Preparation method of ternary copper-based sulfide semiconductor semiconductor nanomaterial

A technology of nano-materials and sulfides, applied in chemical instruments and methods, antimony compounds, inorganic chemistry, etc., can solve the problems of uncontrollable preparation process, difficult multi-phase coexistence, poor production stability, etc., to overcome long-term high-temperature treatment , Good production stability and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

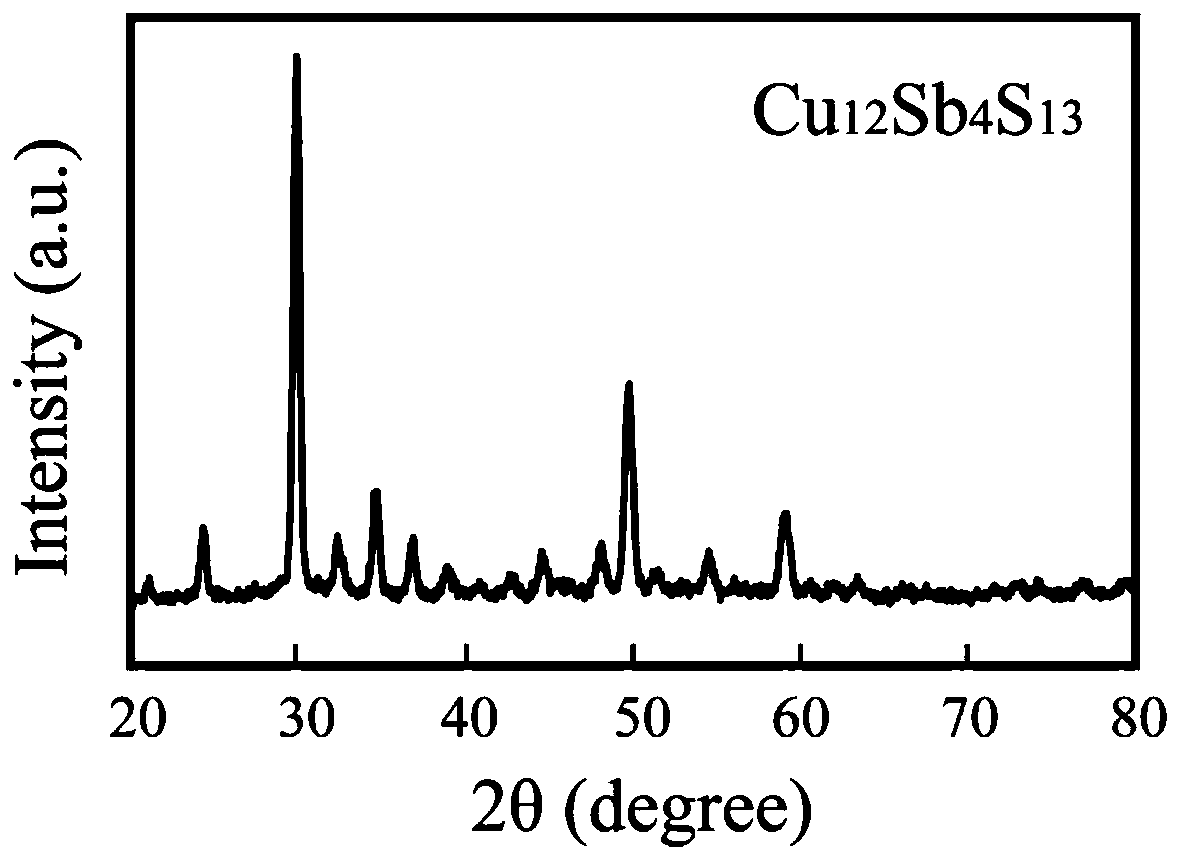

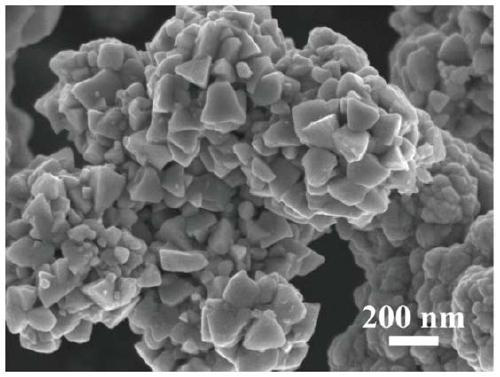

[0032] A preparation of nanometer ternary copper antimony sulfide (Cu 12 Sb 4 S 13 ) particle method, comprising the steps of:

[0033] (1) Pour 3 mmol of antimony acetate powder as the antimony source into 15 ml of glacial acetic acid solvent, and complete the dissolution of the antimony acetate powder by ultrasonication for 30 minutes to obtain a 0.2 mol / L antimony acetate solution.

[0034] (2) Pour 0.6 mmol of copper acetate dihydrate powder into 70 ml of ethylene glycol methyl ether solution, and dissolve it completely by stirring. Then 0.5 mL of diethanolamine is poured into the above solution, and the color of the solution changes from blue-green to blue-purple; then 0.68 mmol of thiourea is poured into the above solution, and the color of the solution becomes light yellow; then 1 mL of antimony acetate solution (1 ) was poured into the above solution, and the solution became transparent and colorless. Put the prepared solution above into a hydrothermal reaction ket...

