Novel ionic liquid composite medium and preparation method, application and application method thereof

An ionic liquid and composite medium technology, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of complex operation, lack of efficient homogeneous catalysts, reduce costs, etc., to achieve simple reaction process and operation, efficient homogeneous phase Catalytic conversion, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of ionic liquid composite medium and preparation method thereof, its steps are as follows

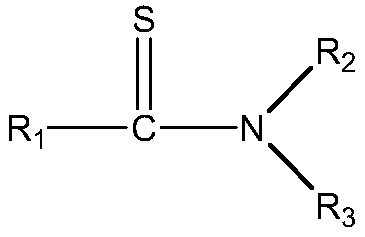

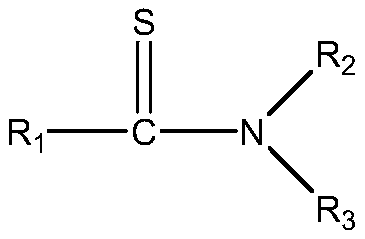

[0035] 1) First, mix thiopropionamide with AlCl at room temperature and nitrogen atmosphere 3 Mix and react for 2 hours with a substance ratio of 1:2.5 to obtain an ionic liquid solvent;

[0036] 2) Then, the 1-methyl-2-sulfopropylpyrazole chloride salt and AlCl 3 Mix and react at room temperature for 3 hours at a material ratio of 1:3 to obtain an ionic liquid catalyst;

[0037] 3) Finally, mix the solvent and the catalyst at room temperature to obtain a novel ionic liquid composite medium, wherein the molar percentage of the catalyst in the composite medium system is 15%.

[0038] The method for preparing 2,5-dimethylfuran by using the ionic liquid composite medium, the steps are as follows:

[0039] A. Under a nitrogen atmosphere, first add 2 g of cellulose pulp (polymerization degree range of 500 to 1000) into 20 g of ionic liquid composite medium, and stir and reac...

Embodiment 2

[0043] An ionic liquid composite medium and a preparation method thereof, the steps of which are as follows:

[0044] 1) First, thioisobutyramide was mixed with AlBr at room temperature under an argon atmosphere 3 Mixing and reacting for 1.5h with a substance ratio of 1:2 to obtain an ionic liquid solvent;

[0045] 2) Then, 1-hydrogen-2-hydroxy-4-methylpyrimidinium bromide and AlBr 3 Mix and react at room temperature for 2 hours at a material ratio of 1:2.1 to obtain an ionic liquid catalyst;

[0046] 3) Finally, a novel ionic liquid composite medium is obtained by mixing the solvent and the catalyst at room temperature, wherein the molar percentage of the catalyst in the medium system is 20%.

[0047] The method for preparing 2,5-dimethylfuran by using the ionic liquid composite medium, the steps are as follows:

[0048] A. Under an argon atmosphere, first add 2.5 g of microcrystalline cellulose (with a degree of polymerization ranging from 200 to 500) into 20 g of an ionic ...

Embodiment 3

[0052] An ionic liquid composite medium and a preparation method thereof, the steps of which are as follows:

[0053] 1) First, thiobenzamide was mixed with AlBr at room temperature and nitrogen atmosphere 3 Mix and react for 2 hours with a substance ratio of 1:2.5 to obtain an ionic liquid solvent;

[0054] 2) Then, 1-hydrogen-2-carboxy-5-methylpyrazine chloride salt and AlCl 3 Mixing and reacting for 3.5 hours with a substance molar ratio of 1:3.5 to obtain an ionic liquid catalyst;

[0055] 3) Finally, a new type of ionic liquid composite medium is obtained by mixing the above solvent and catalyst, wherein the mole percentage of the catalyst in the medium system is 18%.

[0056] Utilize described ionic liquid composite medium to prepare the method for 2,5-dimethylfuran, its steps are as follows:

[0057] A. Under a nitrogen atmosphere, first add 1.2 g of cotton linters (the degree of polymerization ranges from 1000 to 2000) into 20 g of ionic liquid composite medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com