Catalyst for producing methyl methacrylate by one-step oxidative esterification method and its preparation method and application

A technology of methyl methacrylate and oxidative esterification, applied in the field of catalysis, can solve the problems of many by-products, unsuitable regeneration, gap in catalytic activity, etc., and achieves the effects of mild reaction conditions, simple preparation process and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

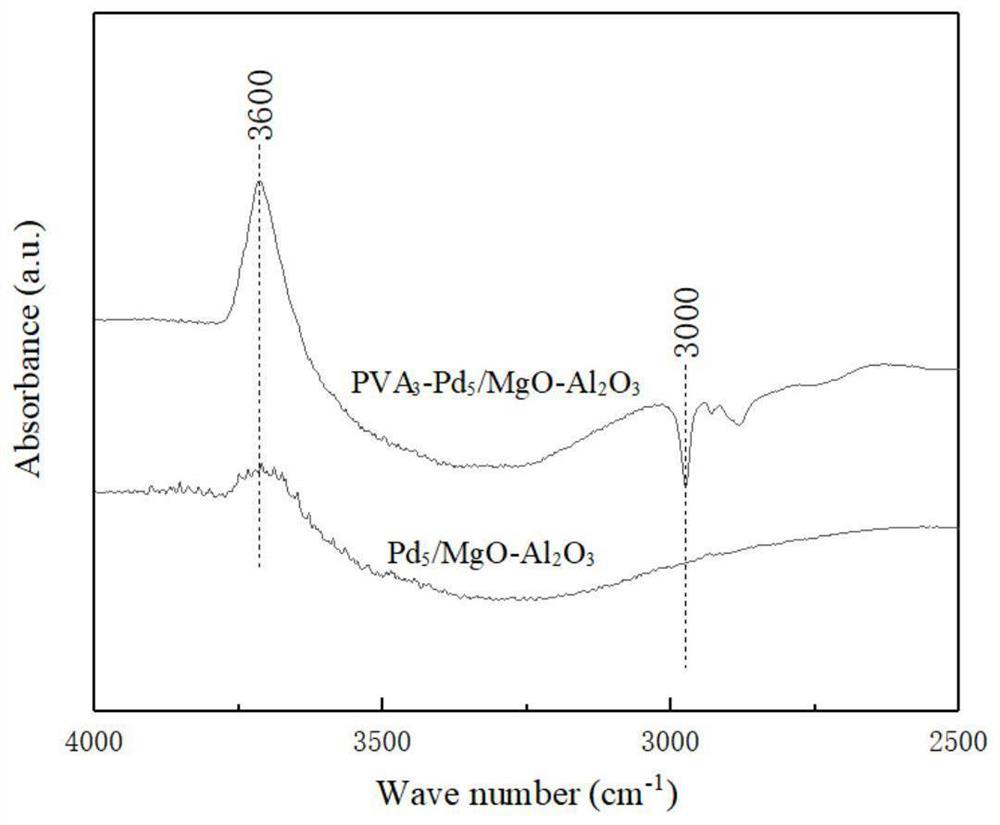

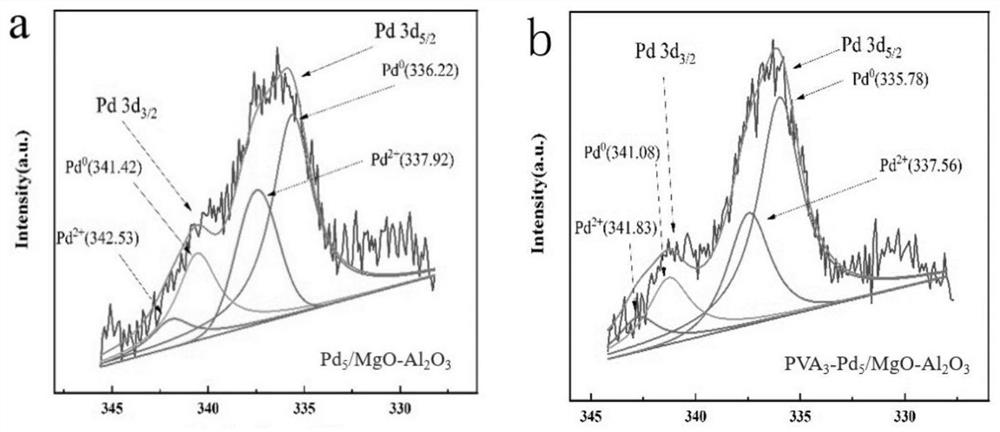

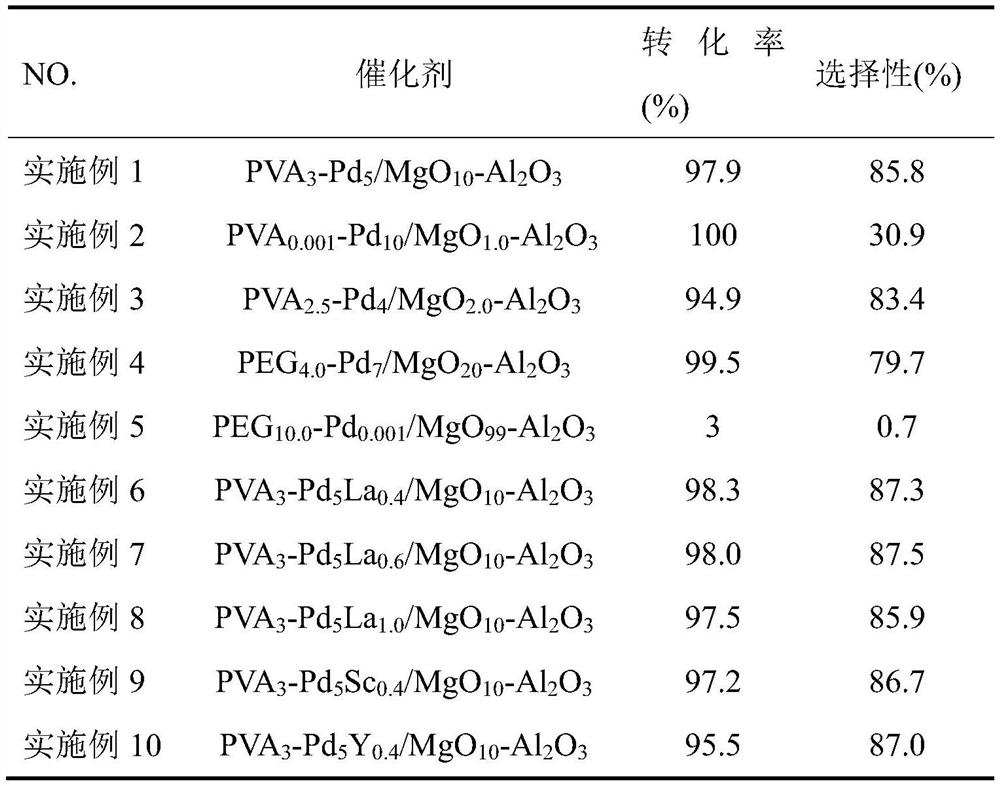

[0024] Example 1 PVA 3 -Pd 5 / MgO 10 -Al 2 o 3 catalyst

[0025] PVA 3 -Pd 5 / MgO 10 -Al 2 o 3 The preparation method of catalyst is as follows:

[0026] (1) 6.4gMg(NO 3 ) 2 ·6H 2 Dissolve O in 200ml deionized water, add carrier 10gγ-Al 2 o 3 , heat and stir until the solvent is evaporated to dryness, dry the obtained solid and grind it into a powder, roast the obtained powder in a nitrogen atmosphere at 350°C to 550°C for 2h to 5h, and then lower it to room temperature to obtain a composite carrier MgO 10 -Al 2 o 3 ;

