Lignin epoxy resin/carbon fiber reinforced anti-aging composite material

A technology of plain epoxy resin and carbon fiber materials, which is applied in the field of lignin epoxy resin/carbon fiber reinforced anti-aging composite materials, can solve the problems of increasing the cost of composite materials, application restrictions, time-consuming and laborious, and achieve good support and reinforcement. , excellent mechanical properties, and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

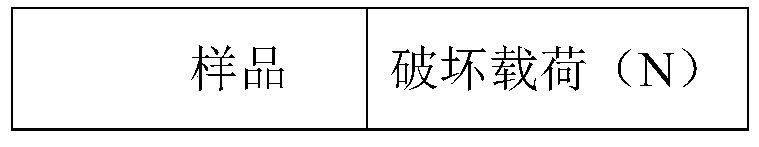

Image

Examples

preparation example 1

[0044] Add 60g ethylene glycol monomethyl ether and 10g deionized water in reaction vessel, be placed in constant temperature water bath under stirring condition, pass into nitrogen, the 100g glycidyl acrylate monomer phase that will contain 0.7gAIBN initiator is slowly added dropwise, in React at 60-80°C for 4-6 hours. After the polymerization is completed, let it stand for cooling and dry in vacuum to obtain a viscous liquid product, polyglycidyl acrylate, which is hereinafter referred to as polymer 1.

preparation example 2

[0046] Change the polymerization monomer into 100g glycidyl methacrylate, and other conditions are the same as in Preparation Example 1 to obtain the product polyglycidyl methacrylate (polymer 2).

preparation example 3

[0048] The polymerized monomer was changed to 110 g of 4-hydroxybutyl acrylate glycidyl ether, and the other conditions were the same as in Preparation Example 1 to obtain the product poly 4-hydroxybutyl acrylate glycidyl ether (polymer 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com