Nanometer porous fiber membrane with microporous/mesoporous structure and preparation method thereof

A mesoporous structure, nanoporous technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of porous material application limitations, high cost of porous membrane synthesis, unstable pore structure, etc., to achieve permanent pore structure, The effect of high porosity and stable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

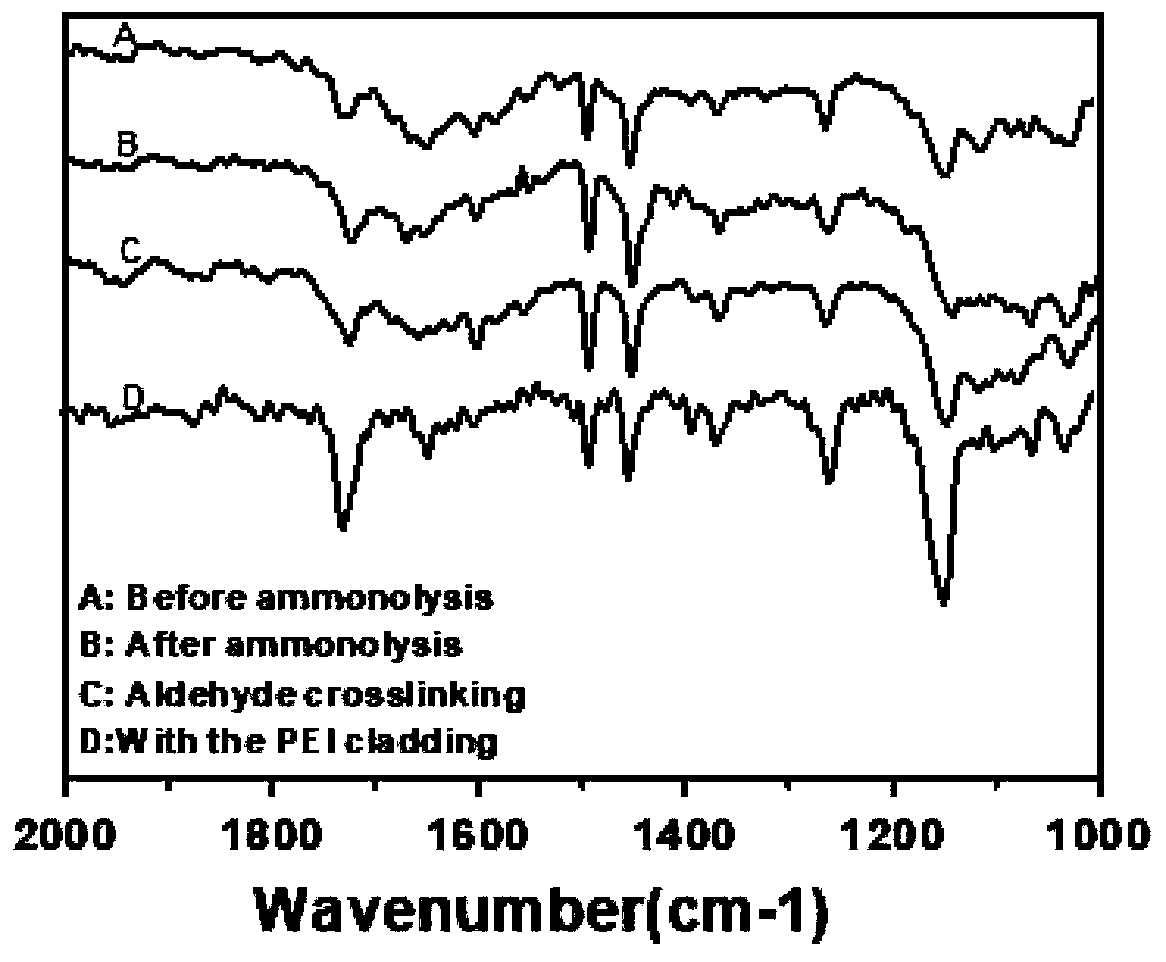

[0049] The preparation method of the nanoporous fiber membrane with microporous / mesoporous structure comprises the following steps:

