Preparation method of sound-absorbing wall cloth

A technology for wall covering and preparation steps, which is applied in the field of preparation of sound-absorbing wall covering, can solve the problems that wall covering fabric does not have sound-absorbing function, secondary pollution, etc., and achieves the effects of enhancing frictional resistance and improving sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

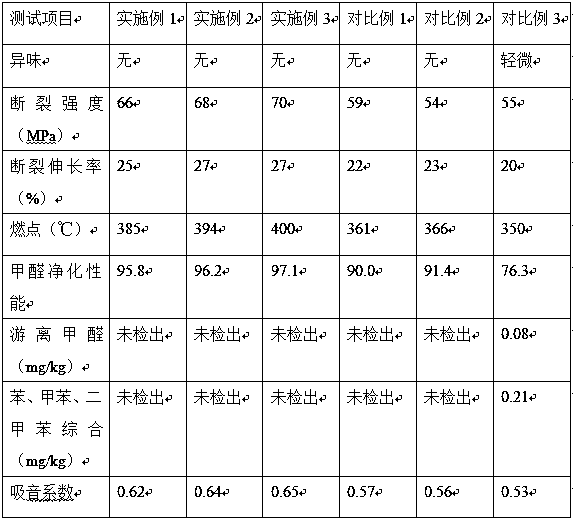

Examples

Embodiment 1

[0029] Preparation of the suspension:

[0030] In terms of parts by weight, the mass of methyl methacrylate and butyl acrylate was mixed to obtain 50 parts of mixed monomers, and 8 parts of ammonium persulfate aqueous solution with a mass fraction of 40% was prepared as an initiator. Add 14 parts of mixed monomers to the four-necked flask, stir for 2 minutes, then add 2 parts of initiator to the four-necked flask, react for 10 minutes, then mix the remaining mixed monomers with the initiator to obtain suspension.

[0031] Preparation of self-crosslinking acrylate emulsion:

[0032] Use a dropping funnel to drop the suspension into the above four-necked flask at a dropping rate of 5mL / min, put the four-necked flask in a water bath, heat up to 85°C, keep the temperature for 40min, and remove the water from the four-necked flask. In a bath, adjust the pH value of the self-crosslinking acrylate emulsion to 7.0 with ammonia water with a mass fraction of 25%, cool naturally to roo...

Embodiment 2

[0042] Preparation of the suspension:

[0043] In terms of parts by weight, the mass of methyl methacrylate and butyl acrylate was mixed to obtain 55 parts of mixed monomers, and 9 parts of ammonium persulfate aqueous solution with a mass fraction of 40% was prepared as an initiator. Add 15 parts of mixed monomers to the four-necked flask, stir for 3 minutes, then add 2 parts of initiator to the four-necked flask, react for 11 minutes, then mix the remaining mixed monomers with the initiator to obtain suspension.

[0044] Preparation of self-crosslinking acrylate emulsion:

[0045] Use a dropping funnel to drop the suspension into the above-mentioned four-necked flask at a dropping rate of 6 mL / min, put the four-necked flask into a water bath, heat up to 87°C, keep the temperature for 43 minutes, and remove the water from the four-necked flask. In a bath, adjust the pH value of the self-crosslinking acrylate emulsion to 7.5 with ammonia water with a mass fraction of 25%. Aft...

Embodiment 3

[0055] Preparation of the suspension:

[0056] In terms of parts by weight, the mass of methyl methacrylate and butyl acrylate was mixed to obtain 60 parts of mixed monomers, and 10 parts of ammonium persulfate aqueous solution with a mass fraction of 40% was prepared as an initiator. Add 16 parts of mixed monomers to the four-necked flask, stir for 4 minutes, then add 3 parts of initiator to the four-necked flask, react for 12 minutes, then mix the remaining mixed monomers with the initiator to obtain suspension.

[0057] Preparation of self-crosslinking acrylate emulsion:

[0058] Use a dropping funnel to drop the suspension into the above four-necked flask at a dropping rate of 7 mL / min, put the four-necked flask in a water bath, heat up to 90°C, keep the temperature for 45 minutes, and remove the water from the four-necked flask. In a bath, adjust the pH value of the self-crosslinking acrylate emulsion to 8.0 with ammonia water with a mass fraction of 25%, cool naturally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com