Titanium-based tin-antimony-gadolinium oxide cathode material and preparation method thereof

A cathode material, tin-antimony-gadolinium technology, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve problems such as high production costs, poor repeatability, and failure to meet environmental protection requirements, and achieve better quality and lower costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A kind of preparation method of tin antimony gadolinium oxide cathode material, concretely implement according to the following steps:

[0046] Step 1, pretreating the surface of the titanium substrate;

[0047] Step 2, preparing a precursor sol containing tin salt, antimony salt and gadolinium salt, and forming a gel wet film on the surface of the pretreated titanium substrate by dipping and pulling;

[0048] Step 3, drying the gel wet film obtained in step 2 to obtain a gel dry film;

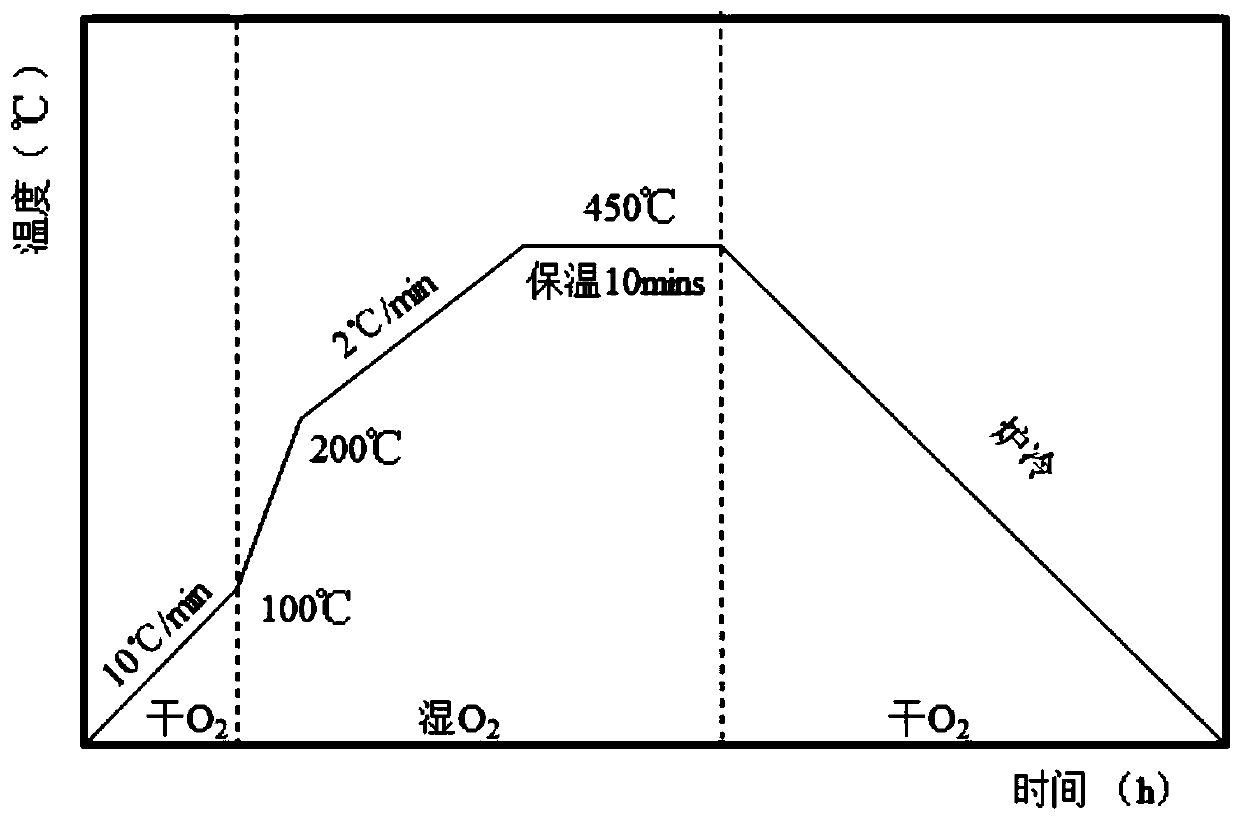

[0049] Step 4, performing crystallization pretreatment on the gel dry film on the surface of the titanium substrate obtained in step 3, until the gel dry film is converted into a tin antimony gadolinium oxide film;

