A kind of resin material for oil and gas well casing plugging and preparation method thereof

A technology of resin materials and oil and gas wells, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to cure at right angles, insufficient air tightness, cracks, etc., to facilitate ground construction operations and simple and easy construction process The effect of small line and volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

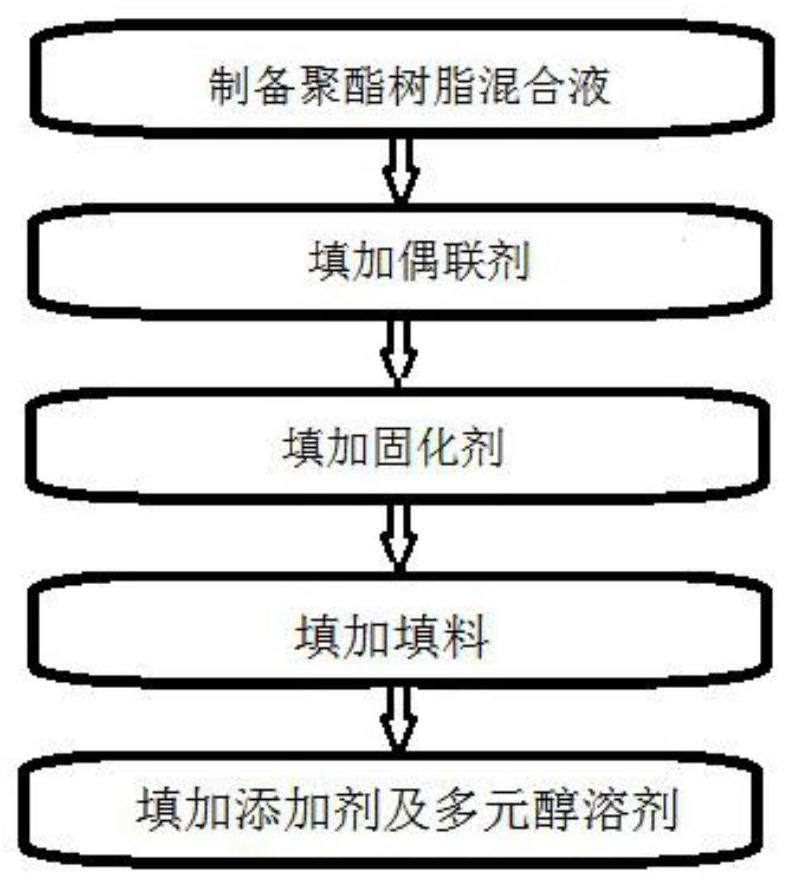

Method used

Image

Examples

Embodiment 1

[0033] A resin material for oil and gas well casing plugging, including polyester resin, curing agent, filler, coupling agent, additive and polyol solvent; the proportion of each composition is: 65%-85% polyester resin , 0.6%-3% curing agent, 3%-5% filler, 0.5%-1.5% coupling agent, 1%-3% additive, and the rest are polyol solvents; the polyester resin is ethylene One or more of methyl toluene, vinyl acetate, terephthalic acid, and trimellitic anhydride.

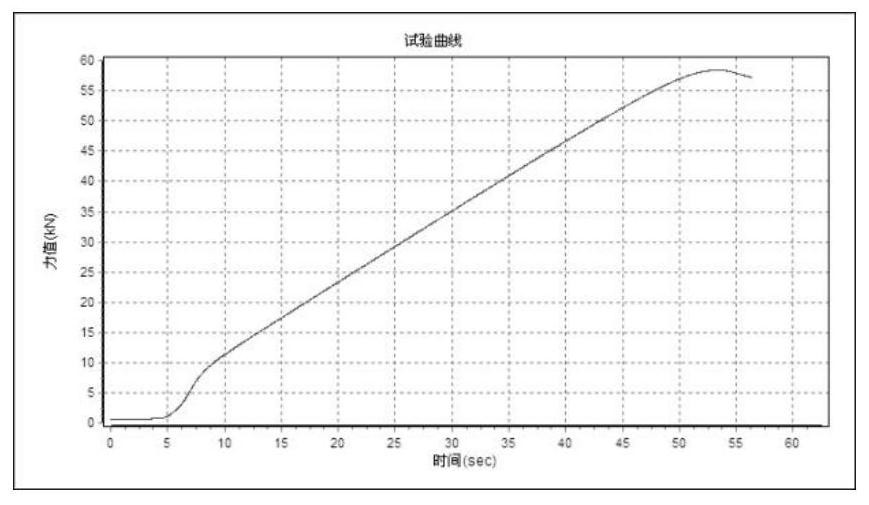

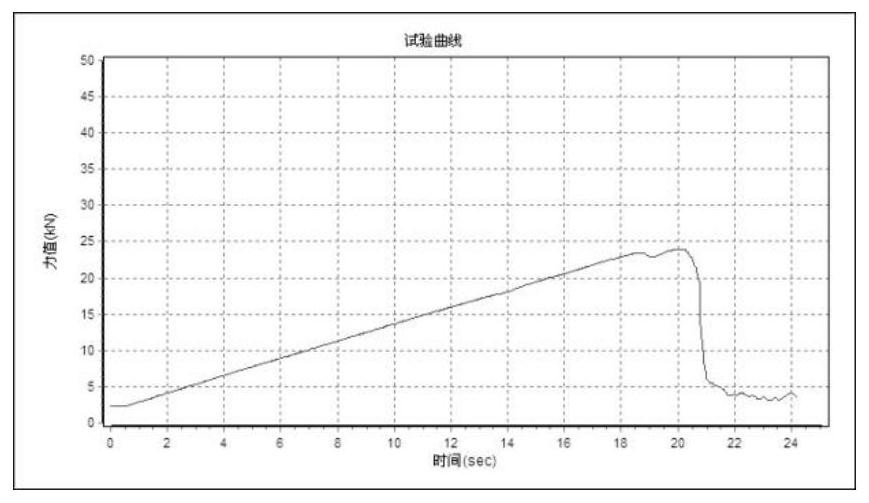

[0034] In actual use, the initial viscosity is 20-80mPa·s, the system undergoes a polymerization and curing reaction, and the gap between the formation and the casing is cemented and sealed. The curing time is 4-24 hours at a reservoir temperature of 50-70°C. Pressure resistance 15-65MPa can be adjusted according to specific construction requirements.

[0035] The resin material for oil and gas well casing leak plugging of the present invention has high strength, good cementation, and a small volume change rate, and is not on...

Embodiment 2

[0037] A resin material for oil and gas well casing plugging, which is different from Embodiment 1 in that the curing agent is one or more of naphthalene peroxide, benzoyl peroxide, and cyclohexanone peroxide.

[0038] In actual use, the curing agent is one or more technical solutions in naphthalene peroxide, benzoyl peroxide, and cyclohexanone peroxide, which can reduce the viscosity of the corresponding resin, make it fluid, and have good Injection.

Embodiment 3

[0040] A resin material for oil and gas well casing plugging, which is different from Embodiment 1 in that the filler is one or more of silicon dioxide, calcium carbonate, and mica powder.

[0041] In actual use, the filler is one or more technical solutions of silicon dioxide, calcium carbonate, and mica powder, which effectively enhances the mechanical properties of the resin material for plugging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com