Preparation method of polyethersulfone chelate membrane chemically grafted with polyamino and polycarboxy functional groups

A chemical grafting and carboxyl functional technology, which is applied in chemical instruments and methods, inorganic chemistry, and other chemical processes, can solve problems such as the application limitations of polyethersulfone ultrafiltration membranes, improve the comprehensive application efficiency of engineering, and facilitate the processing process , the effect of high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

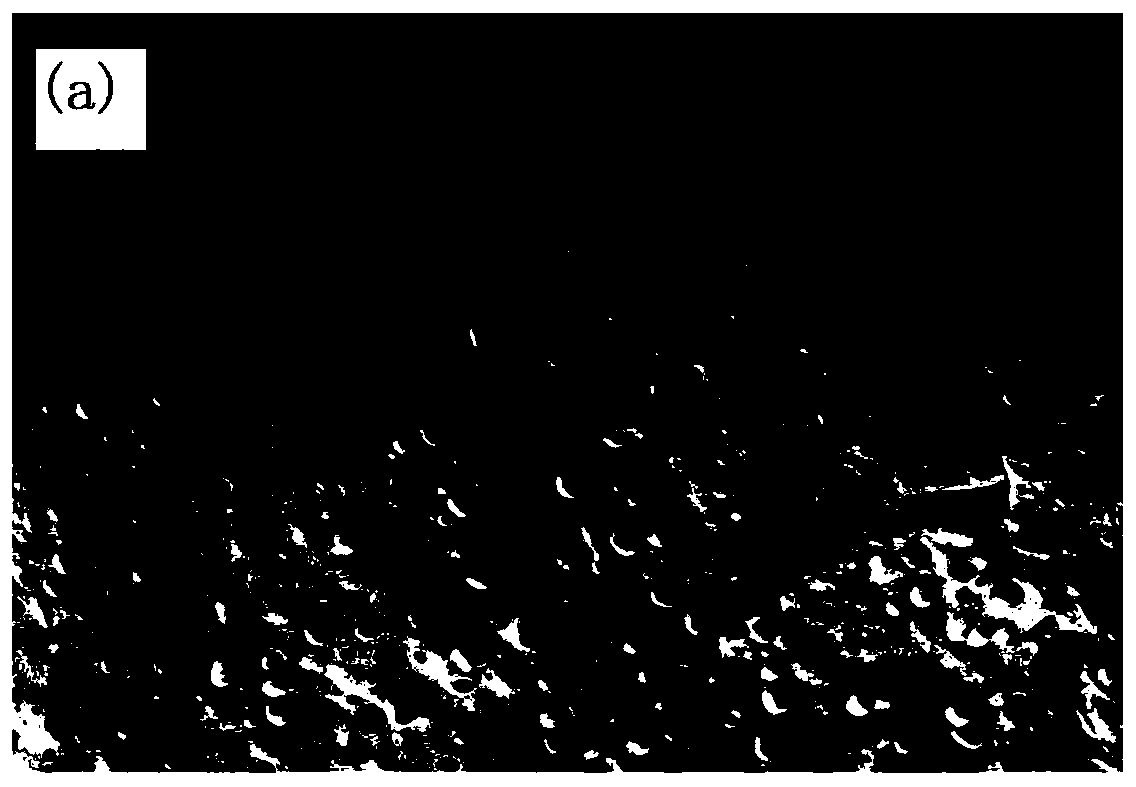

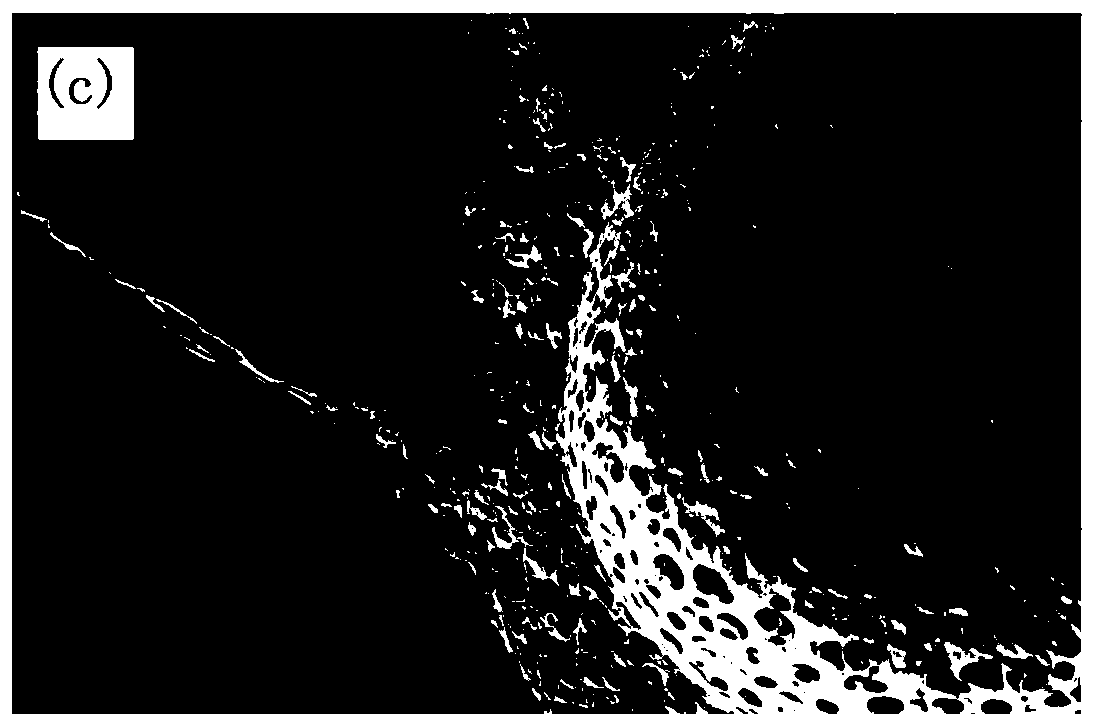

[0039] The invention discloses a preparation method of a modified polyethersulfone chelating membrane with excellent adsorption and disposal efficiency for heavy metal pollutants in the water environment. First, the polyethersulfone powder is subjected to low-temperature plasma treatment to make free radicals on the molecular chain The active point is generated, and then under the action of benzoyl peroxide, it reacts with the double bond in the 4-chloromethylstyrene molecule, and then realizes the chlorination modification of polyethersulfone, and then polyethersulfone The chemical bonding between the chlorine functional group grafted in the molecular chain and the amino group in the reaction product of tetraethylenepentamine and nitrilotriacetic acid makes the polyethersulfone molecular chain grafted with polyamino and polycarboxy functional groups, and finally A functional polyethersulfone chelating membrane loaded with polyamino and polycarboxy functional groups was prepare...

Embodiment 1

[0054] S1. Low-temperature plasma treatment of polyethersulfone powder:

