Preparation method of PIM-1@MOFs/polymer composite pervaporation membrane

A PIM-1, pervaporation membrane technology, applied in the field of preparation of PIM-1@MOFs/polymer composite pervaporation membranes, can solve the problems of not agglomerating MOFs, restricting applications, etc., achieving a simple preparation method, increasing separation performance, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

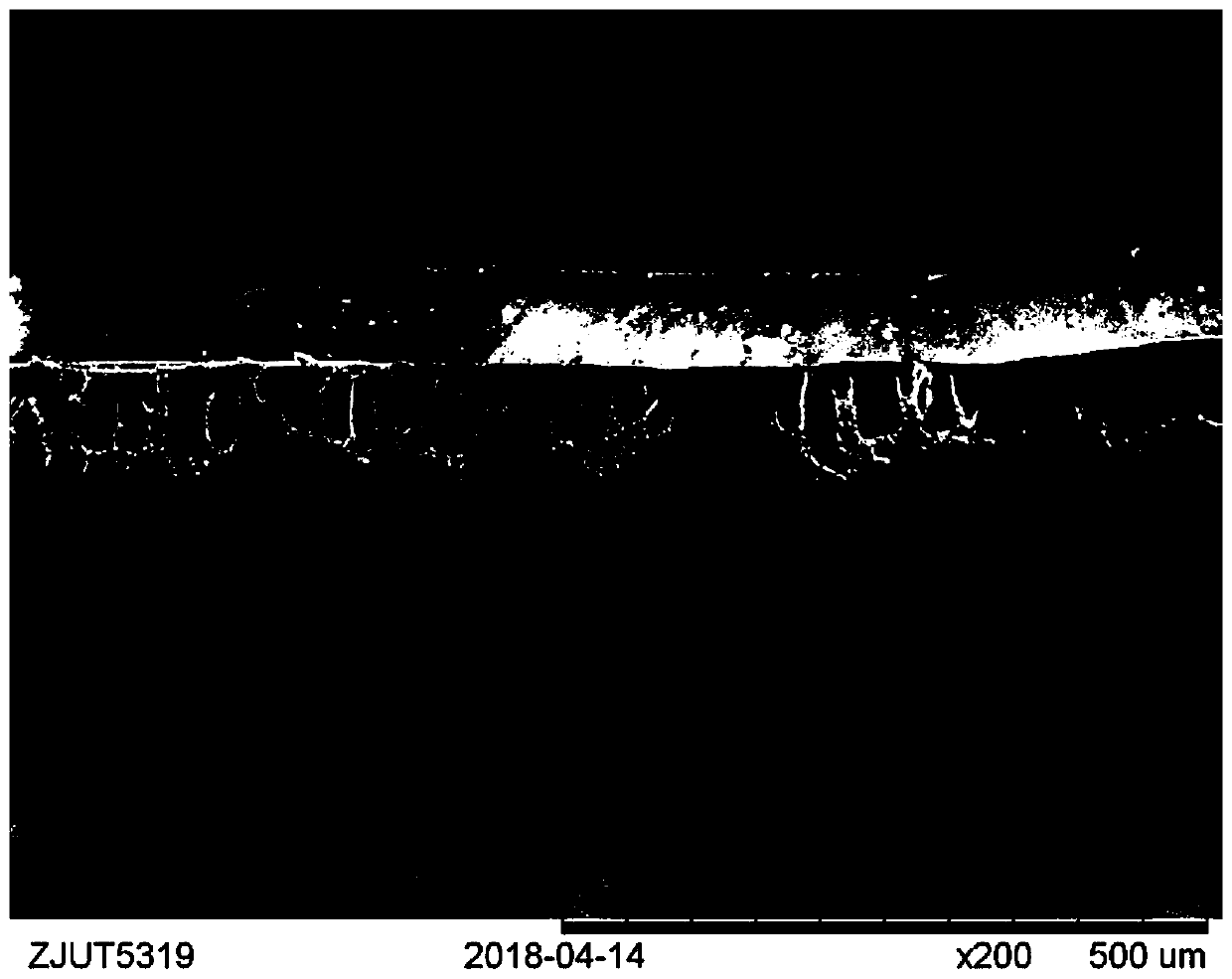

Image

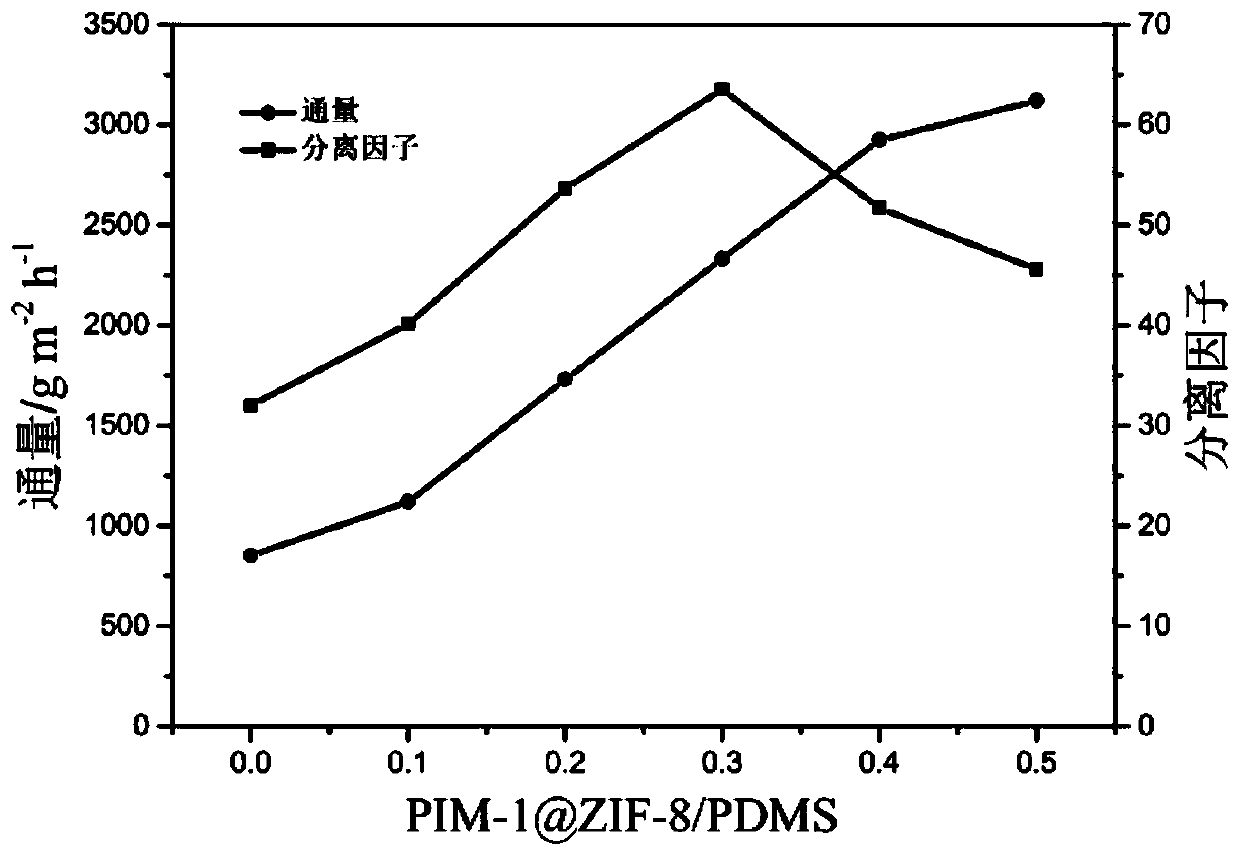

Examples

example 1

[0033](1) Weigh 0.75g of zinc nitrate hexahydrate and 1.65g of 2-methylimidazole and dissolve them in 35mL of methanol respectively, and ultrasonicate for 30min; quickly pour the resulting solution into a 100mL polytetrafluoroethylene reactor, and react at 150°C for 5h, Then cool to room temperature, centrifuge, wash off the white solid surface obtained by the reaction with methanol, which is the ligand of the reaction, wash it three times, centrifuge, and then stir it in methanol at 80°C for 12h, and replace it every 4 hours Methanol was separated by centrifugation, and the resulting solid was vacuum-dried at 80°C for 24 hours.

[0034] (2) Weigh 0.15g of PIM-1 and dissolve it in 5mL of chloroform, and ultrasonicate for 1 hour; weigh 0.0382g of the solid obtained in step 1 and soak in the above solution for 10min, centrifuge to separate ZIF-8, and dry it at room temperature. Wash the soaked ZIF-8 with chloroform for 3 times, then wash with methanol for 3 times, and dry it for...

example 2

