Double-side magnetically responsive particles, and preparation method and applications thereof

A magnetic response, two-sided technology, applied in the direction of dehydration/demulsification by chemical methods, separation of immiscible liquids, etc. The effect of interface activity, cost saving of pharmaceuticals, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

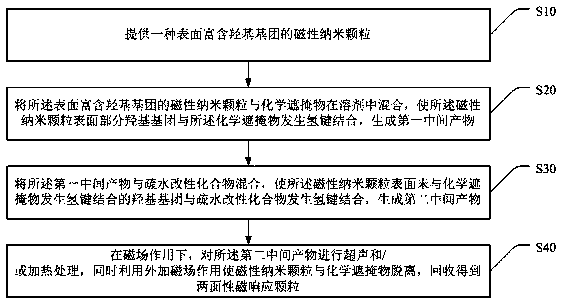

Method used

Image

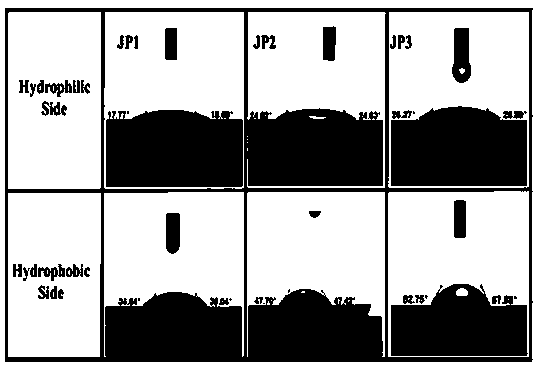

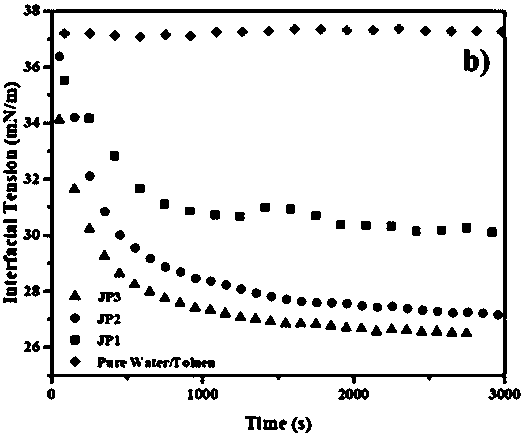

Examples

Embodiment 1

[0057] 1. Preparation of magnetic iron ferric oxide nanoparticles: Dissolve 8.6 g of ferric chloride hexahydrate and 2 g of trisodium citrate in 20 mL of water, add 140 mL of ethylene glycol, and stir in a water bath at 60°C for 15 minutes until the solution is clear and transparent Add 8 g of anhydrous sodium acetate, stir for 10 min, transfer to a 200 mL polytetrafluoroethylene liner, conduct hydrothermal reaction at 200 °C for 10 h, wash with distilled water and ethanol three times in turn after cooling, and vacuum dry at 60 °C for 10 h. Magnetic ferric oxide nanoparticles were prepared.

[0058] 2. Surface chemical masking of magnetic particles: Take 2 g of ferric oxide nanoparticles and disperse them in 400 mL of water, and mix them with 50 g of potato starch particles. After mechanical stirring for 24 h, wait for sedimentation and remove the supernatant, add 400 ml of ethanol, and wash 4 times like this.

[0059] 3. Hydrophobic modification of the surface of magnetic pa...

Embodiment 2

[0062] 1. Preparation of magnetic iron ferric oxide nanoparticles: Dissolve 13.9 g of ferrous sulfate heptahydrate and 32.44 g of ferric chloride hexahydrate in a mixed solvent of 100 mL of water and 400 mL of ethylene glycol, and add them to a three-necked flask In the nitrogen atmosphere, the precipitating agent ammonia water was added to adjust the pH to >10, and the reaction was stirred at a constant speed in a water bath at 50°C for 3 h. After the black ferric oxide nanoparticles were formed, they were collected by centrifugation, washed and dried with water and ethanol for 3 times in sequence. , and finally dried in a vacuum drying oven at 60° C. to obtain magnetic Fe3O4 nanoparticles.

[0063] 2. Chemical masking of the surface of magnetic particles: 0.5 g of ferric oxide nanoparticles prepared were dispersed into 400 mL of ethanol, and 50 g of silicon dioxide particles were mixed in at the same time. After mechanical stirring for 3 h, centrifuge at low speed and remove...

Embodiment 3

[0067] 1. Preparation of magnetic iron ferric oxide nanoparticles: Dissolve 13.9g of ferrous sulfate heptahydrate and 32.44g of ferric chloride hexahydrate in a mixed solvent of 100mL of water and 400mL of ethylene glycol, and add them to a three-necked flask. The precipitant ammonia water added in the nitrogen atmosphere was adjusted to pH > 10, and the reaction was stirred at a constant speed in a water bath at 50°C for 3 hours. After the formation of black iron ferric oxide nanoparticles, they were collected by centrifugation, washed and dried with water and ethanol for 3 times, and finally placed in Drying in a vacuum oven at 60°C to obtain magnetic ferric oxide nanoparticles was prepared.

[0068] 2. Chemical masking of the surface of magnetic particles: take 0.5 g of ferric oxide nanoparticles prepared and disperse them into 400 mL of water, mix 32 g of kaolin powder, 0.05 g of NaCl, and 0.01 g of KCl at the same time, adjust the pH to 8.2, and stir mechanically After 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com