Cement-based polymer waterproof mortar and preparation method thereof

A technology for waterproof mortar and polymer, applied in the field of building materials, can solve the problems of acid and alkali resistance, poor corrosion resistance, increased price and cost of cement mortar, unscientific formula design, etc., and achieves low water absorption, low preparation cost, good quality The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

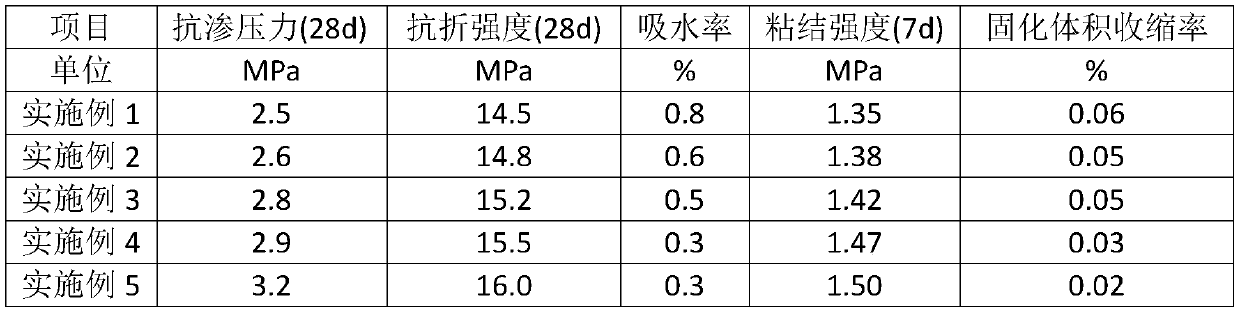

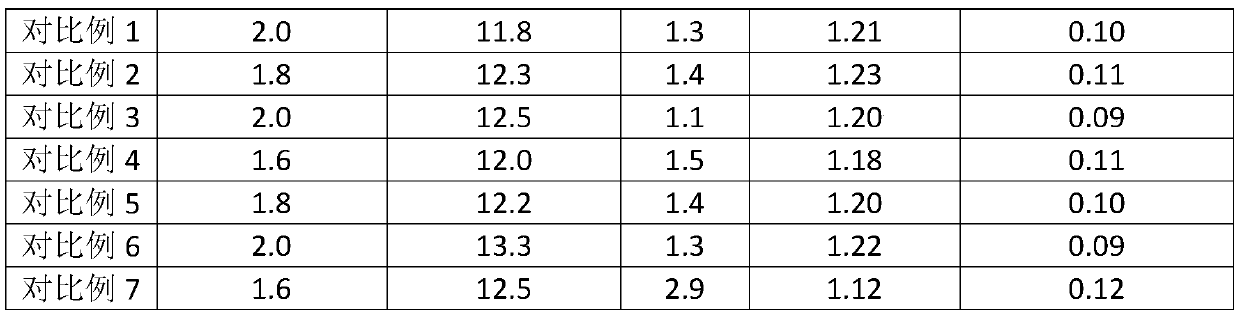

Examples

Embodiment 1

[0032]A cement-based polymer waterproof mortar, made of the following raw materials in parts by weight: 5 parts of 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched polyamino acid, 2 parts of fatty acid-based addition polymer, boric acid 0.5 parts of calcium, 1 part of nano aluminum sol, 10 parts of volcanic stone powder, 100 parts of Portland cement, 3 parts of palygorskite powder, 3 parts of glass fiber powder, 3 parts of blast furnace slag powder, 20 parts of styrene-acrylic emulsion, lauryl polyoxygen Sodium vinyl ether sulfate modified cross-linked superabsorbent resin 1 part, fine sand 80 parts, water 80 parts.

[0033] Wherein, the fatty acid-based addition polymer is prepared by copolymerization of dimer acid, 3-(methacryloxy)propyltrimethoxysilane, pentaerythritol monooleate, and poly(ethylene glycol) phenyl ether acrylate. become.

[0034] The preparation method of the 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched polyamin...

Embodiment 2

[0041] A cement-based polymer waterproof mortar, which is made of the following raw materials in parts by weight: 6.5 parts of 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched polyamino acid, 3 parts of fatty acid-based addition polymer, boric acid 1 part of calcium, 1.5 parts of nano aluminum sol, 11 parts of volcanic stone powder, 100 parts of Portland cement, 4 parts of palygorskite powder, 3.5 parts of glass fiber powder, 4 parts of steel slag powder, 22 parts of styrene-acrylic emulsion, lauryl polyoxyethylene Sodium ether sulfate modified cross-linked superabsorbent resin 1.5 parts, fine sand 90 parts, water 85 parts.

[0042] Wherein, the fatty acid-based addition polymer is prepared by copolymerization of dimer acid, 3-(methacryloxy)propyltrimethoxysilane, pentaerythritol monooleate, and poly(ethylene glycol) phenyl ether acrylate. become.

[0043] The preparation method of the 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched ...

Embodiment 3

[0050] A cement-based polymer waterproof mortar, made of the following raw materials in parts by weight: 7.5 parts of 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched polyamino acid, 3.5 parts of fatty acid-based addition polymer, boric acid 1.5 parts of calcium, 2 parts of nano aluminum sol, 13 parts of volcanic stone powder, 100 parts of Portland cement, 5 parts of palygorskite powder, 4 parts of glass fiber powder, 6.5 parts of red mud powder, 25 parts of styrene-acrylic emulsion, lauryl polyoxygen Sodium vinyl ether sulfate modified cross-linked superabsorbent resin 2 parts, fine sand 100 parts, water 90 parts.

[0051] Wherein, the fatty acid-based addition polymer is prepared by copolymerization of dimer acid, 3-(methacryloxy)propyltrimethoxysilane, pentaerythritol monooleate, and poly(ethylene glycol) phenyl ether acrylate. become.

[0052] The preparation method of the 3-chloro-2-hydroxypropanesulfonic acid ionized modified hyperbranched polyamino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com