Injectable and rapidly-gelatinized composite hydrogel and preparation method thereof

A composite hydrogel and gelation technology, used in pharmaceutical formulations, pharmaceutical science, drug delivery, etc., can solve problems such as easy shedding, poor degradability of gel dressings, and poor adhesion between hydrogels and wounds. Conducive to industrialization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

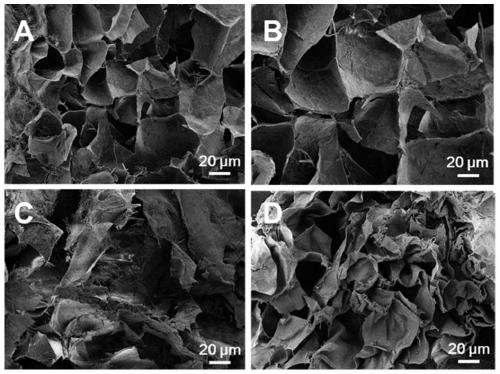

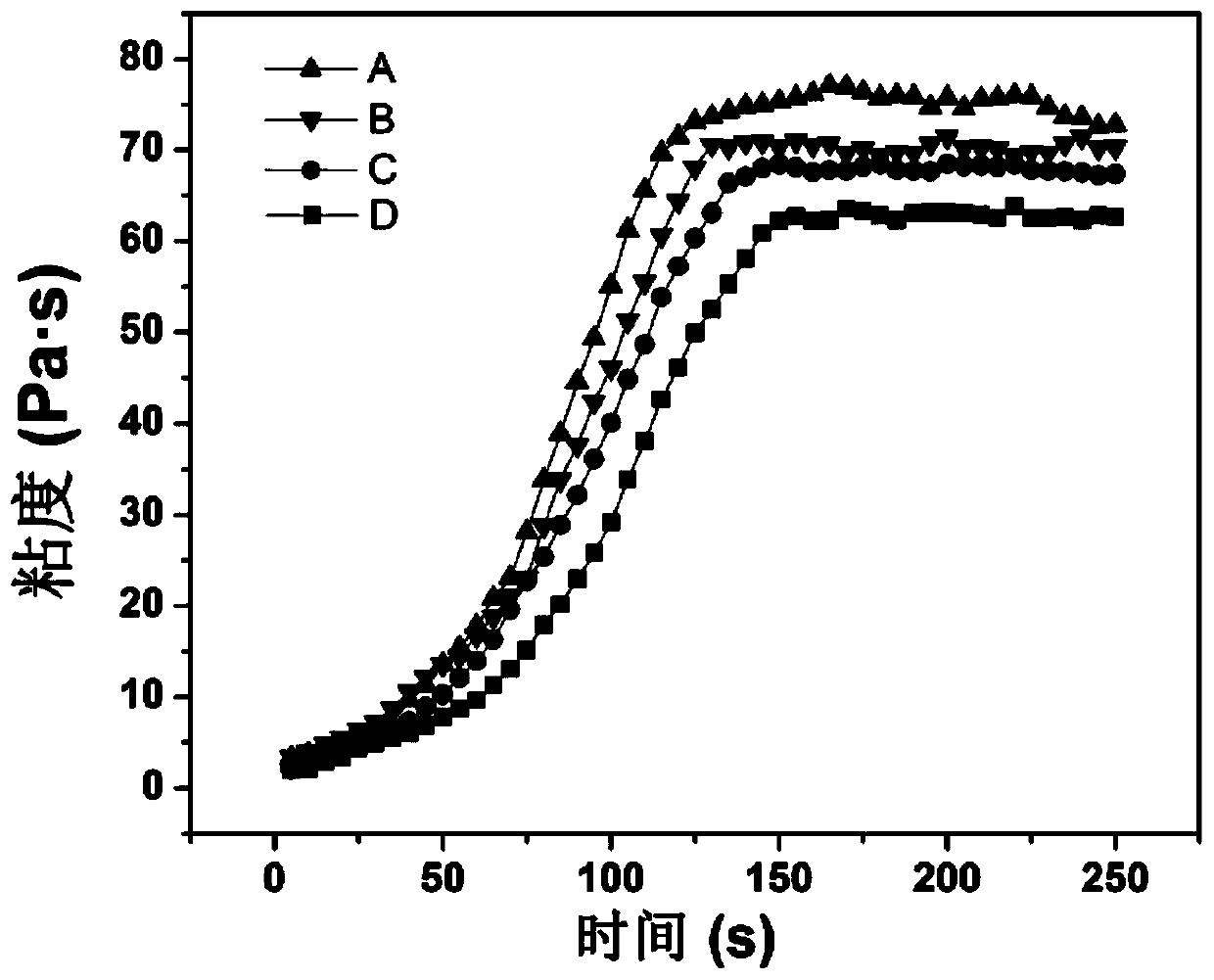

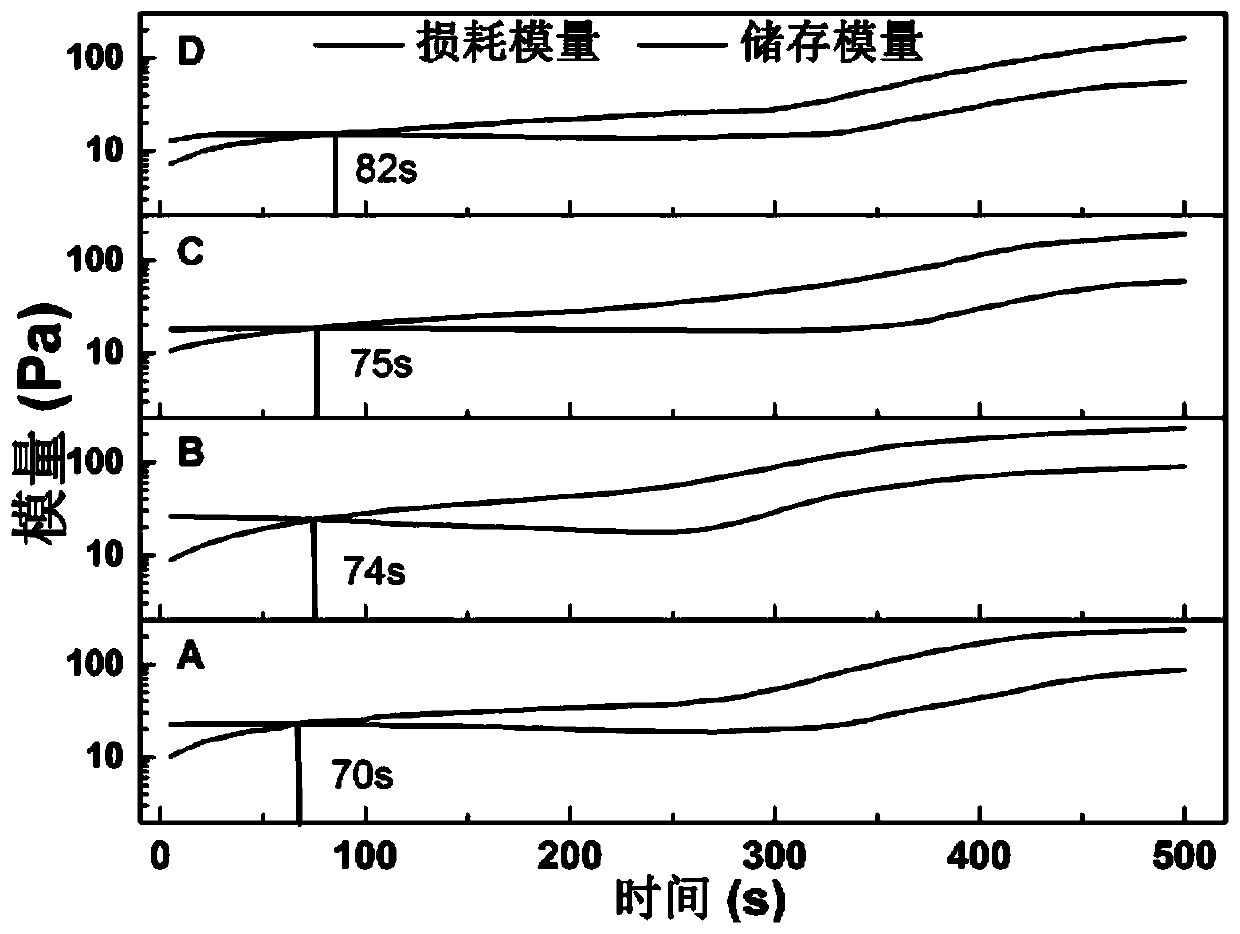

[0030] The composite hydrogel of this example is an injectable and rapidly gelling composite hydrogel based on succinyl chitosan-aldehydated hyaluronate, which combines succinyl chitosan and aldhylated hyaluronic acid Based on the excellent characteristics of sodium nitrite, the carbon-nitrogen double bond is formed through the reaction of amino group and aldehyde group, so that the polymer can be cross-linked to obtain an injectable and rapidly gelling composite hydrogel.

[0031] Specifically, the preparation process of the injectable and fast-gelling composite hydrogel of succinyl chitosan-formylated hyaluronic acid of the present embodiment is as follows:

[0032] (1) Preparation of succinyl chitosan

[0033] Dissolve chitosan in an appropriate amount of acetic acid solution with a mass fraction of 3%, then add acetone solution of succinic anhydride, and react with magnetic stirring at room temperature for 6 to 24 hours. pH to 9~11; among them, n(chitosan) / n(succinic anhy...

Embodiment 2

[0056] The composite hydrogel of this example is an injectable and rapidly gelling composite hydrogel based on octylated chitosan-alginylated sodium alginate, which combines octylated chitosan and alginylated alginate Based on the excellent characteristics of sodium nitrite, the carbon-nitrogen double bond is formed through the reaction of amino group and aldehyde group, so that the polymer can be cross-linked to obtain an injectable and rapidly gelling composite hydrogel.

