Peach gum polyferose and application thereof

A peach gum polysaccharide and reaction technology, applied in peach gum polysaccharide iron and its application field, can solve the problems of high price of lactoferrin, etc., achieve the effects of preventing respiratory tract infection and diarrhea, improving the immune system, and high iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

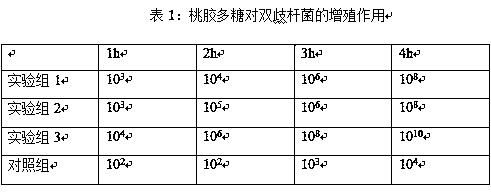

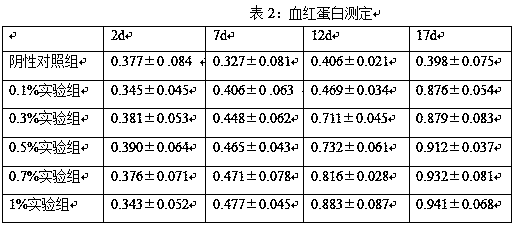

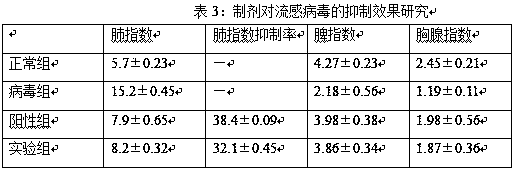

Examples

Embodiment 1

[0034] Preparation of Peach Gum Polysaccharide Extract:

[0035] S11: Wash 50g of raw peach gum to remove impurities, add 1000ml of water to soak for 8h, heat the homogenate to 100°C for 1h after crushing, centrifuge at 2000rpm / min for 3min, take the supernatant to obtain a crude sugar solution;

[0036]S12: Add absolute ethanol to the crude sugar solution described in step S11 at a ratio of 1:1, fully shake it and let it stand at 4°C for 12 hours, centrifuge at 4000rpm / min, take the precipitate and repeat step S12 twice, then freeze-dry the precipitate, Pulverize to obtain the peach gum polysaccharide crude extract as 42g;

[0037] S13: Purification, the peach gum polysaccharide crude extract in step S12 is added with water to form a 2mol / mL polysaccharide solution, the fiber column is pretreated, and then deionized water is used to equilibrate the DEAE-52 cellulose column, and the polysaccharide solution is slowly passed through the sample, Finally, it was eluted with 0.2mo...

Embodiment 2

[0044] Preparation of Peach Gum Polysaccharide Extract:

[0045] S11: Wash 50g of raw peach gum to remove impurities, add 500ml of water to soak for 10h, heat the homogenate to 100°C for 2h after crushing, centrifuge at 4000rpm / min for 3min, take the supernatant to obtain a crude sugar solution;

[0046] S12: Add absolute ethanol to the crude sugar solution described in step S11 at twice the amount of the crude sugar solution, shake it fully and let it stand at 0°C for 12 hours, centrifuge at 4000rpm / min, take the precipitate and repeat step S12 for 3 times, then freeze the precipitate Dried and pulverized to obtain the crude extract of peach gum polysaccharide;

[0047] S13: Add water to the peach gum polysaccharide crude extract in step S12 to form a 2.5mol / mL polysaccharide solution, pass through a DEAE-52 cellulose column, elute with 0.5mol / mL NaCl solution, collect the eluted samples, and Filter through a μm microporous membrane, concentrate and dry to obtain 30 g of pea...

Embodiment 3

[0054] Preparation of Peach Gum Polysaccharide Extract:

[0055] S11: Wash 50g of raw peach gum to remove impurities, add 800ml of water to soak for 10h, heat the homogenate to 100°C for 2h after crushing, centrifuge at 4000rpm / min for 3min, take the supernatant to obtain a crude sugar solution;

[0056] S12: Add 5 times the volume of absolute ethanol to the crude sugar solution described in step S11, shake it fully, let it stand at 4°C for 12 hours, centrifuge at 6000rpm / min, take the precipitate and repeat step S12 for 3 times, freeze-dry the precipitate, Pulverize to get peach gum polysaccharide crude extract;

[0057] S13: Add water to the crude peach gum polysaccharide extract in step S12 to form a 5mol / mL polysaccharide solution, pass through a DEAE-52 cellulose column, elute with a 1mol / mL NaCl solution, collect the eluted sample, and filter it in a dialysis bag , concentrated and dried to obtain 37g of peach gum polysaccharide extract.

[0058] Preparation of peach g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com