Preparation method of ferroferric oxide/silicon dioxide composite fiber wave-absorbing material

A technology of ferroferric oxide and composite fiber, which is applied in the direction of inorganic raw material artificial filaments, etc., can solve the problems of poor particle dispersion, high relative density, narrow absorption frequency band, etc., achieve low density, increase absorbing intensity, and broaden absorption bandwidth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

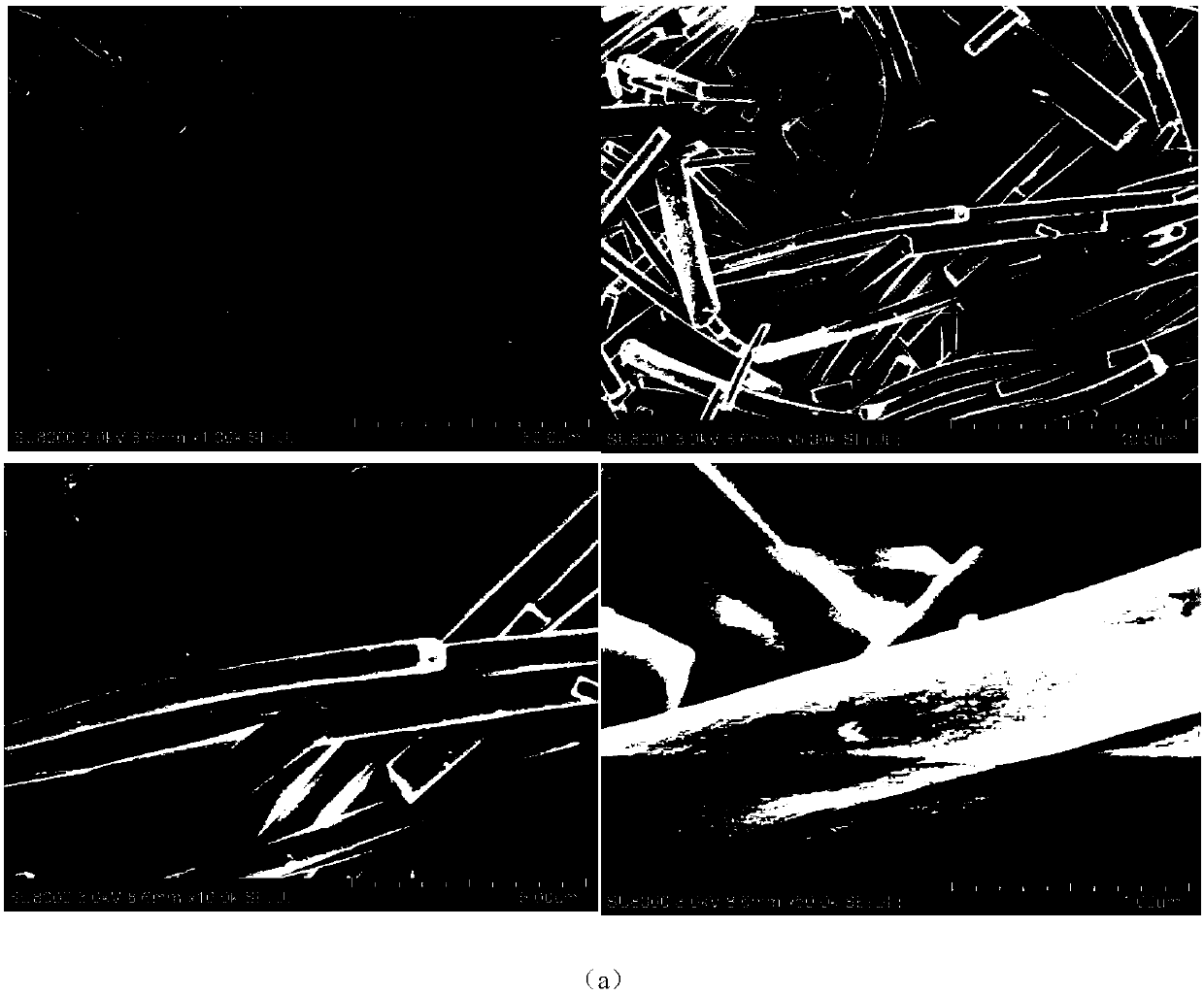

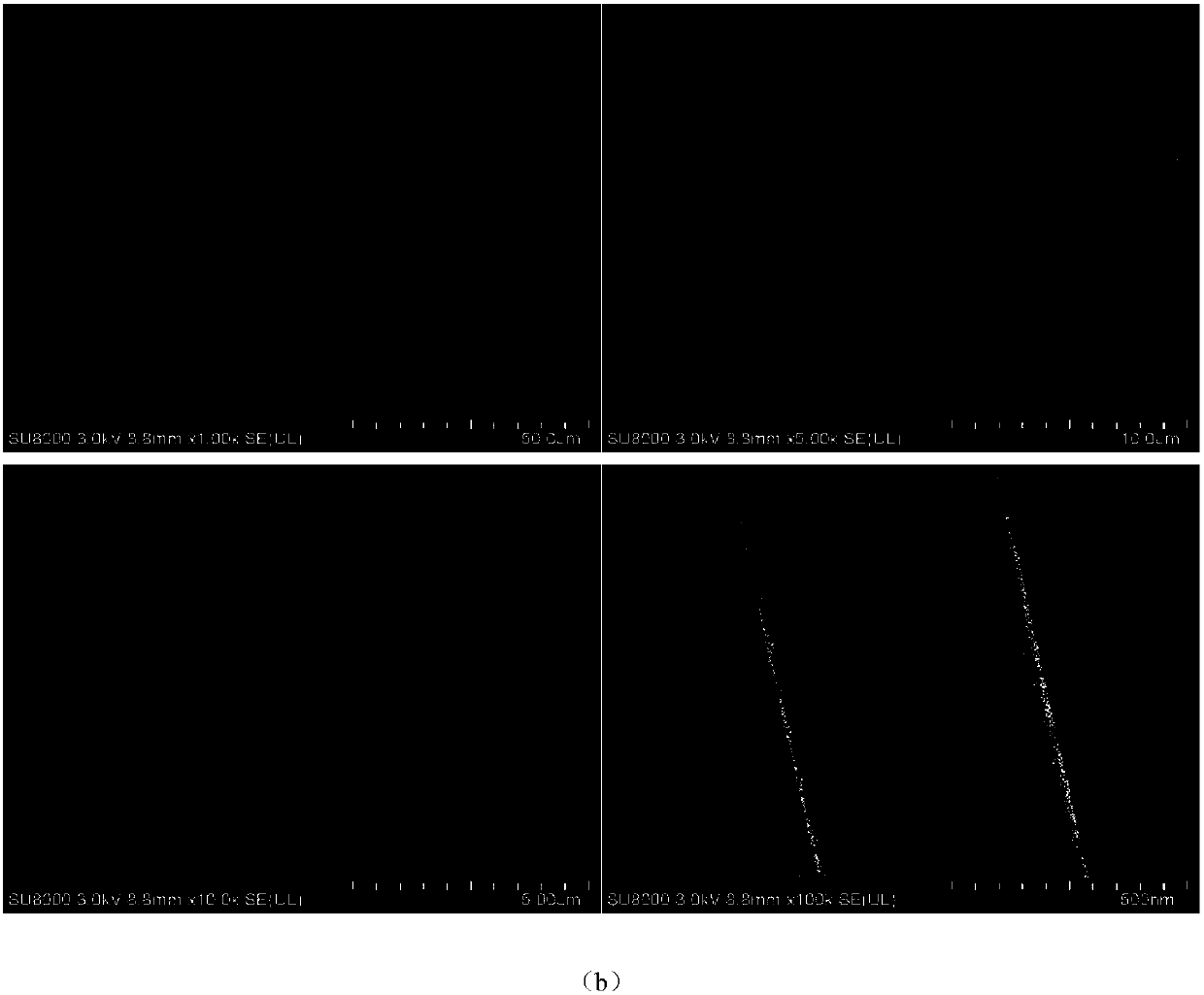

Image

Examples

Embodiment 1

[0033] (1) Get 15g of citric acid, 12.12g of ferric nitrate hexahydrate and 4.17g of ferrous sulfate in a 100mL beaker, add 30mL of deionized water and 45mL of absolute ethanol, place it on a magnetic stirrer and stir for 1 hour, After the mixed solution is completely dissolved, the mixed solution is placed on a constant temperature heating magnetic stirrer and stirred and heated until the remaining volume is 1 / 3 of the original volume, thereby obtaining Fe 3 o 4 Sol.

[0034] (2) Put 200g of tetraethyl orthosilicate in the round bottom flask, then add 150g of ethanol and 30mL of deionized water respectively, after fully mixing, add an appropriate amount of hydrochloric acid to adjust the pH value of the solution to 5, and install a reflux tube After heating and stirring for 5 hours in a constant temperature magnetic stirrer at 50°C, a uniform SiO 2 Sol.

[0035] (3) the Fe made in (1) 3 o 4 The sol and the SiO2 sol made in (2) were uniformly mixed at a mass ratio of 1:1,...

Embodiment 2

