TPV (Thermoplastic vulcanizate) material as well as preparation method and application method thereof

A raw material, mineral oil technology, applied in the field of polymers, can solve the problems of not being able to apply the corner material of automobile sealing strips, insufficient bonding degree, and low strength, etc., and achieve good adhesion, comprehensive vulcanization, and increased crosslinking degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

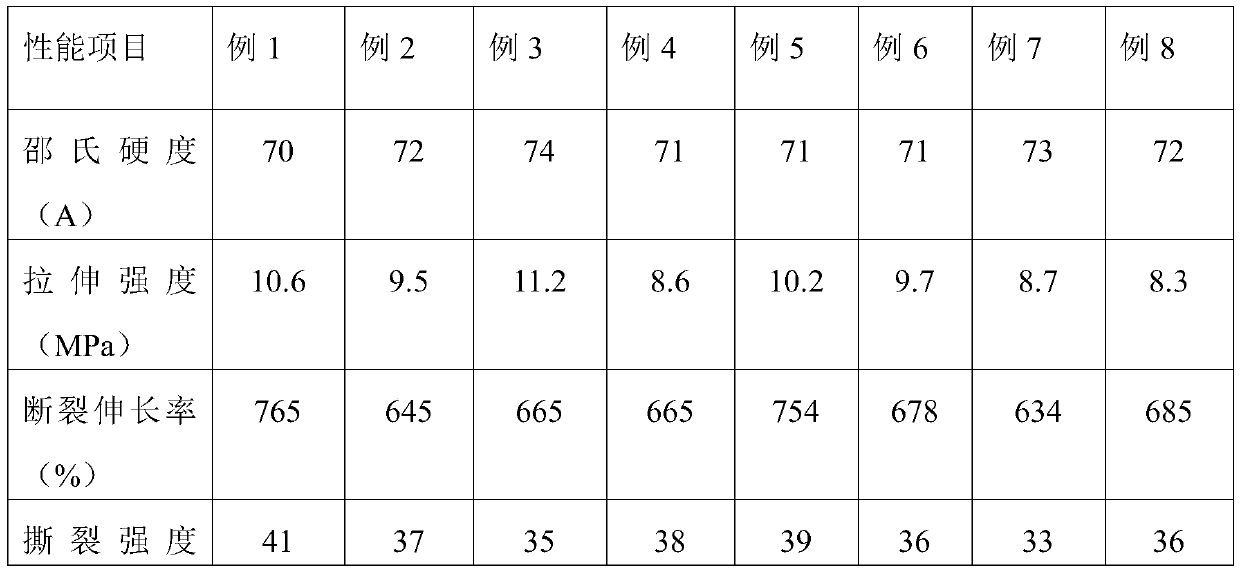

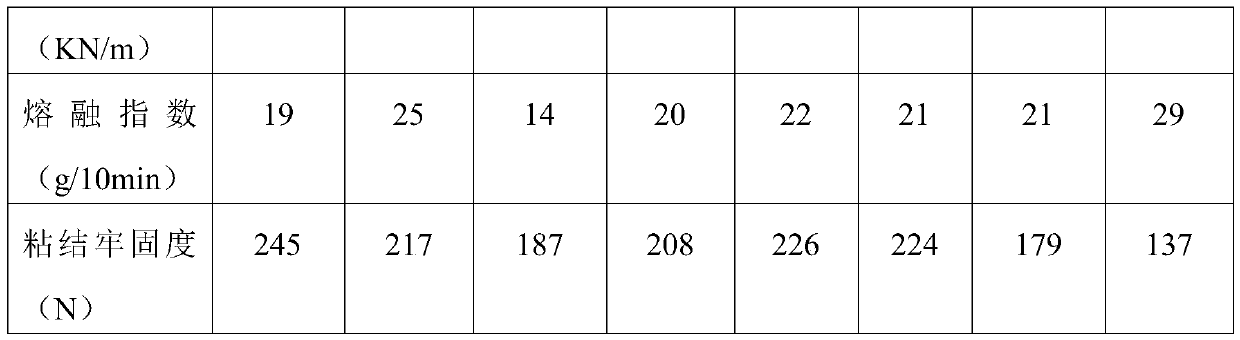

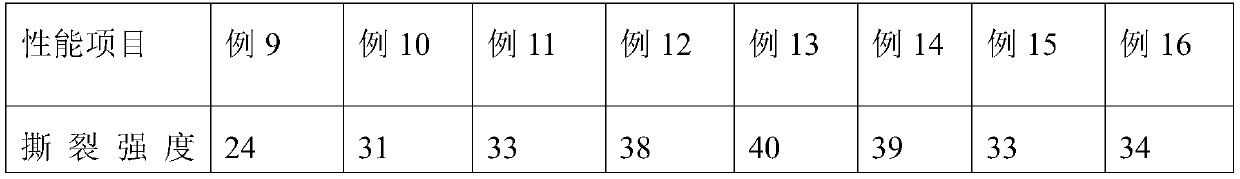

Examples

Embodiment 1

[0040] A kind of TPV material is prepared by liquid cross-linking and graft vulcanization process, and the raw material of described TPV material is counted as: 100 parts of RE-EPDM elastomer; 100 parts of ultra-high viscosity mineral oil; 10 parts of olefinic acid compound Modified EPDM; 20 parts of acrylic acid grafted POE; 15 parts of polypropylene; 5 parts of reactive octyl phenolic resin (the first crosslinking agent); 3.5 parts of stannous chloride; 0.5 parts of dicumyl peroxide (the second crosslinking agent); 0.3 parts wollastonite.

[0041] Among them, the RE-EPDM has extremely low shear thinning properties, and its viscosity ranges from 80000 Pascal-seconds (pa-s) at 0.15 rad / s to 1000 Pascal-seconds (pa-s) at 220 rad / s, so The 100°C kinematic viscosity of the above ultra-high viscosity mineral oil is greater than 30mm 2 / s, the flash point is greater than 280°C, the content of dimethyl sulfoxide is less than 3%, and the content of linear hydrocarbons accounts for a...

Embodiment 2

