Preparation method of high-strength weather resistant asbestos tile

A kind of asbestos tile, high-strength technology, applied to the roof, coating, roof covering and other directions using tiles/slate tiles, can solve the problems of poor weather resistance, poor strength of asbestos tiles, etc., to improve waterproof performance, small thermal expansion coefficient, The effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

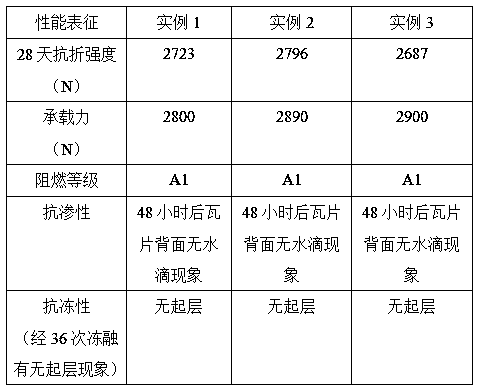

Examples

example 1

[0027]Take nano-titanium dioxide powder, nano-tin antimony oxide powder, deionized water, KH-570, OP-10, sodium polyacrylate, and mix nano-titanium dioxide powder, nano-tin antimony oxide powder and deionized water evenly to obtain a suspension. Add KH-570, OP-10 and sodium polyacrylate to the suspension, and carry out magnetic stirring treatment to obtain the reaction solution. Adjust the pH value of the reaction solution and carry out stirring and dispersion treatment to obtain the composite nano slurry; the acrylate emulsion, Composite nano slurry, hollow glass microspheres and deionized water are evenly mixed to obtain a composite coating; cement, yellow sand, asbestos fibers, asphalt, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder, water reducing agent, deionized water, mix cement, yellow sand, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder and deionized water, and stir to obtain mixture A. Add asbes...

example 2

[0029] Take nano-titanium dioxide powder, nano-tin antimony oxide powder, deionized water, KH-570, OP-10, sodium polyacrylate, and mix nano-titanium dioxide powder, nano-tin antimony oxide powder and deionized water evenly to obtain a suspension. Add KH-570, OP-10 and sodium polyacrylate to the suspension, and carry out magnetic stirring treatment to obtain the reaction solution. Adjust the pH value of the reaction solution and carry out stirring and dispersion treatment to obtain the composite nano slurry; the acrylate emulsion, Composite nano slurry, hollow glass microspheres and deionized water are evenly mixed to obtain a composite coating; cement, yellow sand, asbestos fibers, asphalt, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder, water reducing agent, deionized water, mix cement, yellow sand, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder and deionized water, and stir to obtain mixture A. Add asbe...

example 3

[0031] Take nano-titanium dioxide powder, nano-tin antimony oxide powder, deionized water, KH-570, OP-10, sodium polyacrylate, and mix nano-titanium dioxide powder, nano-tin antimony oxide powder and deionized water evenly to obtain a suspension. Add KH-570, OP-10 and sodium polyacrylate to the suspension, and carry out magnetic stirring treatment to obtain the reaction solution. Adjust the pH value of the reaction solution and carry out stirring and dispersion treatment to obtain the composite nano slurry; the acrylate emulsion, Composite nano slurry, hollow glass microspheres and deionized water are evenly mixed to obtain a composite coating; cement, yellow sand, asbestos fibers, asphalt, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder, water reducing agent, deionized water, mix cement, yellow sand, ferrosilicon nitride particles, ferrosilicon nitride powder, silicon carbide powder and deionized water, and stir to obtain mixture A. Add asbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com