High-entropy carbide nano-powder and preparation method thereof

A nano-powder and carbide technology, which is applied in the fields of carbon compounds, chemical instruments and methods, and inorganic chemistry, can solve the problems of difficult to obtain nano-scale high-entropy carbide powders, and achieve low cost, small particle size, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 1.89g of titanium tetrachloride, 2.33g of zirconium tetrachloride, 3.20g of hafnium tetrachloride, 2.70g of niobium pentachloride, and 3.58g of tantalum pentachloride into 50g of absolute ethanol, stir to dissolve it completely, Add 3.43g of furfuryl alcohol resin, react in a constant temperature water bath at 60°C for 1 hour, and dry the obtained precursor in an oven at 80°C to obtain a xerogel. Place the dry gel in a graphite furnace under an argon atmosphere for heat treatment at 2000°C for 1 hour to form a single-phase high-entropy carbide. After the reaction, the sample is cooled to room temperature with the furnace to obtain a high-entropy carbide nanopowder .

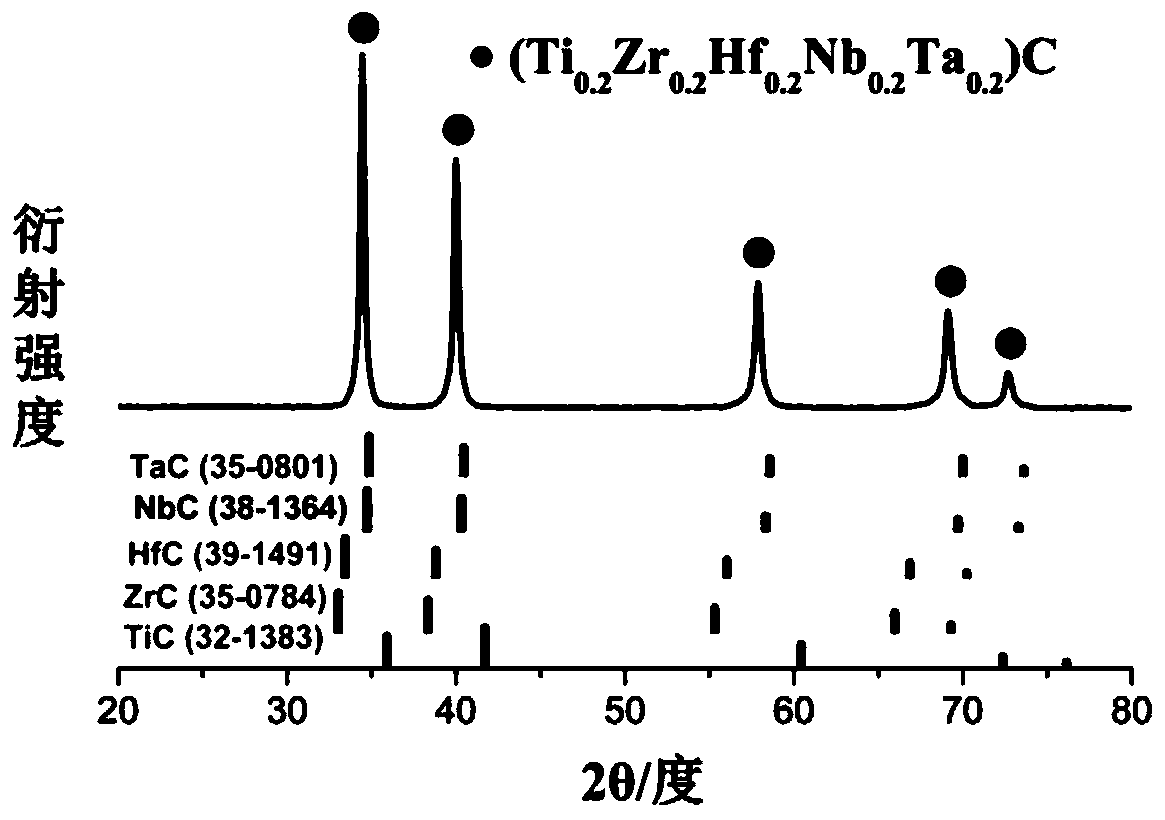

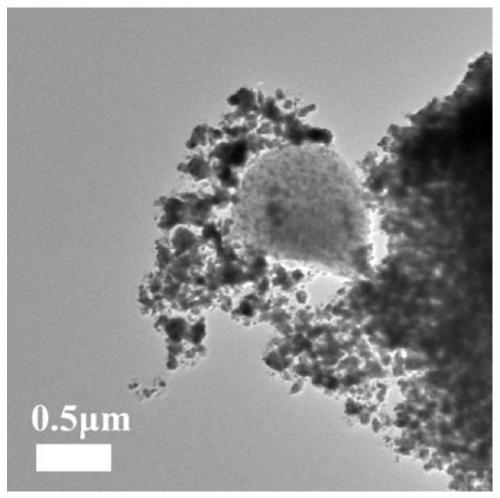

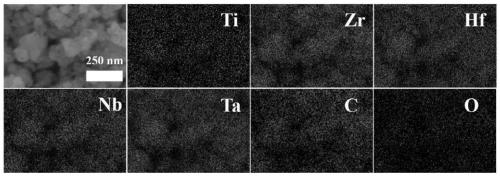

[0031] In the experiment, the obtained single-phase (Ti 0.2 Zr 0.2 f 0.2 Nb 0.2 Ta 0.2 ) XRD diffraction pattern of C such as figure 1 shown in the transmission electron micrograph figure 2 As shown, the average particle size of the high-entropy carbide nano-powder is 132nm; the element distri...

Embodiment 2

[0033] Add 1.89g of titanium tetrachloride, 2.33g of zirconium tetrachloride, 3.20g of hafnium tetrachloride, 1.57g of vanadium trichloride, and 3.58g of tantalum pentachloride into 50g of absolute ethanol, stir to dissolve it completely, After adding 3.58 g of furfuryl alcohol resin and reacting in a constant temperature water bath at 70° C. for 1 hour, the obtained precursor was dried in an oven at 90° C. to obtain a xerogel. Place the dry gel in a graphite furnace under an argon atmosphere for heat treatment at 1800°C for 1 hour to form a single-phase high-entropy carbide. After the reaction, the sample is cooled to room temperature with the furnace to obtain a high-entropy carbide nanopowder .

[0034] It was detected that: the obtained high-entropy carbide (Ti 0.2 Zr 0.2 f 0.2 V 0.2 Ta 0.2 ) The particle size of the C nanometer powder is concentrated at 165nm, and the oxygen content is 0.13wt%.

Embodiment 3

[0036]Add 3.40g of tetrabutyl titanate, 2.33g of zirconium tetrachloride, 3.20g of hafnium tetrachloride, 1.57g of vanadium trichloride, and 2.73g of molybdenum pentachloride into 50g of absolute ethanol, stir to dissolve completely , adding 3.69g of furfuryl alcohol resin, reacting in a constant temperature water bath at 60°C for 1 hour, then drying the obtained precursor in an oven at 70°C to obtain xerogel. Place the dry gel in a graphite furnace under an argon atmosphere for heat treatment at 1900°C for 1 hour to form a single-phase high-entropy carbide. After the reaction, the sample is cooled to room temperature with the furnace to obtain a high-entropy carbide nanopowder . All the other operations are the same as described in Example 1.

[0037] It was detected that: the obtained high-entropy carbide (Ti 0.2 Zr 0.2 f 0.2 V 0.2 Mo 0.2 ) The particle size of the C nanometer powder is concentrated at 121nm, and the oxygen content is 0.28wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com