[0041] (1) Get 15g of citric acid, 12.12g of ferric nitrate hexahydrate and 4.17g of ferrous sulfate in a 100mL beaker, add 30mL of deionized water and 45mL of absolute ethanol, place it on a magnetic stirrer and stir for 1 hour, After the mixed solution is completely dissolved, the mixed solution is placed on a constant temperature heating magnetic stirrer and stirred and heated until the remaining volume is 1 / 3 of the original volume, thereby obtaining Fe 3 o 4 Sol.

[0042] (2) Put 200g of tetraethyl orthosilicate in the round bottom flask, then add 150g of ethanol and 30mL of deionized water respectively, after fully mixing, add an appropriate amount of hydrochloric acid to adjust the pH value of the solution to 5, and install a reflux tube After heating and stirring for 5 hours in a constant temperature magnetic stirrer at 50°C, a uniform SiO 2 Sol.

[0043] (3) the Fe made in (1) 3 o 4 Sol and SiO made in (2) 2 The sol was evenly mixed at a mass ratio of 1:1, dilut...

Embodiment 3

[0049] (1) Get 15g of citric acid, 12.12g of ferric nitrate hexahydrate and 4.17g of ferrous sulfate in a 100mL beaker, add 30mL of deionized water and 45mL of absolute ethanol, place it on a magnetic stirrer and stir for 1 hour, After the mixed solution is completely dissolved, the mixed solution is placed on a constant temperature heating magnetic stirrer and stirred and heated until the remaining volume is 1 / 3 of the original volume, thereby obtaining Fe 3 o 4 Sol.

[0050] (2) Put 200g of tetraethyl orthosilicate in the round bottom flask, then add 150g of ethanol and 30mL of deionized water respectively, after fully mixing, add an appropriate amount of hydrochloric acid to adjust the pH value of the solution to 5, and install a reflux tube After heating and stirring for 5 hours in a constant temperature magnetic stirrer at 50°C, a uniform SiO 2 Sol.

[0051] (3) the Fe made in (1) 3 o 4 Sol and SiO made in (2) 2 The sol was uniformly mixed at a mass ratio of 2:1, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com