Surface negatively-charged functional melamine sponge as well as preparation method and application thereof

A melamine sponge and negatively charged technology is applied in the field of functionalized melamine sponge and its preparation, and achieves the effects of easy availability of raw materials, simple operation and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Pretreatment of materials:

[0049] The melamine sponge was cut into 3cm×3cm×3cm squares, then soaked in acetone, ethanol, and deionized water for 10 minutes, then ultrasonically cleaned for 10 minutes, and then dried in an electric blast drying oven at 60°C for later use. This step can effectively remove a small amount of impurities in the melamine sponge.

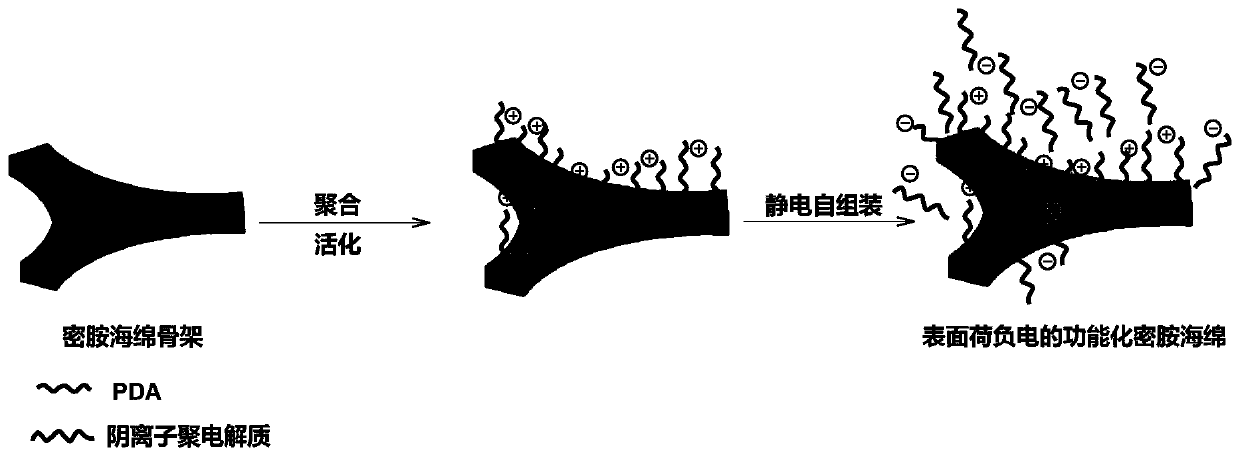

[0050] 2. Modification of melamine sponge:

[0051] (1) Soak the melamine sponge in 200mL with a concentration of 2mg·mL -1 In the dopamine solution (the solvent adopted by the dopamine solution is a Tris-HCl buffer solution with a pH of 8.5 and a concentration of 50 mM), the dopamine is fully oxidized and polymerized on the surface of the substrate, the reaction temperature is 25 ° C, and the time is 12 hours to obtain polydopamine Modified melamine sponge;

[0052] (2) Soak the polydopamine-modified melamine sponge in step (1) in a solution whose pH is adjusted to 3 with hydrochloric acid and activate for 6...

Embodiment 2

[0055] 1. Pretreatment of materials:

[0056] The melamine sponge was cut into 3cm×3cm×3cm squares, then soaked in acetone, ethanol, and deionized water for 10 minutes, then ultrasonically cleaned for 10 minutes, and then dried in an electric blast drying oven at 60°C for later use. This step can effectively remove a small amount of impurities in the melamine sponge.

[0057] 2. Modification of melamine sponge:

[0058] (1) Soak the melamine sponge in 200mL with a concentration of 2mg·mL -1 In the dopamine solution (the solvent adopted by the dopamine solution is a Tris-HCl buffer solution with a pH of 8.5 and a concentration of 50 mM), the dopamine is fully oxidized and polymerized on the surface of the substrate, the reaction temperature is 25 ° C, and the time is 12 hours to obtain polydopamine Modified melamine sponge;

[0059] (2) Soak the polydopamine-modified melamine sponge in step (1) in a solution whose pH is adjusted to 3 with hydrochloric acid and activate for 6...

Embodiment 3

[0062] 1. Pretreatment of materials:

[0063] The melamine sponge was cut into 3cm×3cm×3cm squares, then soaked in acetone, ethanol, and deionized water for 10 minutes, then ultrasonically cleaned for 10 minutes, and then dried in an electric blast drying oven at 60°C for later use. This step can effectively remove a small amount of impurities in the melamine sponge.

[0064] 2. Modification of melamine sponge:

[0065] (1) Soak the melamine sponge in 200mL with a concentration of 2mg·mL -1 In the dopamine solution (the solvent adopted by the dopamine solution is a Tris-HCl buffer solution with a pH of 8.5 and a concentration of 50 mM), the dopamine is fully oxidized and polymerized on the surface of the substrate, the reaction temperature is 25 ° C, and the time is 12 hours to obtain polydopamine Modified melamine sponge;

[0066] (2) Soak the polydopamine-modified melamine sponge in step (1) in a solution whose pH is adjusted to 3 with hydrochloric acid and activate for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com