One-step method for preparing GQDs modified flaky TiO2/g-C3N4 heterojunction

A g-c3n4, heterojunction technology, applied in the field of solar photocatalytic materials, can solve the problems of easy recombination of photogenerated electrons and holes, low utilization rate of solar energy, etc., and achieve the effect of simple and fast method, low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

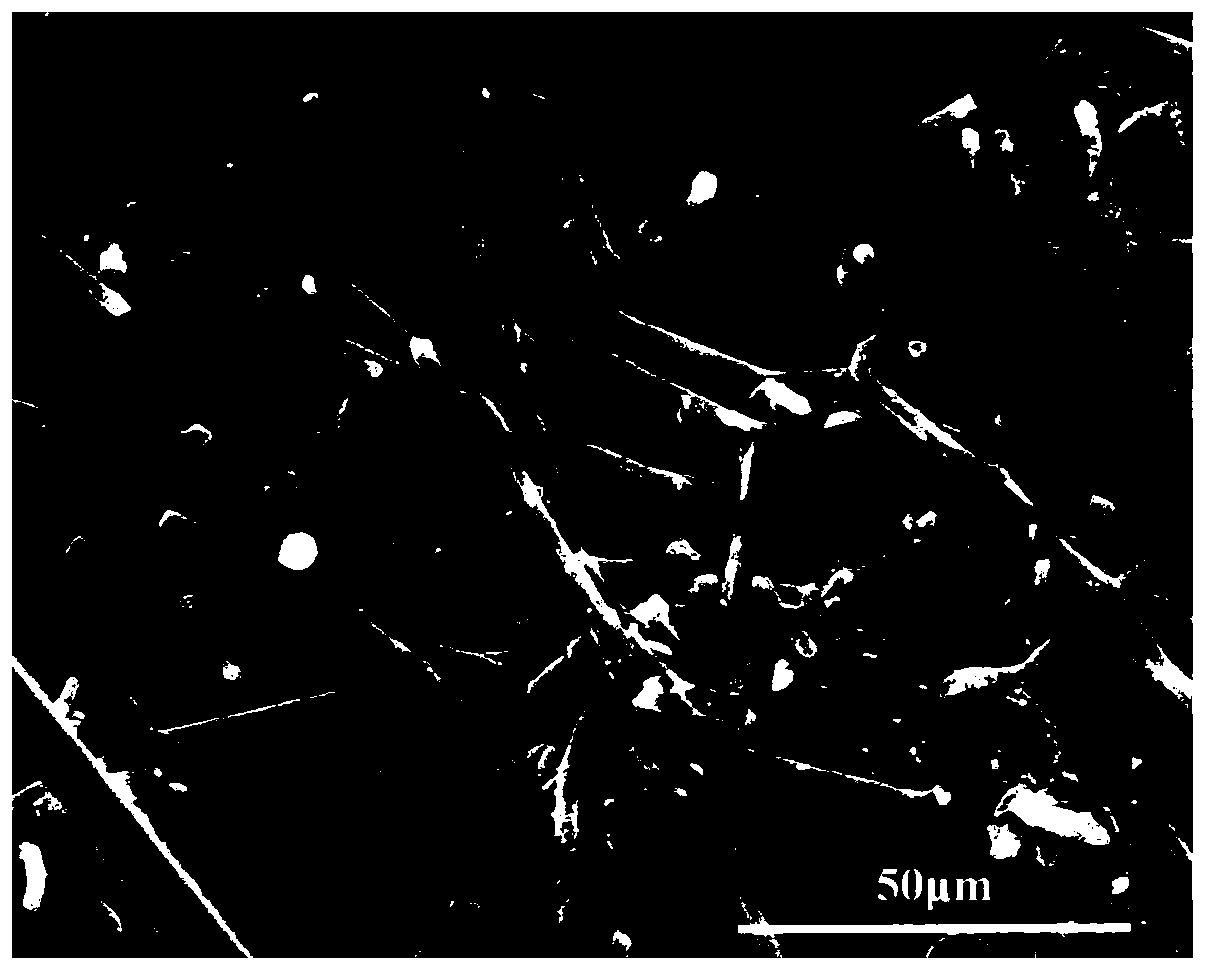

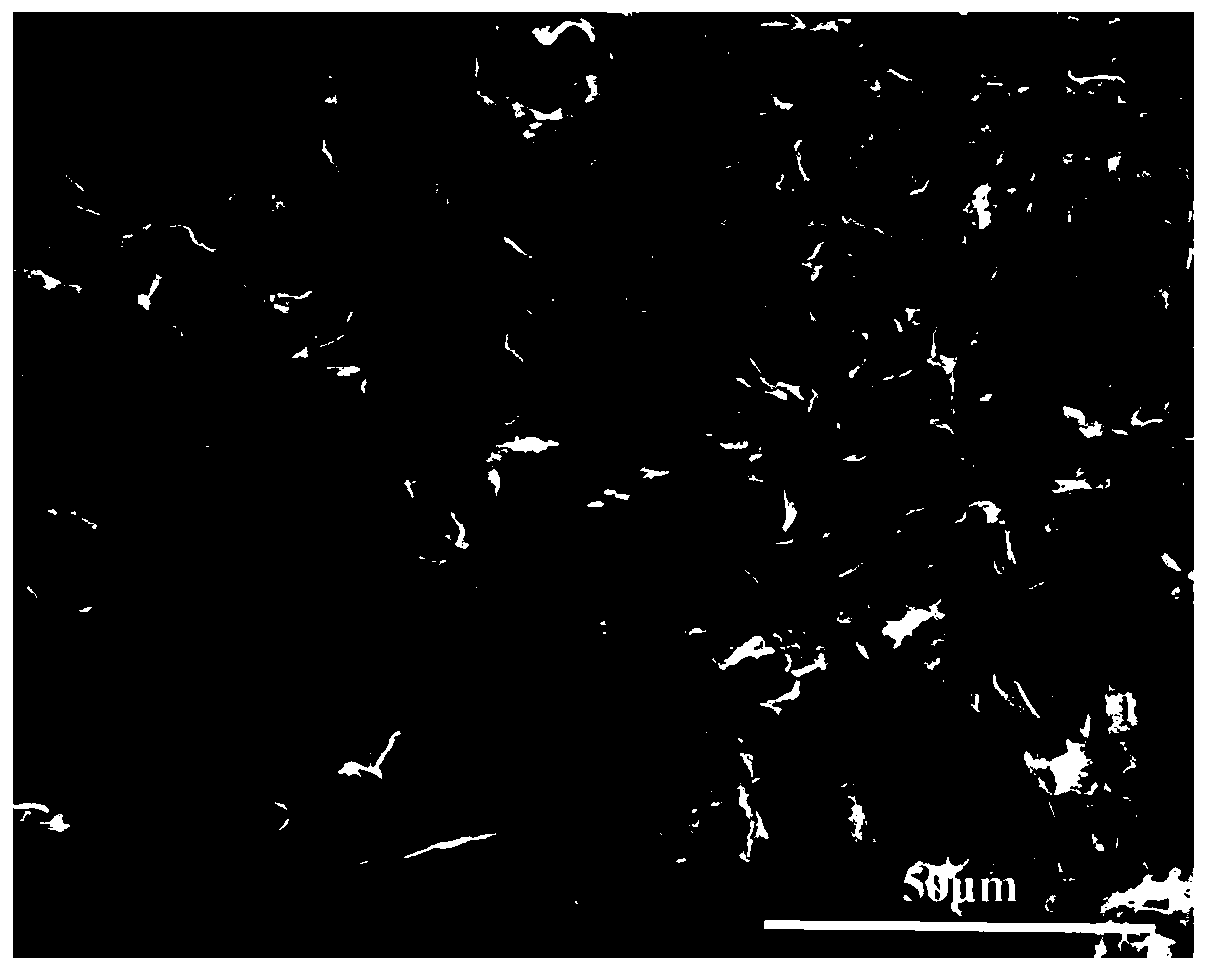

Image

Examples

Embodiment 1

[0026] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:3, and mix well to obtain solution A;

[0027] 2) Add polyvinylpyrrolidone with a mass ratio of 8% to solution A, and completely dissolve to obtain solution B;

[0028] 3) Add melamine powder with a mass ratio of 12.5% to solution B, and stir to obtain solution C;

[0029] 4) Add GQDs powder with a mass ratio of 0.1% to solution C, and ultrasonically disperse for 24 hours to obtain mixed solution D;

[0030] 5) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0031] 6) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

Embodiment 2

[0033] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol in a volume ratio of 1:1:2, and mix well to obtain solution A;

[0034] 2) Add polyvinylpyrrolidone with a mass ratio of 10% to solution A, and completely dissolve to obtain solution B;

[0035] 3) Add melamine powder with a mass ratio of 15% to solution B, and stir to obtain solution C;

[0036] 4) Add GQDs powder with a mass ratio of 0.15% to solution C, and ultrasonically disperse for 24 hours to obtain mixed solution D;

[0037] 5) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0038] 6) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

Embodiment 3

[0040] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:1, and mix them uniformly to obtain solution A;

[0041] 2) Add polyvinylpyrrolidone with a mass ratio of 12% to solution A, and completely dissolve to obtain solution B;

[0042] 3) Add melamine powder with a mass ratio of 17.5% to solution B, and stir to obtain solution C;

[0043] 4) Add GQDs powder with a mass ratio of 0.2% to solution C, and ultrasonically disperse for 24 hours to obtain mixed solution D;

[0044] 5) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0045] 6) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

[0046] GQDs have good biocompatibility, stable chemical properties, good up-conversion photolumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com