Embodiment 2

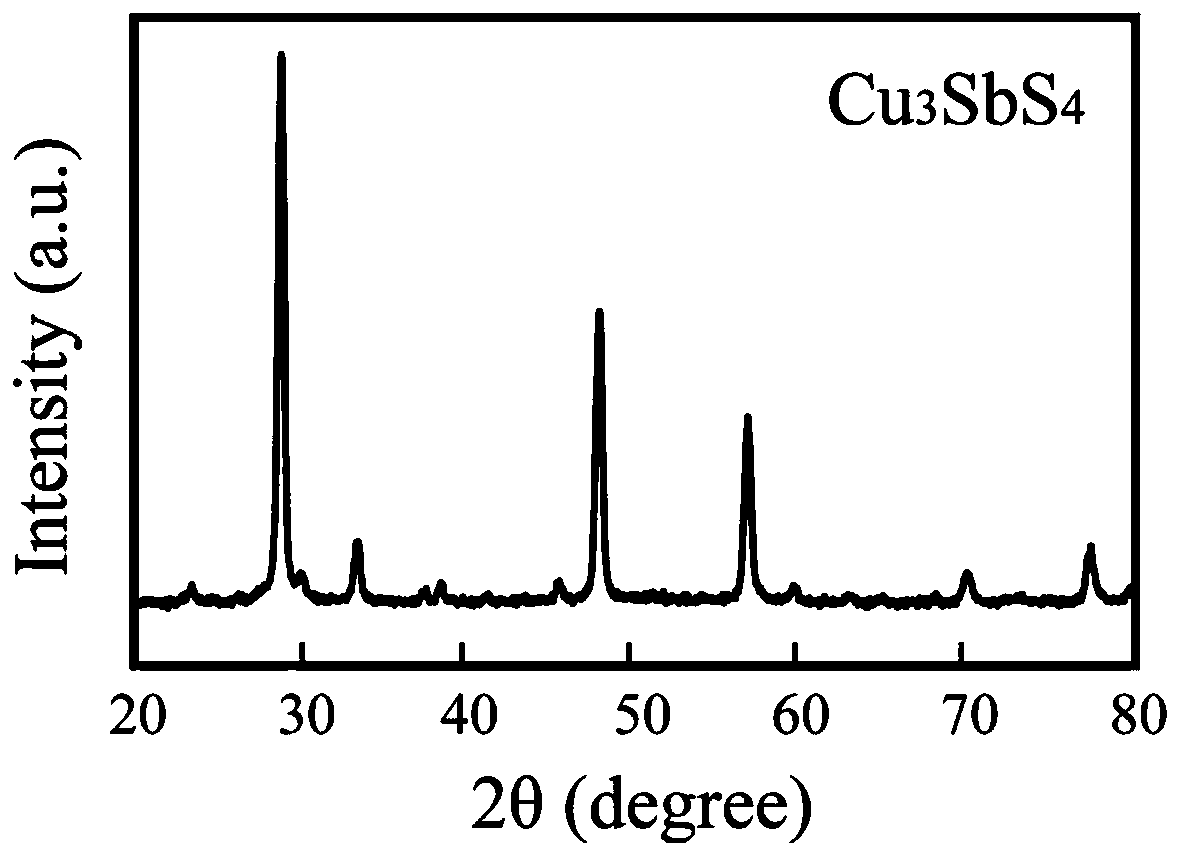

[0038] A preparation of nanometer ternary copper antimony sulfide (Cu 3 Sb 4 ) particle method, comprising the steps of:

[0039] (1) Pour 3 mmol of antimony acetate powder as the antimony source into 15 ml of glacial acetic acid solvent, and complete the dissolution of the antimony acetate powder by ultrasonication for 30 minutes to obtain a 0.2 mol / L antimony acetate solution.

[0040] (2) Pour 9 mmol of copper acetate dihydrate powder into 250 ml of ethylene glycol methyl ether solution, and dissolve it completely by stirring. Then pour 1mL of diethanolamine into the above solution, and the color of the solution changes from blue-green to blue-purple; then pour 105 mmoles of thiourea into the above solution, and the color of the solution turns into light yellow; then add 15mL of antimony acetate solution (1) Pour into the above solution, the solution becomes transparent and colorless. Put the prepared solution above into a hydrothermal reaction kettle, and the hydrotherm...

Embodiment 3

[0042] A preparation of nanometer ternary copper antimony sulfide (CuSbS 2 ) particle method, comprising the steps of:

[0043] (1) Pour 3 mmol of antimony acetate powder as the antimony source into 15 ml of glacial acetic acid solvent, and complete the dissolution of the antimony acetate powder by ultrasonication for 30 minutes to obtain a 0.2 mol / L antimony acetate solution.

[0044] (2) Pour 0.6 mmol of copper acetate dihydrate powder into 70 ml of ethylene glycol methyl ether solution, and dissolve it completely by stirring. Then 0.5 milliliters of diethanolamine is poured into the above-mentioned solution, and the color of the solution changes from blue-green to blue-purple; then 1.5 mmoles of thiourea are poured into the above-mentioned solution, and the color of the solution becomes pale yellow; then 3 milliliters of antimony acetate solution ( 1) Pour into the above solution, the solution becomes transparent and colorless. Pour the above prepared solution into the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com