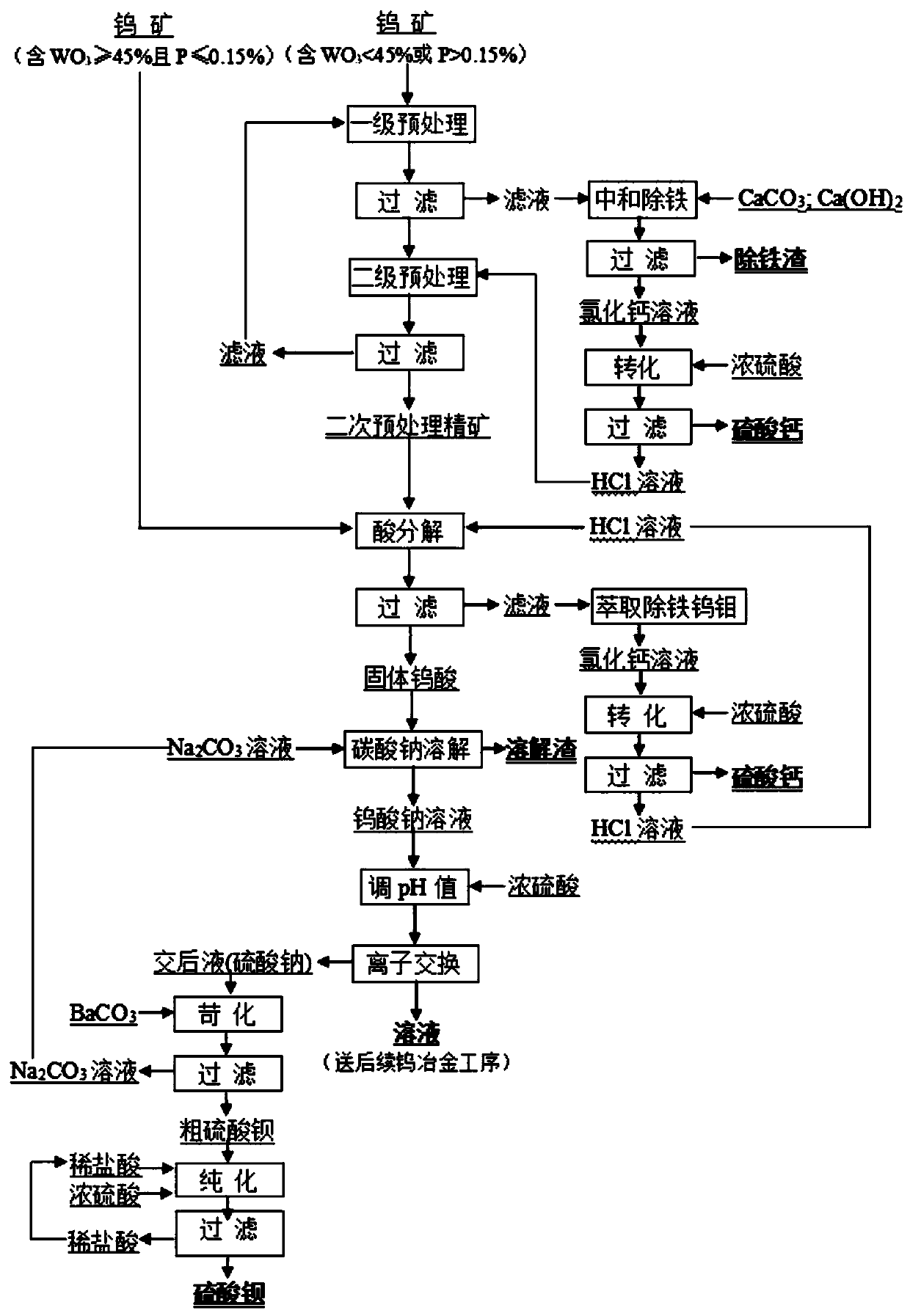

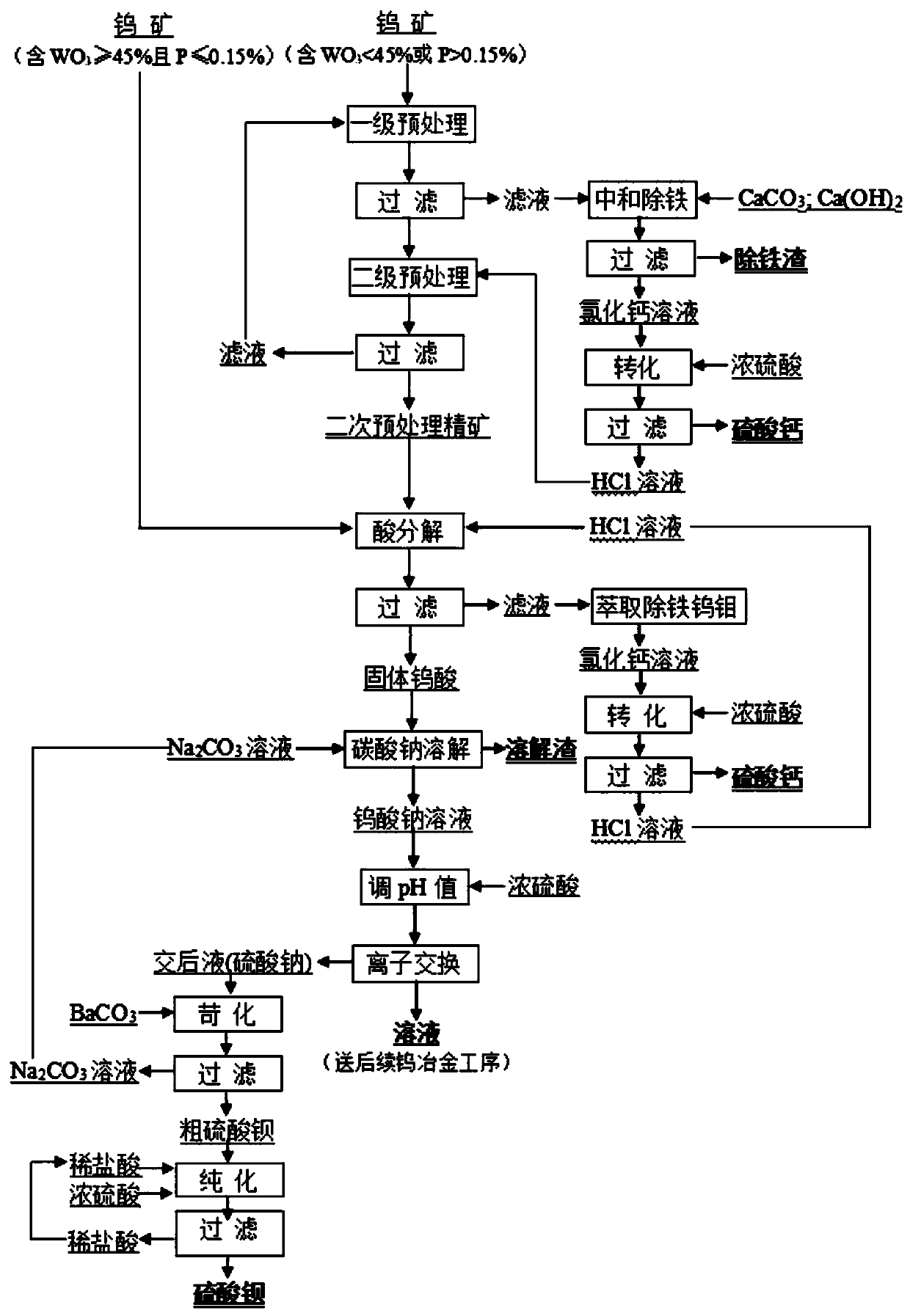

Acid-alkali combination method for extracting tungsten from tungsten minerals

An acid-base combination and mineral technology, applied in the field of hydrometallurgy, can solve the problems of high equipment safety requirements, complicated operation, and high rate of alkali decomposition of slag and slag, so as to ensure the recovery rate and simplify the process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The scheelite used contains WO 3 58%, containing P 0.03%, containing Mo 0.1%, particle size less than 150 microns.

[0060] 1) Acid decomposition:

[0061] Weigh 500g of the above-mentioned scheelite, mix it with 1500mL of hydrochloric acid solution with a concentration of 6.0mol / L, stir and react in a closed glass reactor at 95°C for 2 hours, and slowly add 10mL of H 2 o 2 Solution (H 2 o 2 The mass concentration is 30%), after filtration, solid tungstic acid and acid decomposition mother liquor are obtained, and the obtained tungstic acid contains WO 3 81%, the obtained acid decomposes and contains WO in the mother liquor 3 0.22g / L, Mo 0.06g / L, Ca 54g / L, Fe 0.6g / L, Na 0.08g / L, K 0.05g / L, H + 3.0mol / L. The obtained tungstic acid was washed 4 times with 180mL deionized water each time and collected respectively.

[0062] 2) Conversion and purification of acid decomposition mother liquor:

[0063] Add 87g CaCl while stirring in the acid decomposition mother liqu...

Embodiment 2

[0072] The scheelite used contains WO 3 29%, containing P 1.6%, containing Mo 2.3%, particle size less than 150 microns.

[0073] 1) The first level of preprocessing:

