A kind of epoxy resin containing sulfone group and its synthetic method

A technology of epoxy resin and synthesis method, which is applied in the field of epoxy resin preparation and achieves the effects of high reaction efficiency, improved threshold value and prolonged storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of synthetic method containing sulfone group epoxy resin, comprises the following steps;

[0040] The raw material allyl glycidyl ether and 1,2-ethanedithiol are put into the reactor according to the molar ratio of 2:1, and benzoin dimethyl ether (accounting for the raw material allyl glycidyl ether and 1,2 -5% of the total mass of ethanedithiol) and 1,4-dioxane (accounting for 50% of the total mass of allyl glycidyl ether and 1,2-ethanedithiol), and at 3000mW / cm 2 Under the conditions of ultraviolet light irradiation and stirring, react in an ice-water bath for 1.0 hour; after the reaction, remove the solvent (1,4-dioxane) in a rotary evaporator to obtain the product;

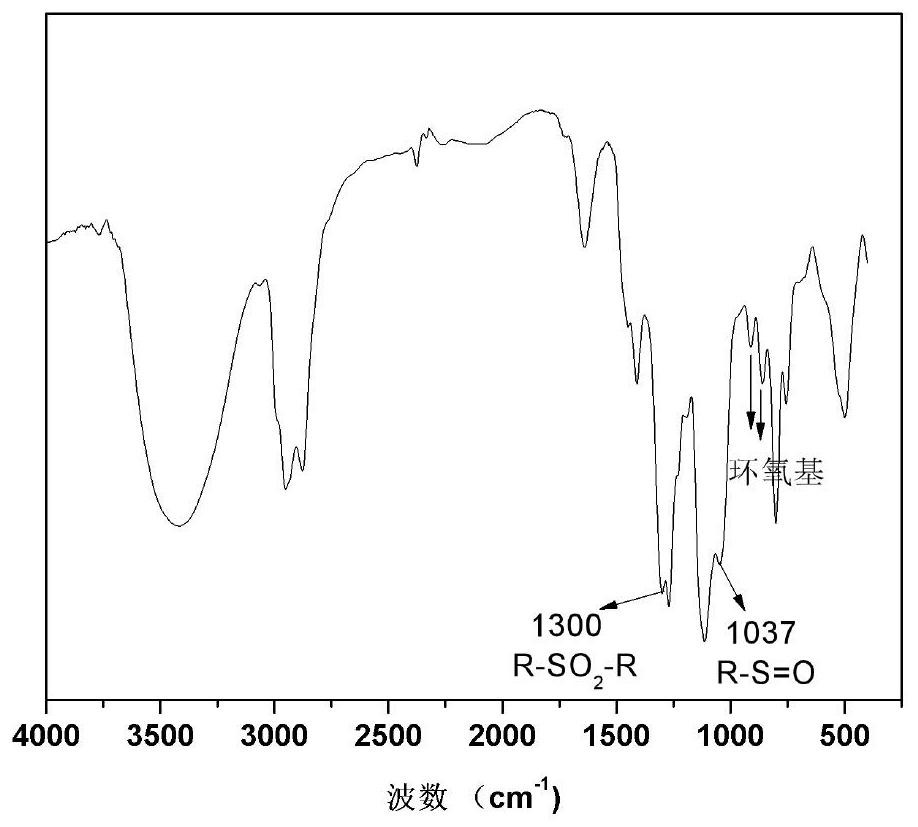

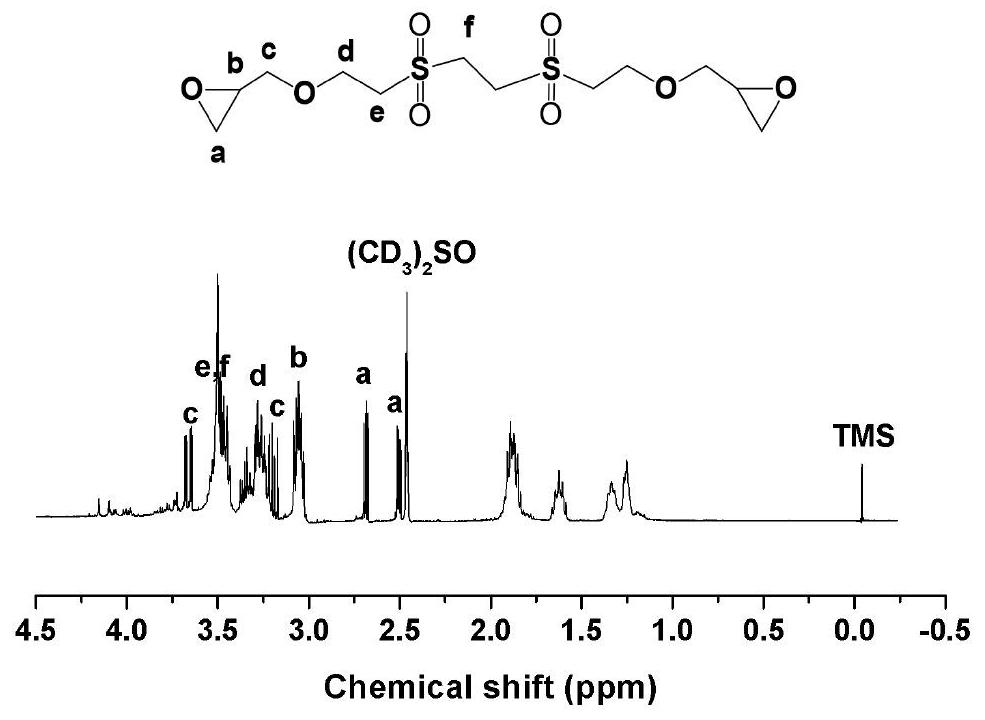

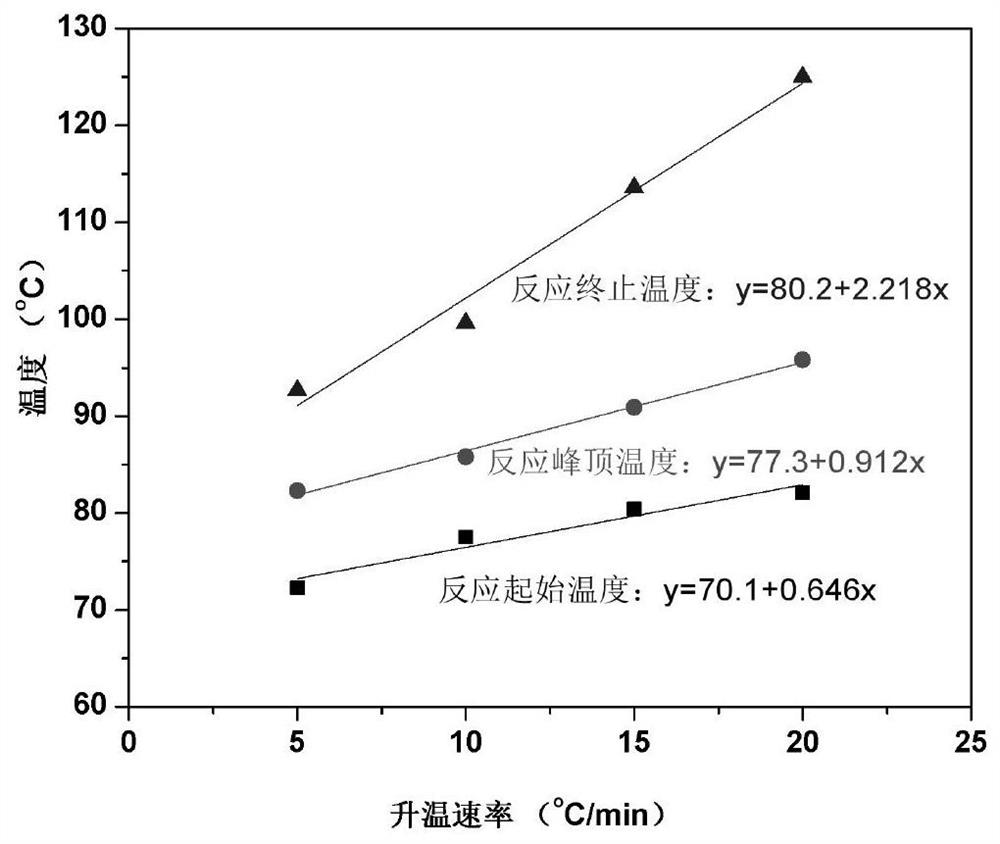

[0041]The obtained product was dissolved in methanol of 10 times its mass, and a concentration of 30% H 2 o 2 (The number of moles of the active ingredient is 3 times the number of moles of the product) and sodium tungstate dihydrate accounting for 1% of the product mass, reacted at room temper...

Embodiment 2

[0055] A kind of synthetic method containing sulfone group epoxy resin, comprises the following steps;