[0027] (2) Take 0.225g PVA and 0.125g PdCl 2 Dissolve in 9ml deionized water, then add 0.0825g NaCl, stir magnetically at room temperature until completely dissolved, then add 1.5g of MgO prepared in step (1) 10 -Al 2 o 3 Carrier, then stir the resulting mixture and add 10ml of 5wt% NaOH-5wt% HCHO solution for reduction reaction, the reduction reaction temperature is 60°C, and the reduction time is 15min; after the reduction reaction is com...

Embodiment 2

[0029] Example 2 PVA 0.001 -Pd 10 / MgO 1.0 -Al 2 o 3 catalyst

[0030] The preparation method of catalyst adopts the same step as Example 1, and the difference is that the Mg(NO 3 ) 2 ·6H 2 The quality of O is changed to 0.64g, the quality of PVA is changed to 0.00015g, PdCl 2 The quality of NaCl is changed to 0.25g, the quality of NaCl is changed to 0.165g, the consumption of reducing agent 5wt%NaOH-5wt%HCHO is changed to 20ml, and other conditions are the same.

Embodiment 3

[0031] Example 3 PVA 2.5 -Pd 4 / MgO 2.0 -Al 2 o 3 catalyst

[0032] The preparation method of catalyst adopts the same step as Example 1, and the difference is that the Mg(NO 3 ) 2 ·6H 2 The quality of O is changed to 1.28g, the quality of PVA is changed to 0.15g, PdCl 2 The quality of NaCl was changed to 0.1g, the quality of NaCl was changed to 0.066g, the consumption of reducing agent 5wt%NaOH-5wt%HCHO was changed to 8ml, and other conditions were the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com