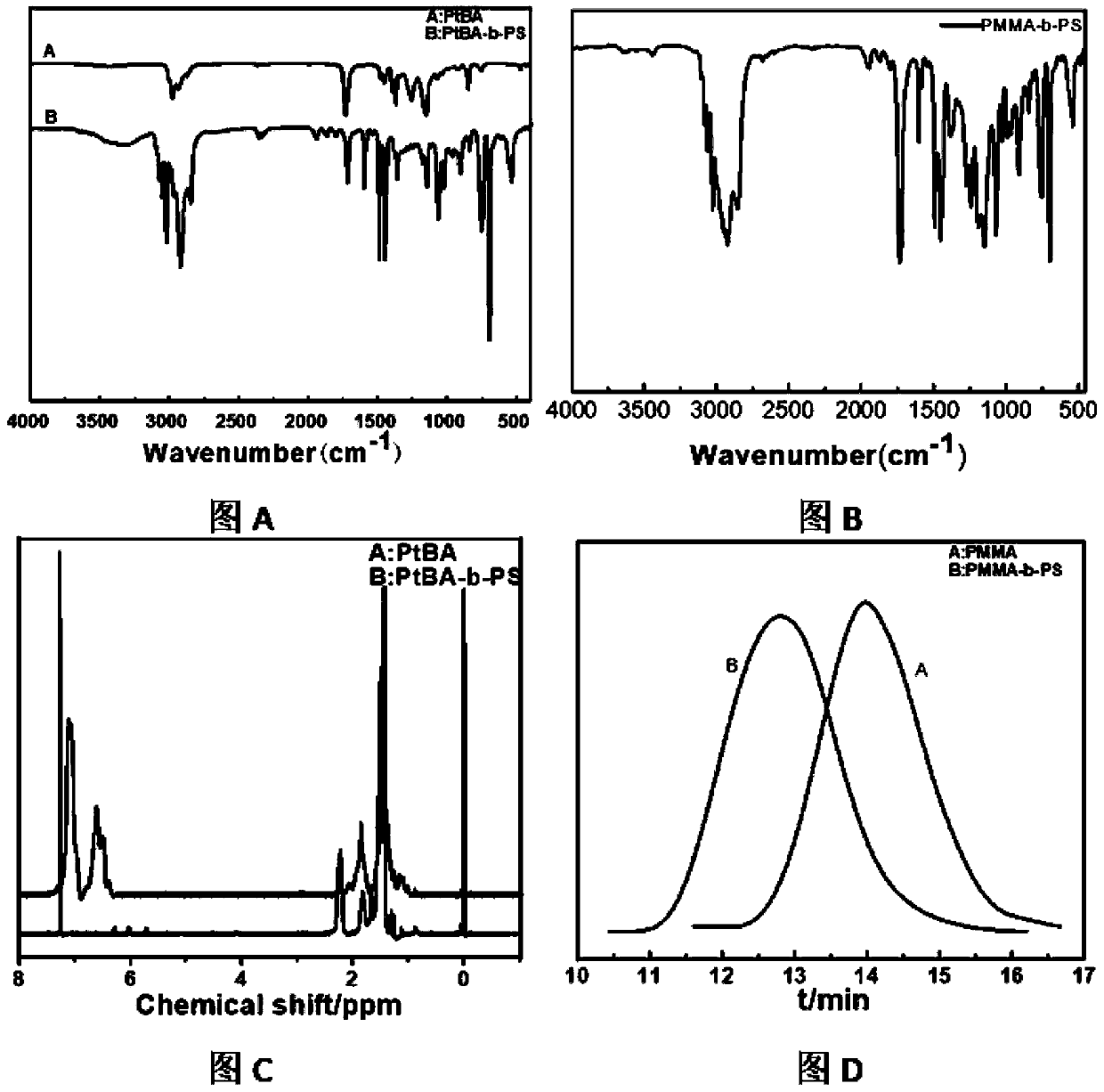

[0050] 1. Preparation of diblock polymer polystyrene (PS)-b-polytert-butyl acrylate (PtBA) spinning polymer raw material

[0051] Add 16.36g of tert-butyl acrylate, 73ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, 59.4mg of cuprous bromide to 30ml of N,N-dimethyl In formamide, mix well, blow nitrogen for a period of time, then add 57ul of ethyl 2-bromoisobutyrate, and react at 80°C for 48h; amide, and re-dissolved in dichloromethane, passed through a column of neutral alumina to remove the catalytic system, and then precipitated the polymer in a mixed medium of methanol / water (1:1, v) by dropwise addition, at 60 ° C Vacuum-dried to constant weight to obtain a white powder, which is a macromolecular initiator;

[0052] Add 37.44g of styrene, 28ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 45mg of cuprous bromide to 30ml of N,N-dimeth...

Embodiment 2

[0071] The difference between Example 2 and Example 1 is: Example 2 changes the feeding of styrene in step 1 of Example 1, adds 24.69g of styrene, and finally obtains a diblock polymer with a molecular weight of 3w-6w. That is, the content of the polystyrene part in the diblock polymer was reduced, so as to explore the influence of the polystyrene part on the properties of the final hypercrosslinked fiber membrane.

