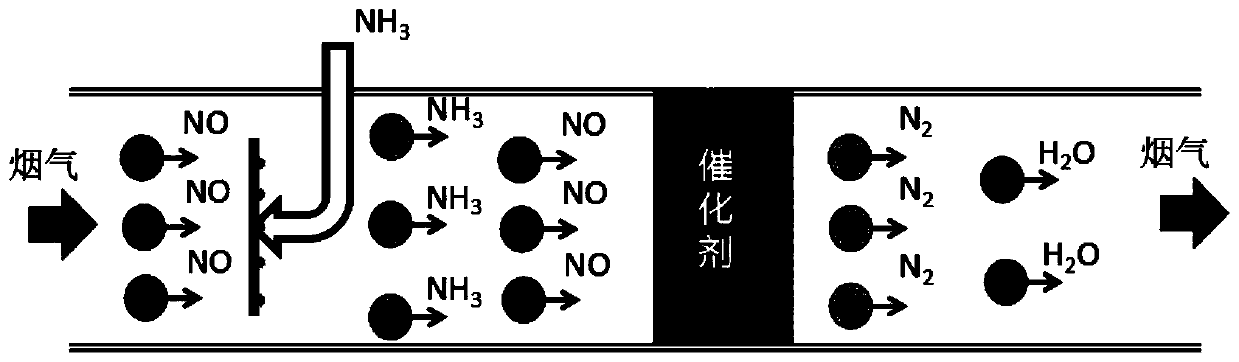

Method for preparing SCR denitration catalyst at low temperatures

A technology of denitrification catalyst and low-temperature conditions, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unproven catalytic activity, low denitrification efficiency, and unstable catalytic activity, etc., to achieve Good application prospect, low cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of molecular sieve carrier: first weigh 0.5mol 86g of titanium tetramethoxide (172) (titanium source) and dissolve it in absolute ethanol, stir it with a magnetic stirrer to mix it evenly, and adjust the pH of the aqueous solution of acetic acid to be 2, Then add 0.0263mol (10.08g) of yttrium nitrate hexahydrate (383.06) (precursor of rare earth metal) and 10g porogen (polyoxyethylene leaf amine) and stir (react at 60°C for 8h) to form a sol, evaporate ethanol and dry, 500 Roasting 12h obtains molecular sieve carrier TiO2-Y2O3, and the particle diameter of molecular sieve carrier is 0.2mm;

[0032] (2) Active component impregnation process: impregnate the molecular sieve carrier TiO2-Y2O3 (2h) with an aqueous solution of 1mol / L vanadic acid, and dry at room temperature to obtain a molecular sieve catalyst impregnated with vanadic acid;

[0033] (3) Roasting and oxidation process: put the impregnated molecular sieve catalyst in a muffle furnace and roast ...

Embodiment 2

[0035] (1) Preparation of molecular sieve carrier: first weigh 0.5mol 114g of tetraethoxytitanium (228) (titanium source) and dissolve it in absolute ethanol, stir it with a magnetic stirrer to mix it evenly, and adjust the pH with the aqueous solution of propionic acid After adding 0.01547mol (4.408g) of Sc(NO3)3·3H2O(285) (precursor of rare earth metal) and 10g of porogen (polyoxyethylene soybean amine) and stirring (reaction at 75°C for 5h) to form a sol, Dry after evaporating ethanol, and roast at 650°C for 10 hours to obtain molecular sieve carrier TiO2-Sc2O3, the particle size of molecular sieve is 0.6mm;

[0036] (2) Active component impregnation process: repeatedly impregnate the molecular sieve carrier TiO2-Sc2O3 (6h) with an aqueous solution of 1mol / L FeVO4, and dry at room temperature to obtain a molecular sieve catalyst impregnated with FeVO4;

[0037] (3) Roasting and oxidation process: put the impregnated molecular sieve catalyst in a muffle furnace and roast at ...

Embodiment 3

[0039] (1) Preparation of molecular sieve carrier: first weigh 0.5mol 170.2g of tetrapropoxytitanium (284.22) (titanium source) and dissolve it in absolute ethanol, stir it with a magnetic stirrer to mix it evenly, adjust the aqueous solution of propionic acid When the pH is 2, add 0.0005mol (0.2165) of La(NO3)·6H2O(433) (precursor of rare earth metal) and 10g of porogen (polyoxyethylene tallow amine) and stir (90°C for 2h) to form a sol, evaporate Dried with ethanol, roasted at 800°C for 8 hours to obtain molecular sieve carrier TiO2-La2O3, molecular sieve particle size is 1.0mm;

[0040] (4) Active component impregnation process: repeatedly impregnate the molecular sieve carrier TiO2-La2O3 (8h) with an aqueous solution of 1mol / L Mn(NO3)2, and dry at room temperature to obtain a molecular sieve catalyst impregnated with Mn(NO3)2;

[0041] (2) Roasting and oxidation process: put the impregnated molecular sieve catalyst in a muffle furnace and roast at 500°C to obtain the SCR d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com