[0057] Specifically, the preparation process of the injectable and rapidly gelling composite hydrogel of octylated chitosan-alginylated sodium alginate is as follows:

[0058] (1) Preparation of Octylated Chitosan

[0059] A certain amount of chitosan is dissolved in an appropriate amount of 3% acetic acid solution, and after being completely dissolved, a certain amount of ethanol is added to make a homogeneous solution, and a certain amount of octanal is added, wherein, n(chitosan) / n( Octanal) is 2:1, 1:...

Embodiment 3

[0069] The composite hydrogel of this example is an injectable and rapidly gelling composite hydrogel based on succinyl chitosan-alginylated sodium alginate, which combines succinyl chitosan and alginylated sodium alginate The excellent characteristics of the compound hydrogel are formed through the reaction of the amino group and the aldehyde group to form a carbon-nitrogen double bond, so that the polymer can be cross-linked to obtain an injectable and fast-gelling composite hydrogel.

[0070] Specifically, the preparation process of the injectable and fast-gelling composite hydrogel of succinyl chitosan-formylated sodium alginate is as follows:

[0071] (1) Preparation of succinyl chitosan

[0072] It is the same as that of Embodiment 1, and will not be repeated here.

[0073] (2) Preparation of alginylated sodium alginate

[0074] It is the same as the second embodiment, and will not be repeated here.

[0075] (3) Preparation of composite hydrogel

[0076] Dissolving s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com