group to hydroxyl substance in the added hexamethylene diisocyanate and polytetrahydrofuran diol is 11:1. Then raise the temperature of the reactor to 60° C., and react for 3.5 hours to obtain a polyurethane prepolymer.

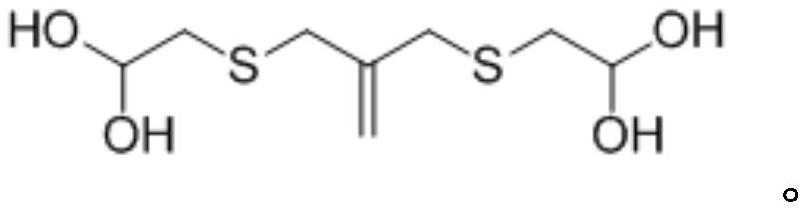

[0076] Water tetrahydrofuran is used as a solvent, sodium hydride is used as a catalyst, dihydroxypropylene mercaptan and 3-chloro-2-chloromethyl-1-propene are mixed at a ratio of 2:1, and react at room temperature to obtain allylsulfide-containing The tetrahydroxy compound of ether group, the chemical formula of this tetrahydroxy compound is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com