[0038] (1) Weigh 0.75g of zinc nitrate hexahydrate and 1.65g of 2-methylimidazole and dissolve them in 35mL of methanol respectively, and ultrasonicate for 30min; quickly pour the resulting solution into a 100mL polytetrafluoroethylene reactor, and react at 150°C for 5h, Then cool to room temperature, centrifuge, wash off the white solid surface obtained by the reaction with methanol, which is the ligand of the reaction, wash it three times, centrifuge, and then stir it in methanol at 80°C for 12h, and replace it every 4 hours Methanol was separated by centrifugation, and the resulting solid was vacuum-dried at 80°C for 24 hours.

[0039] (2) Weigh 0.15g of PIM-1 and dissolve it in 5mL of chloroform, and ultrasonicate for 1 hour; weigh 0.0764g of the solid obtained in step 1 and soak in the above solution for 10min, centrifuge to separate ZIF-8, and dry it at room temperature. Wash the soaked ZIF-8 with chloroform for 3 times, then wash with methanol for 3 times, and dry it fo...

example 3

[0043] (1) Weigh 0.75g of zinc nitrate hexahydrate and 1.65g of 2-methylimidazole and dissolve them in 35mL of methanol respectively, and ultrasonicate for 30min; quickly pour the resulting solution into a 100mL polytetrafluoroethylene reactor, and react at 150°C for 5h, Then cool to room temperature, centrifuge, wash off the white solid surface obtained by the reaction with methanol, which is the ligand of the reaction, wash it three times, centrifuge, and then stir it in methanol at 80°C for 12h, and replace it every 4 hours Methanol was separated by centrifugation, and the resulting solid was vacuum-dried at 80°C for 24 hours.

[0044] (2) Weigh 0.15g of PIM-1 and dissolve it in 5mL of chloroform, and ultrasonicate for 1 hour; weigh 0.0115g of the solid obtained in step 1 and soak in the above solution for 10min, centrifuge to separate ZIF-8, and dry it at room temperature. Wash the soaked ZIF-8 with chloroform for 3 times, then wash with methanol for 3 times, and dry it fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com