Coal-based active coke hole structure grouping regulation method based on coal internal ash catalytic activation

A catalytic activation and activated coke technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high cost, large amount of activator used in chemical activation, adsorption kinetics of microporous carbon materials, universal application Poor performance and other problems, to achieve the effect of reducing preparation cost, low cost, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

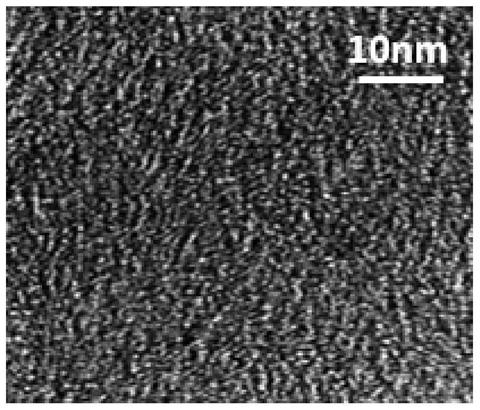

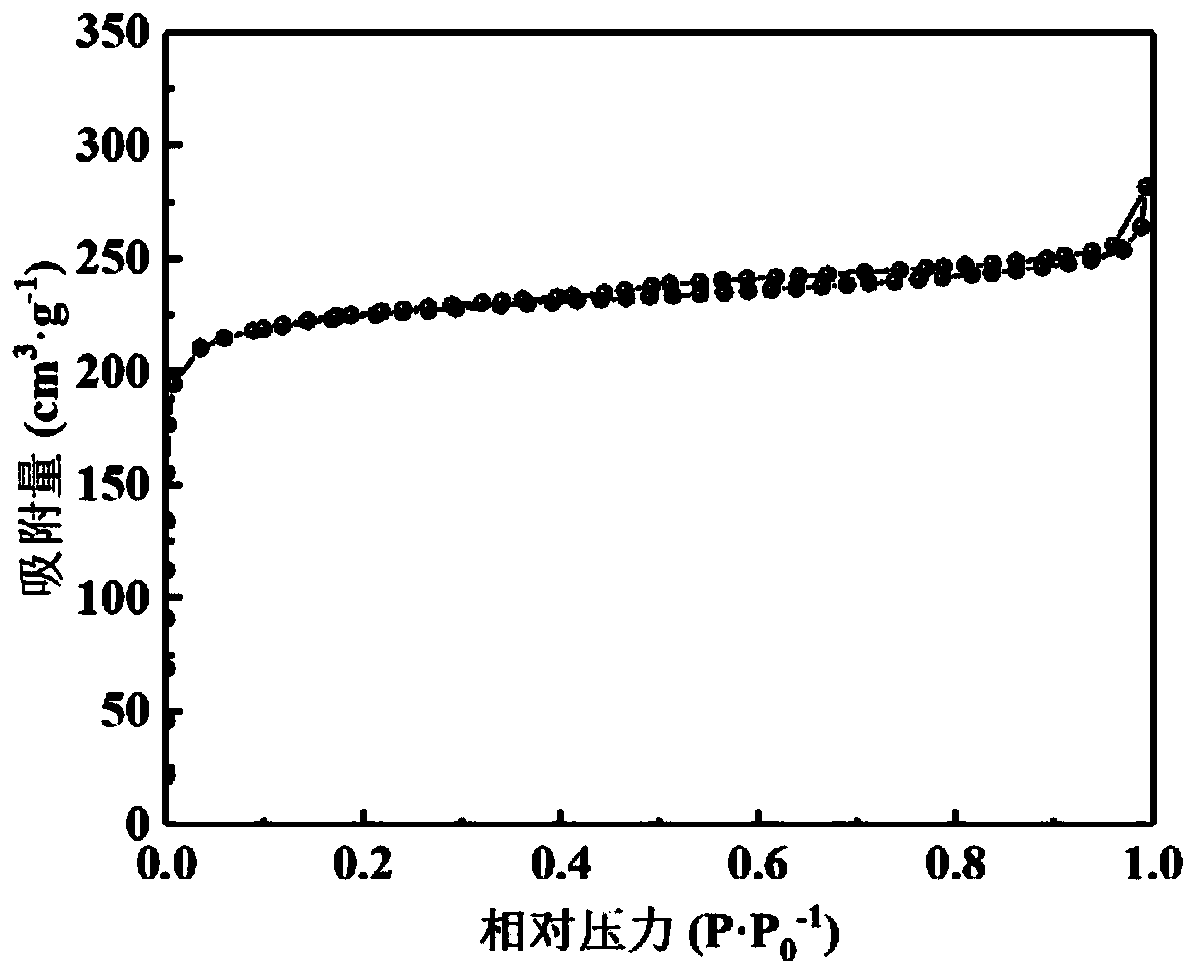

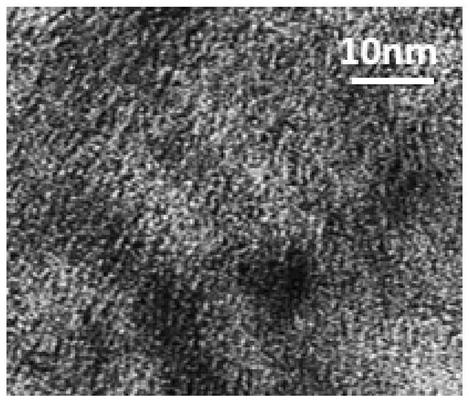

[0034] Specific implementation mode 1: The coal-based active coke pore structure matching control method based on the catalytic activation of coal internal ash in this embodiment is carried out according to the following steps:

[0035] 1. Raw material refinement

[0036] The raw materials are crushed, ground and sieved in sequence to obtain fine coal powder;

[0037] 2. Chemical deashing pretreatment

[0038] Mix the pulverized coal in the previous step with an acid solution or alkali solution, heat and stir for 10 to 12 hours, then wash with deionized water until the pH is neutral and dry, or perform the following operations in sequence for the pulverized coal in the previous step: mix with acid and alkali The mixed solution is mixed evenly, heated and stirred and washed to obtain the mixture;

[0039] 3. High temperature activation

[0040] Put the mixture in step 2 in the atmosphere furnace, raise the temperature of the atmosphere furnace to 700°C-1000°C and keep the te...

specific Embodiment approach 2

[0048] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the fixed carbon content of the raw material is 30% to 80%, the volatile matter content is 20% to 50%, the ash content is 0 to 50%, and the moisture The content is 0-30%; the elemental analysis requirements of the coal type are: the content of carbon element is 50%-80%, the content of hydrogen element is 0%-10%, the content of oxygen element is 0%-30%, and the raw material is within the above range A coal or a mixture of multiple coals in any proportion; the particle size of the finely divided coal powder is 40 mesh to 300 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the acid solution in step two is hydrochloric acid (HCl), hydrofluoric acid (HF), sulfuric acid (H 2 SO 4 ), nitric acid (HNO 3 ) or acetic acid (CH 3 COOH); Wherein, the concentration of hydrochloric acid solution is 0.1~20M, the concentration of hydrofluoric acid solution is 1%~50%, the concentration of sulfuric acid solution is 0.1~20M, the concentration of nitric acid solution is 0.1~20M, the concentration of acetic acid solution is 1% to 50%. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com