High-conductivity high-temperature-resisting copper alloy preparing method

A technology of high temperature resistance and copper alloy, applied in the field of high conductivity and high temperature resistance copper alloy preparation, can solve the problems of high softening temperature, low electrical conductivity, reduced electrical conductivity, etc. fine-grained effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

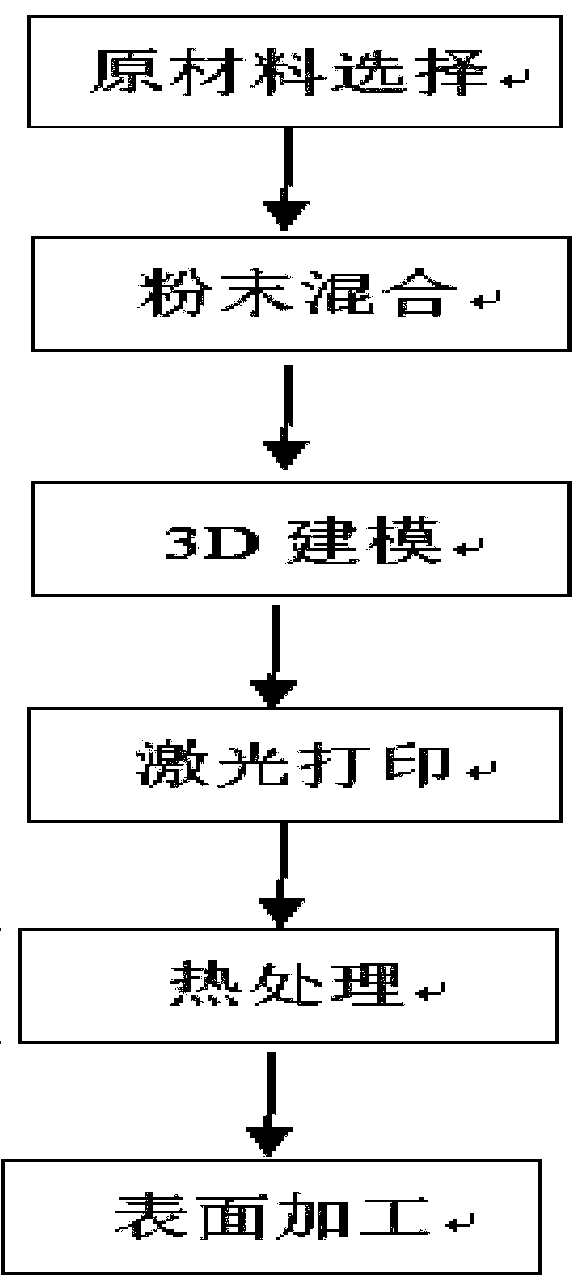

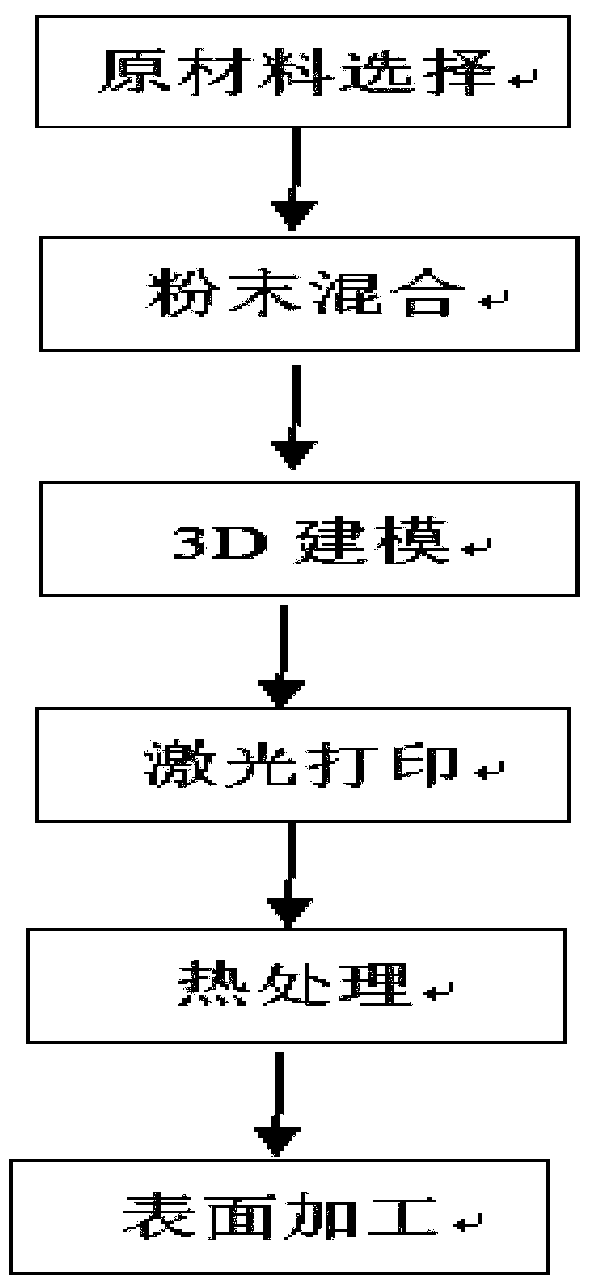

[0031] A method for preparing a high-conductivity and high-temperature-resistant copper alloy mainly includes the following steps:

[0032] (1) Raw material selection

[0033] Weighing 90wt% atomized copper powder and 10wt% WC as raw materials by weight, stand-by, wherein the atomized copper powder particle size is 5 μm, and the WC powder particle size is 0.3 μm. If the particle size is too large or too small, then The specific surface area of the formed atomized copper powder is small or large, which cannot meet the requirements and affects the performance of the prepared copper alloy;

[0034] (2) Powder mixing

[0035] Put the copper powder, WC and AlN powder of the above weight into the atmosphere protection ball mill, the ball to material ratio is 1:2, vacuumize, when the vacuum pressure in the atmosphere protection ball mill is 1Pa, then fill the hydrogen to 0.6Mpa, and then ball mill for 1h;

[0036] (3) 3D modeling

[0037] Use 3D printing software to model accord...

Embodiment 2

[0045] A method for preparing a high-conductivity and high-temperature-resistant copper alloy mainly includes the following steps:

[0046] (1) Raw material selection