[0055] Place 6g of polyethersulfone powder on the loading plate in the reaction chamber of the plasma processor after being wrapped with a gauze bag, close the feed port of the reaction chamber, then open the vacuum port of the plasma processor and close the air inlet and outlet of the plasma processor. At the gas port, start the vacuum pump until the reading of the vacuum gauge on the plasma processor is -0.1Mpa; then close the vacuum port and the vacuum pump, open the valve of the argon cylinder and the air inlet, and feed argon, and control the flow of argon to 30mL / min , when the reading of the vacuum gauge returns to 0MPa, open the gas outlet of the reaction chamber, and then turn on the high-frequency power supply of the low-temperature plasma processor to irradiate the polyethersulfone powder. The plasma power is controlled at 30W, and the irradiation treatment temperature is room temperature. The...

Embodiment 2

[0070] S1. Low-temperature plasma treatment of polyethersulfone powder:

[0071] Place 6g of polyethersulfone powder on the loading plate in the reaction chamber of the plasma processor after being wrapped with a gauze bag, close the feed port of the reaction chamber, then open the vacuum port of the plasma processor and close the air inlet and outlet of the plasma processor. At the gas port, start the vacuum pump until the reading of the vacuum gauge on the plasma processor is -0.1Mpa; then close the vacuum port and the vacuum pump, open the valve of the argon cylinder and the air inlet, and feed argon, and control the flow of argon to 30mL / min , when the reading of the vacuum gauge returns to 0MPa, open the gas outlet of the reaction chamber, and then turn on the high-frequency power supply of the low-temperature plasma processor to irradiate the polyethersulfone powder. The plasma power is controlled at 30W, and the irradiation treatment temperature is room temperature. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com