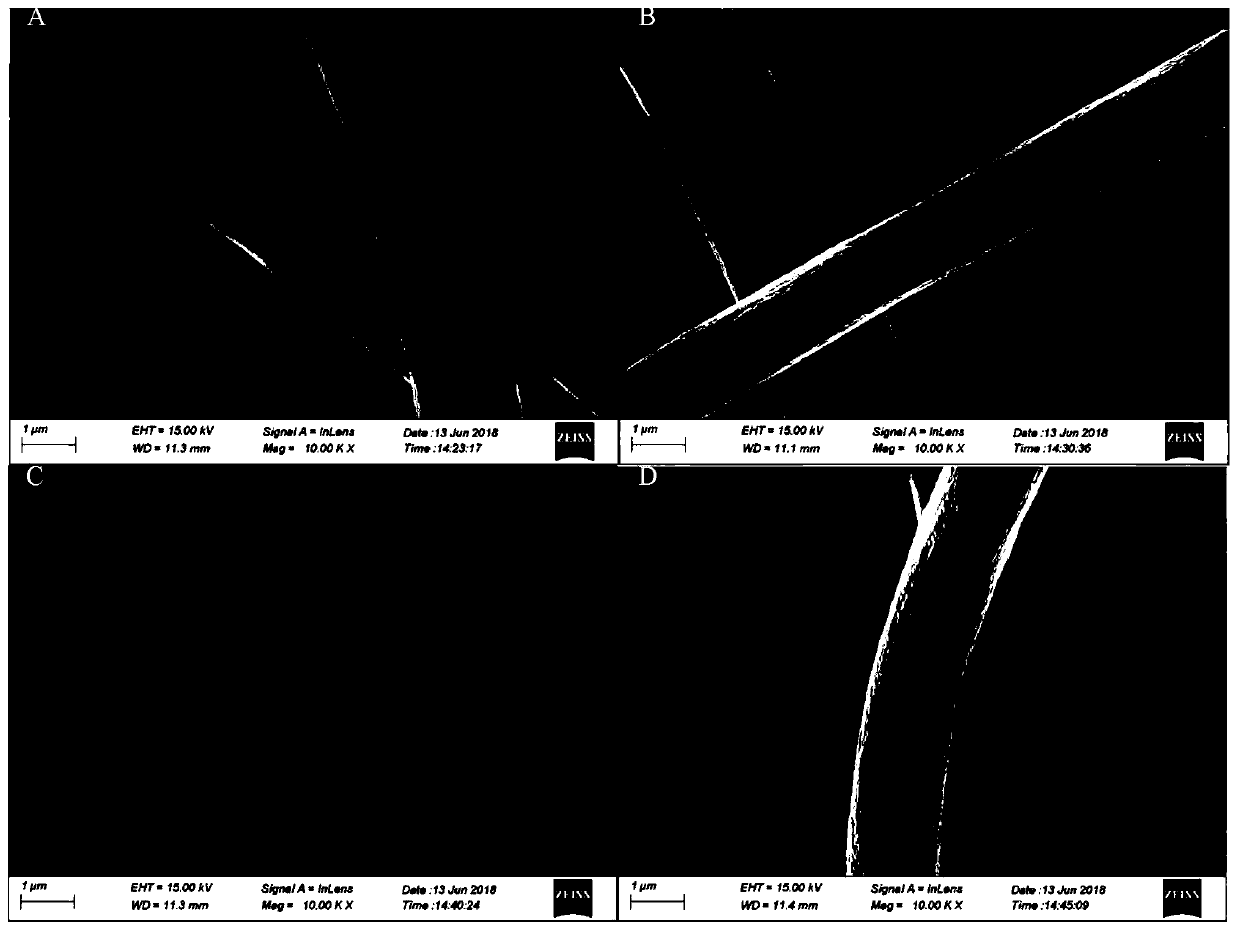

[0072] Figure 9 Shown is the physical picture of the PBA-b-PS hypercrosslinked porous fiber membrane before and after hypercrosslinking. It can be seen that the fiber membrane still has a macroscopic size after hypercrosslinking; changing the content of the PS segment in the diblock can still obtain A well-formed fibrous membrane.

Embodiment 3

[0074] The preparation method of the nanoporous fiber membrane with microporous / mesoporous structure comprises the following steps:

[0075] 1. Preparation of diblock polymer polystyrene (PS)-b-polymethyl methacrylate (PMMA) spinning polymer raw material

[0076] Add 12.78g of methyl methacrylate, 73ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 59.4mg of cuprous bromide to 30ml of N,N-dimethyl In base formamide, mix well, blow nitrogen for a period of time, then add 57ul of ethyl 2-bromoisobutyrate, and react at 80°C for 48h; after the reaction, remove N,N-dimethyl Formamide, and re-dissolved in dichloromethane, passed through a column of neutral alumina to remove the catalytic system, and then precipitated the polymer in a mixed medium of methanol / water (1:1, v) by dropwise addition, at 60°C Dry it under vacuum to constant weight to obtain a white powder, which is the macromolecular initiator;

[0077] Add 37.44g of styrene, 28ul of N,N,N′,N″,N″-pentamethyldiethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com