Preparation method of soybean protein-based two-component adhesive for wood

A technology of wood adhesive and soybean protein, which is applied in the direction of carboxyl rubber adhesive, adhesive, asphalt material adhesive, etc., can solve the problems of low cohesive force, inability to adapt to modern large-scale industrial production, poor water resistance, etc., to achieve Enhanced adhesion, reduced water absorption, and high conjunctiva strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

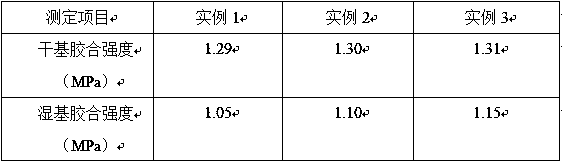

Embodiment 1

[0031] Knead the pretreated steel wire and cable fiber to obtain a high-strength weather-resistant ship cable. The preparation steps of the pretreatment steel wire are: evenly coating the surface of the steel wire with urotropine, and drying naturally to obtain the pretreatment steel wire. The cable fiber is mixed evenly with sodium lauryl sulfate, 40% sodium hydroxide solution and 40% calcium hydroxide according to the mass ratio of 1:2:2 to obtain the mixed modification solution; according to the mass ratio of 1 : 5 mix soybean protein powder and deionized water, stir in the water bath for 20min at a water bath temperature of 50°C and at a stirring speed of 200r / min to obtain a mixed solution, add the mixed modifying solution to the mixed solution at a mass ratio of 1:10 , and continue stirring in a water bath for 1 hour to obtain the base liquid; in parts by weight, weigh 20 parts of the base liquid, 1 part of acrylic acid, 1 part of carboxymethyl cellulose, and 1 part of N...

Embodiment 2

[0033] According to the mass ratio of 1:2:2, the sodium lauryl sulfate, the mass fraction of 40% sodium hydroxide solution and the mass fraction of 40% calcium hydroxide are mixed evenly to obtain the mixed modified solution; according to the mass ratio of 1:5 Mix soybean protein powder and deionized water, and stir in a water bath at a temperature of 55°C and a stirring speed of 250r / min for 25 minutes to obtain a mixed solution. Add a mixed modifying solution to the mixed solution at a mass ratio of 1:10, and continue Stir in a water bath for 1.5 hours to obtain the base liquid; in parts by weight, weigh 25 parts of the base liquid, 5 parts of acrylic acid, 3 parts of carboxymethyl cellulose, 2 parts of N,N'-methylenebisacrylamide, 0.6 parts of ammonium persulfate, 3 parts of urea, 0.2 parts of 2-mercaptoethanol, 2 parts of acetone, 7 parts of absolute ethanol, 40 parts of deionized water, gelatinize the base liquid at a temperature of 55°C for 7 minutes to obtain a paste Fo...

Embodiment 3

[0035] According to the mass ratio of 1:2:2, the sodium lauryl sulfate, the mass fraction of 40% sodium hydroxide solution and the mass fraction of 40% calcium hydroxide are mixed evenly to obtain the mixed modified solution; according to the mass ratio of 1:5 Mix soybean protein powder and deionized water, stir in a water bath at a temperature of 60°C and a stirring speed of 300r / min for 30 minutes to obtain a mixed solution, add a mixed modifying solution to the mixed solution at a mass ratio of 1:10, and continue Stir in a water bath for 2 hours to obtain the base liquid; in parts by weight, weigh 30 parts of the base liquid, 10 parts of acrylic acid, 5 parts of carboxymethyl cellulose, 3 parts of N,N'-methylenebisacrylamide, 0.7 1 part of ammonium persulfate, 5 parts of urea, 0.3 part of 2-mercaptoethanol, 3 parts of acetone, 10 parts of absolute ethanol, 50 parts of deionized water, and gelatinize the base liquid at 60°C for 10 minutes to obtain gelatinization Liquid A, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com