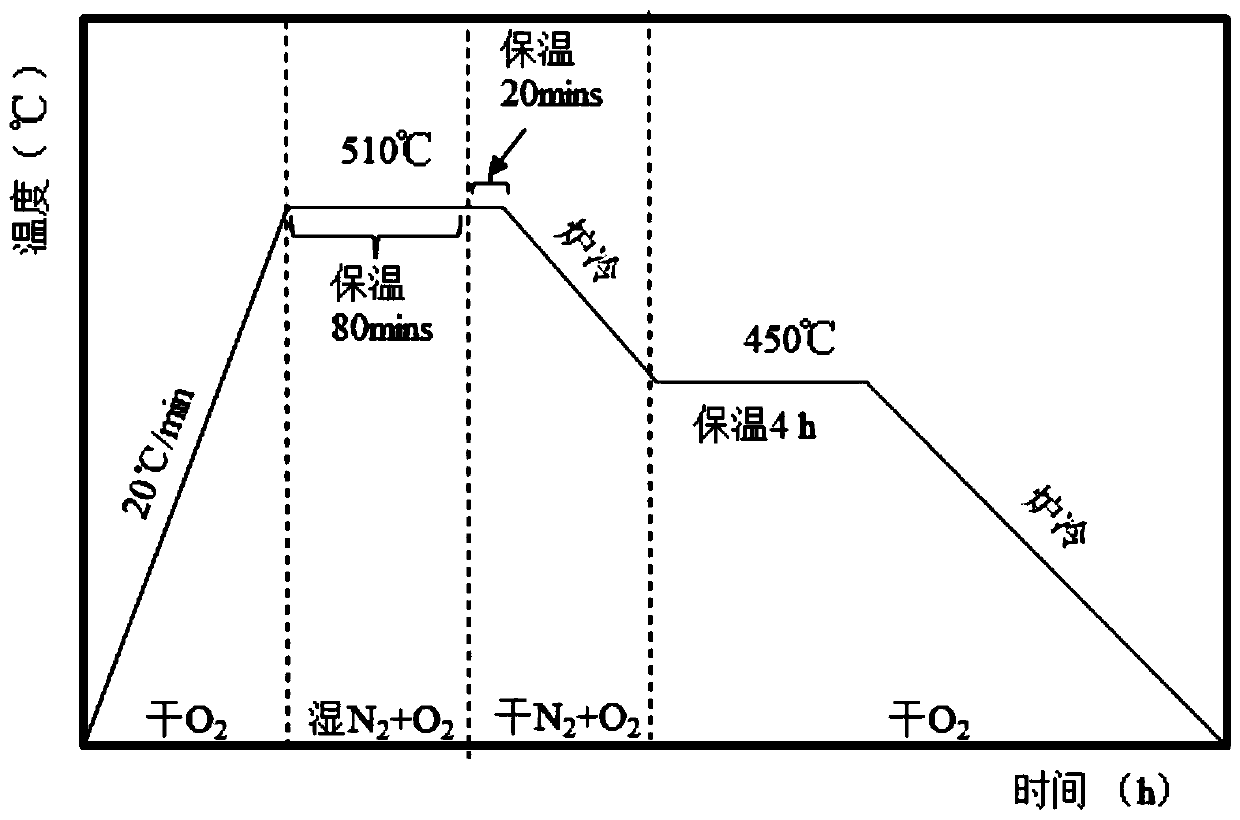

[0050]Step 5, performing crystallization heat treatment on the formed titanium-based tin-antimony-gadolinium oxide thin film to obtain a titanium-based tin-antimony-gadolinium oxide positive electrode material with conductive function.

[0051] The specific steps of step ...

Embodiment 1

[0079] Step 1, pretreating the surface of the titanium substrate;

[0080] Step 1.1. Select a titanium plate as the titanium substrate, polish and polish it with 40, 500 and 1200 mesh sandpaper respectively, and then wash it with acetone and deionized water in turn;

[0081] Step 1.2, put the cleaned titanium substrate into a 40% by mass NaOH solution, soak it at 60°C for 1 hour,

[0082] The titanium substrate soaked in step 1.3 is moved into a boiling oxalic acid solution with a mass percentage of 15% and soaked for 1 hour;

[0083] In step 1.4, the titanium substrate soaked in the oxalic acid solution was ultrasonically cleaned in acetone and deionized water for 5 minutes each, and dried;

[0084] Step 2, preparing a precursor sol containing tin salt, antimony salt and gadolinium salt, and forming a gel wet film on the surface of the pretreated titanium substrate by dipping and pulling;

[0085] Step 2.1, dissolving tin acetate in anhydrous methanol, then adding diethylen...

Embodiment 2

[0100] Step 1, pretreating the surface of the titanium substrate;

[0101] Step 1.1. Select a titanium plate as the titanium substrate, polish and polish it with 40, 500 and 1200 mesh sandpaper respectively, and then wash it with acetone and deionized water in turn;

[0102] Step 1.2, put the cleaned titanium substrate into a 40% by mass NaOH solution, soak it at 70°C for 1.5h,

[0103] The titanium matrix soaked in step 1.3 is moved into a boiling oxalic acid solution with a mass percentage of 15% and soaked for 1.5 hours;

[0104] In step 1.4, the titanium substrate soaked in the oxalic acid solution was ultrasonically cleaned in acetone and deionized water for 7 minutes each, and dried;

[0105] Step 2, preparing a precursor sol containing tin salt, antimony salt and gadolinium salt, and forming a gel wet film on the surface of the pretreated titanium substrate by dipping and pulling;

[0106] Step 2.1, dissolving tin acetate in anhydrous methanol, then adding ethanolamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com