[0074] Take 2000g of the above-mentioned scheelite ore, slowly add 6000mL of hydrochloric acid solution with a concentration of 1.5mol / L and start stirring, then continue to stir at room temperature for 1 hour and then filter. The obtained filter cake is the first-stage pretreatment concentrate, which is used for the second-stage pretreatment, and the obtained filtrate is the first-stage pretreatment mother liquor, wherein, the first-stage pretreatment mother liquor contains WO 3 0.34g / L, Mo 0.1g / L, P 0.6g / L, Ca 19g / L, Fe 0.8g / L, K 0.05g / L, Na 0.08g / L, H + 0.46g / L.

[0075] 2) Purification and conversion of pretreatment mother liquor:

[0076] Get 5000mL of the aforementioned first-stage pretreatment mother liquor, add CaCO thereto while stirring 3 powder until the pH of the solution is 4.0, then continue...

Embodiment 3

[0084] The scheelite that adopts is the second grade pretreatment ore that obtains in step 3) in embodiment 2, wherein contains WO 3 50.8%, containing P 0.12%, containing Mo 3.7%.

[0085] 1) Acid decomposition:

[0086] Weigh 600g of the above-mentioned second-stage pretreatment ore, mix it with 4000mL of hydrochloric acid solution with a concentration of 7.0mol / L, stir and react in a closed glass reactor at 95°C for 3 hours, and slowly add 25mL of H 2 o 2 Solution (H 2 o 2 The mass concentration is 30%), solid tungstic acid and acid decomposition mother liquor are obtained after filtration, and the obtained tungstic acid contains WO 3 77%, the resulting acid decomposition mother liquor contains WO 3 0.63g / L, Mo 4.9g / L, Ca 25g / L, Fe 0.8g / L, Na 0.07g / L, K 0.04g / L, H + 5.6mol / L. The obtained tungstic acid was washed 4 times with 250mL deionized water each time and collected respectively.

[0087] 2) Conversion and purification of acid decomposition mother liquor:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com