Polymer sand-fixation agent

A technology of sand-fixing agent and polymer, applied in the field of sand-fixing, which can solve the problems of poor film-forming property, poor water-retaining effect, and not easy to loose sand and agglomerate, and achieve the effects of improving swelling rate, improving water-retaining effect, and strengthening sand-fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

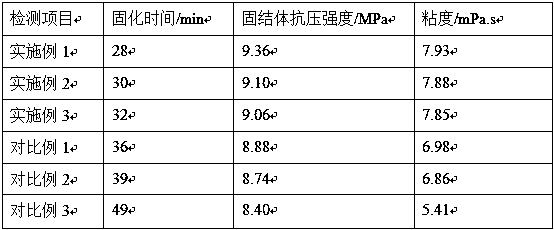

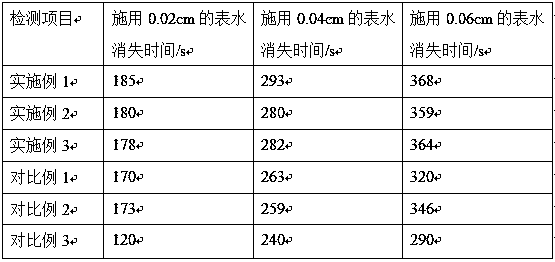

Examples

preparation example Construction

[0032]The preparation method of composite polymer emulsion, comprises the steps:

[0033] (1) Mix 2-amino-4-hydroxy-6-methylpyrimidine and dimethyl sulfoxide in a mortar according to the mass ratio of 7~12:1, and grind at 350~550r / min for 1~3h to obtain the abrasive , take the grinding material and heat-treat it in an oven at 45~65°C for 12~16h to obtain a dry material, take the dry material in a reaction kettle, add hexamethylene diisocyanate with a weight of 8~13% of the dry material to mix, and protect it with nitrogen, and use 400~ 700r / min magnetic stirring for 30~55min, heating up to 60~80°C, cooling down to room temperature naturally to obtain the reaction material, taking the reaction material and adding n-hexane to mix at a mass ratio of 1:3~5, stirring at 500~800r / min for 2~ 4h, get the functional monomer liquid;

[0034] (2) At 30~55°C, take acrylic acid, butyl acrylate, functional monomer liquid, and NaOH solution with a mass fraction of 10~15% according to the ma...

Embodiment 1

[0040] Additive: Mix didecyl sebacate and sodium laureth sulfate at a mass ratio of 3:1 to obtain the additive.

[0041] Initiator: Mix sodium persulfate and azobisisobutyronitrile at a mass ratio of 2:1 to obtain an initiator.

[0042] Rubber material: Mix guar gum and xanthan gum at a mass ratio of 2:1 to obtain the rubber material.

[0043] Reagent A: Mix a 60% triethylamine solution and a 0.1mol / L sodium carbonate solution at a mass ratio of 4:1 to obtain Reagent A.

[0044] Reagent B: Mix calcium chloride solution with a concentration of 0.2 mol / L and glutaraldehyde at a mass ratio of 7:1 to obtain reagent B.

[0045] Auxiliary agent: Mix azobenzene, cyclodextrin, and mercaptoethanol in a mass ratio of 1:3:2 to obtain an auxiliary agent.

[0046] Film-forming agent: in parts by weight, 20 parts of N-methylpyrrolidone, 10 parts of graphene oxide, 6 parts of nitrocellulose with a nitrogen content of 11.2%, 8 parts of 4,4'-dinitrodiphenyl Disemicarbazide was mixed in the ...

Embodiment 2

[0055] Additive: Mix didecyl sebacate and sodium laureth sulfate at a mass ratio of 6:1 to obtain the additive.

[0056] Initiator: Mix sodium persulfate and azobisisobutyronitrile at a mass ratio of 4:1 to obtain an initiator.

[0057] Rubber material: Mix guar gum and xanthan gum at a mass ratio of 5:1 to obtain the rubber material.

[0058] Reagent A: According to the mass ratio of 8:1, take 60% triethylamine solution and 0.1mol / L sodium carbonate solution and mix to obtain reagent A.

[0059] Reagent B: Mix calcium chloride solution with a concentration of 0.2 mol / L and glutaraldehyde at a mass ratio of 10:1 to obtain reagent B.

[0060] Auxiliary: Mix azobenzene, cyclodextrin, and mercaptoethanol at a mass ratio of 1:6:2 to obtain an auxiliary.

[0061] Film-forming agent: in parts by weight, 35 parts of N-methylpyrrolidone, 18 parts of graphene oxide, 10 parts of nitrocellulose with a nitrogen content of 12.5%, 14 parts of 4,4'-dinitrodiphenyl Disemicarbazide was mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com