Fertilizer containing natural plant growth substances and preparation process of fertilizer

A technology of natural plant and preparation process, which is applied in the field of fertilizer to achieve the effects of low production cost, increased root vigor, and enhanced drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

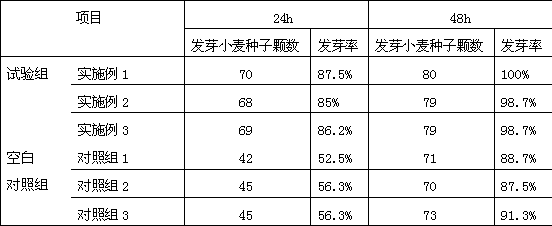

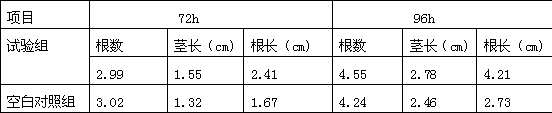

Examples

Embodiment 1

[0034] The technical scheme provided by the present embodiment is as follows: a fertilizer containing natural plant growth substances and a preparation process thereof, comprising the steps of:

[0035] Step 1, raw material processing: cleaning the ginkgo fruit to obtain the cleaned ginkgo fruit;

[0036] Step 2, lactic acid bacteria fermentation: mix the lactic acid bacteria with the cleaned ginkgo fruit in a mass ratio of 1:1000, seal and anaerobically ferment for 20 days;

[0037] Step 3, superfine pulverization: dry the product of step 2 at 70°C, then put it into a jet mill for pulverization, pass through a 20-mesh sieve, and make superfine powder;

[0038] Step 4, compound enzyme enzymatic hydrolysis: add cellulase and pectinase according to 0.2%5% and 0.1%% of the weight of the superfine powder respectively, and add an ethanol solution with a mass fraction of 10 times the weight of the superfine powder and 40% to adjust the pH was 4.2, and 1.5 was enzymatically hydrolyz...

Embodiment 2

[0050] The technical scheme provided by the present embodiment is as follows: a fertilizer containing natural plant growth substances and a preparation process thereof, which is characterized in that it comprises the following steps:

[0051] Step 1, raw material processing: cleaning the ginkgo fruit to obtain the cleaned ginkgo fruit;

[0052] Step 2, lactic acid bacteria fermentation: mix the lactic acid bacteria with the cleaned ginkgo fruit in a mass ratio of 1:5000, seal and anaerobically ferment for 25 days;

[0053] Step 3, superfine pulverization: dry the product of step 2 at 70°C, then put it into a jet mill to pulverize it, pass through a 40-mesh sieve, and make superfine powder;

[0054] Step 4, compound enzyme enzymatic hydrolysis: add cellulase and pectinase according to 0.4% and 0.2% of the weight of the superfine powder respectively, and add 15 times the weight of the superfine powder with a mass fraction of 50% ethanol solution to adjust the pH to 4.4, Enzymol...

Embodiment 3

[0066] The technical scheme provided by the present embodiment is as follows: a fertilizer containing natural plant growth substances and a preparation process thereof, which is characterized in that it comprises the following steps:

[0067] Step 1, raw material processing: cleaning the ginkgo fruit to obtain the cleaned ginkgo fruit;

[0068] Step 2, lactic acid bacteria fermentation: mix the lactic acid bacteria with the cleaned ginkgo fruit in a mass ratio of 1:10000, seal and anaerobically ferment for 30 days;

[0069] Step 3, ultrafine pulverization: dry the product of step 2 at 70°C, then put it into a jet mill for pulverization, pass through a 60-mesh sieve, and make superfine powder;

[0070] Step 4, compound enzyme enzymatic hydrolysis: add cellulase and pectinase according to 0.5% and 0.3% of the weight of the superfine powder respectively, and add an ethanol solution with a mass fraction of 20 times the weight of the superfine powder with a mass fraction of 75%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com