[0047] Weigh 95wt% atomized copper powder and 5wt% AlN as raw materials for use, wherein the atomized copper powder particle size is 25 μm, and the AlN powder particle size is 3 μm. If the particle size is too large or too small, it will form The specific surface area of the atomized copper powder is small or large, which cannot meet the requirements and affects the performance of the prepared copper alloy;

[0048] (2) Powder mixing

[0049] Put the copper powder, WC and AlN powder of the above weight into the atmosphere protection ball mill, the ball to material ratio is 1:3, vacuumize, and when the vacuum pressure in the atmosphere protection ball mill is 5Pa, fill it with hydrogen to 0.6Mpa, and then ball mill for 3h;

[0050] (3) 3D modeling

[0051] Use 3D printing software to model according to the ...

Embodiment 3

[0059] A method for preparing a high-conductivity and high-temperature-resistant copper alloy mainly includes the following steps:

[0060] (1) Raw material selection

[0061] Weigh the mixture of 99.5wt% atomized copper powder and 0.5wt% WC and AlN as raw material by weight, and set aside for use, wherein the atomized copper powder has a particle size of 50 μm, and the powder particle size of the WC and AlN mixture is 5 μm. If the diameter is too large or too small, the specific surface area of the formed atomized copper powder is small or large, which cannot meet the requirements and affects the performance of the prepared copper alloy;

[0062] (2) Powder mixing

[0063] Put the above-mentioned weight of copper powder, WC, and AlN powder into the atmosphere-protected ball mill, the ball-to-material ratio is 1:5, vacuumize, and when the vacuum pressure in the atmosphere-protected ball mill is 10Pa, fill it with hydrogen to 0.6Mpa, and then ball mill for 5h;

[0064] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com