Temperature/pH double-sensitive high-strength nano composite hydrogel and preparation method thereof

A nanocomposite and hydrogel technology, applied in the field of hydrogel preparation, can solve the problems of inability to respond quickly to the environment, low mechanical strength, weak interaction, etc., and achieve simple mixing and heat dissipation, high tolerance, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090]The invention also discloses a method for preparing a temperature / pH dual-sensitive high-strength nanocomposite hydrogel, and the specific steps include:

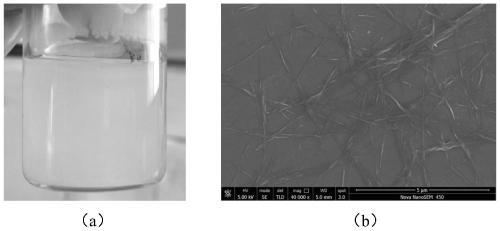

[0091] (1) Preparation of ascidian nanocellulose (TCNCs): isolate tunicin from true ascidian, hydrolyze with sulfuric acid, centrifuge after standing for a period of time, and then dialyze to neutral with deionized water to obtain uniform ascidian nanocellulose. Cellulose suspension, then the ascidian nanocellulose suspension prepared is lyophilized with a freeze dryer to obtain the described ascidian nanocellulose (TCNCs) of dry white floc;

[0092] (2) Preparation of ascidian nanocellulose (TCNCs) suspension: uniformly disperse the ascidian nanocellulose (TCNCs) prepared in step (1) in deionized water at room temperature to prepare ascidian nanocellulose suspensions with different mass fractions ;