[0056] Put the raw material allyl glycidyl ether and 1,3-propanedithiol in a molar ratio of 2.1:1 into the reactor, and add 2-hydroxy-1-[4-(2-hydroxyethoxy) Phenyl]-2-methyl-1-propanone (accounting for 3% of the total mass of the raw material allyl glycidyl ether and 1,3-propanedithiol) and tetrahydrofuran (accounting for the raw material allyl glycidyl ether and 1, 70% of the total mass of 3-propanedithiol), and at 1500mW / cm 2 Under ultraviolet light irradiation and stirring conditions, react in an ice-water bath for 4.5 hours; after the reaction, remove the solvent (tetrahydrofuran) in a rotary evaporator to obtain the reaction product;

[0057] The obtained product was dissolved in 1,4-dioxane (20 times the mass of the product), added peracetic acid (3 times the molar mass of the product) and magnesium sulfate (3% of the mass of the product), and reacted at room tempera...

Embodiment 3

[0065] A kind of synthetic method containing sulfone group epoxy resin, comprises the following steps;

[0066] The raw material allyl glycidyl ether and 1,5-pentanedithiol are put into the reactor at a molar ratio of 1.9:1, and 2,2-dimethyl-α-hydroxyacetophenone (accounting for the raw material 1% of the total mass of allyl glycidyl ether and 1,5-pentanedithiol) and N,N-dimethylformamide (accounting for 1% of the total mass of raw material glycidyl ether and 1,5-pentanedithiol 80%), and at 1500mW / cm 2 Under the conditions of ultraviolet light irradiation and stirring, react in ice-water bath for 8 hours; after the reaction, remove the solvent in a rotary evaporator to obtain the product;

[0067] The product obtained is dissolved in methyl ethyl ketone (15 times of the product mass), and trifluoroacetic acid (10 times of the product molar number) and zinc chloride (1%-3% of the product mass) are added, at room temperature and reflux temperature After reacting for 3 hours, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com