[0057] The raw material of a kind of TPV material is counted as follows by weight: 100 parts of RE-EPDM elastomers; 150 parts of ultra-high viscosity mineral oils; 5 parts of olefinic acid compounds modified EPDM; 25 parts of acrylic acid grafted POE; 20 parts of polypropylene; Parts of phenolic resin (first crosslinking agent); 4.5 parts of zincous chloride; 1 part of benzoyl peroxide (BPO) (second crosslinking agent); 0.5 parts of calcium carbonate.

[0058] Wherein, the modified EPDM of the alkenoic acid compound comprises the steps of: dissolving 100 parts of EPDM and 10 parts of acrylic acid in a mixed organic solvent of n-heptane / cyclohexanone three times the mass, and then adding 5 parts of dissolved BPO to initiate Add the cyclohexanone of the agent, feed nitrogen gas and react for 16 hours, add excess ethanol under the condition of stirring to precipitate the product, and dry the precipitate to constant weight to obtain the enoic acid compound modified EPDM.

[0059] ...

Embodiment 3

[0070] The raw material of a kind of TPV material is calculated by weight: 100 parts of RE-EPDM elastomers; 50 parts of ultra-high viscosity mineral oils; 15 parts of olefinic acid compounds modified EPDM; 15 parts of acrylic acid grafted POE; 10 parts of polypropylene; 1 part of brominated phenolic resin (first cross-linking agent); 1 part of stannous chloride; 0.1 part of 1,3-bis(tert-butylperoxyisopropyl)benzene (second cross-linking agent); 0.1 part of talcum powder.

[0071]Wherein, the modified EPDM of the alkenoic acid compound comprises the steps of: dissolving 100 parts of EPDM and 2 parts of acrylic acid in a mixed organic solvent of n-heptane / cyclohexanone with three times the mass, and then adding 1 part of dissolved BPO to trigger Add the cyclohexanone of the agent, feed nitrogen gas and react for 16 hours, add excess ethanol under the condition of stirring to precipitate the product, and dry the precipitate to constant weight to obtain the enoic acid compound modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com