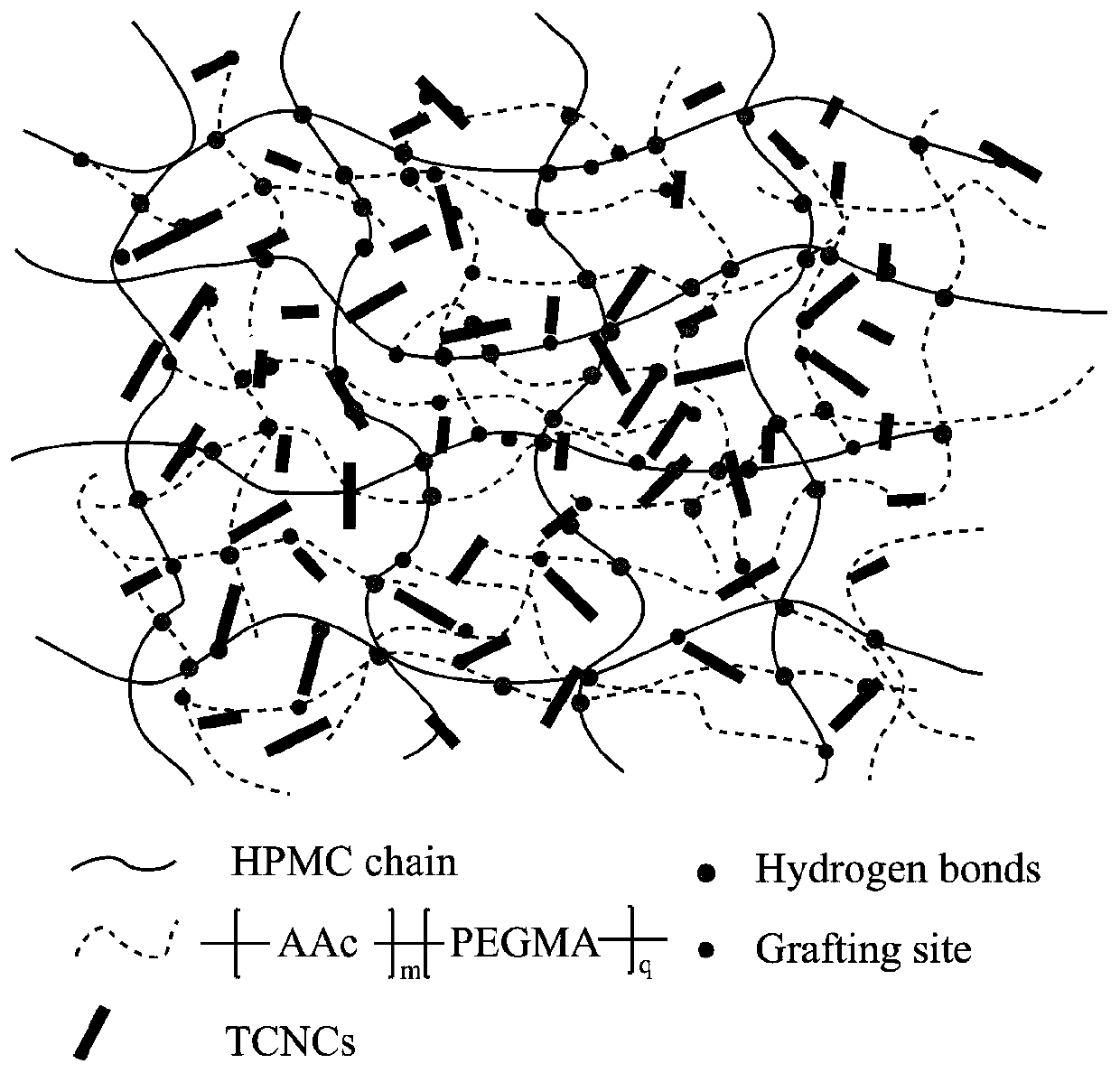

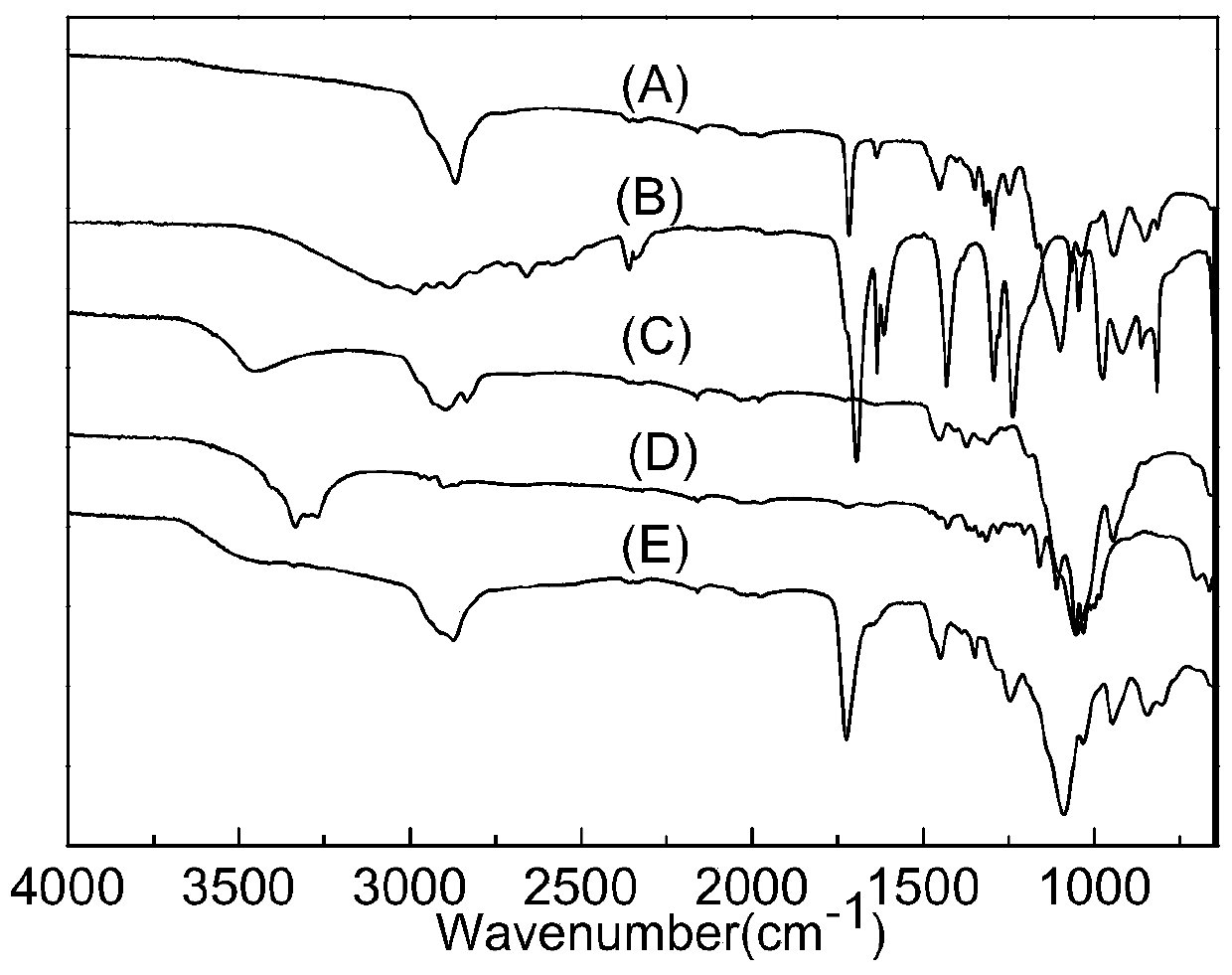

[0093] (3) Cross-linking reaction mixture: hydroxypropyl methylcellulose (HPMC) is uniformly dispersed in the ascidia...

Embodiment 1

[0103] A method for preparing a temperature / pH dual-sensitive high-strength nanocomposite hydrogel, specifically comprising the following steps:

[0104] In step (1), the tunicin is separated from the true sea squirt, hydrolyzed with an acid, centrifuged after standing for a period of time, and then dialyzed to neutrality with deionized water to obtain a uniform sea squirt nanocellulose suspension.

[0105] In step (2), the ascidian nanocellulose suspension prepared in step (1) is freeze-dried with a freeze dryer to obtain dry white flocculent ascidian nanocellulose (TCNCs).

[0106] In step (3), at room temperature, 0.05 g of the freeze-dried TCNCs prepared in step (2) was dissolved in 4 mL of deionized water, stirred overnight and ultrasonicated for 10 min to prepare a uniform TCNCs suspension.

[0107] In step (4), 0.3 g of HPMC is added into the system of step (3), stirred and mixed evenly.

[0108] In step (5), monomer PEGMA and monomer AAc (mass ratio: 70:30) are sequen...

Embodiment 2

[0116] As described in Example 1, the difference is that the quality of TCNCs is changed to 0.15g, and other preparation process conditions and process parameters remain unchanged, and a nanocomposite hydraulic gel with high-efficiency temperature / pH dual sensitivity and high strength is prepared. glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com