Multi-element small-amount high-formability magnesium alloy and short-process preparation method thereof

A magnesium alloy, high forming technology, applied in the field of metal materials, can solve the problems of unfavorable green production of enterprises, low solidification cooling rate, high alloying element content, shortening and homogenizing heat treatment, obvious market competitive advantage, and low alloy content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

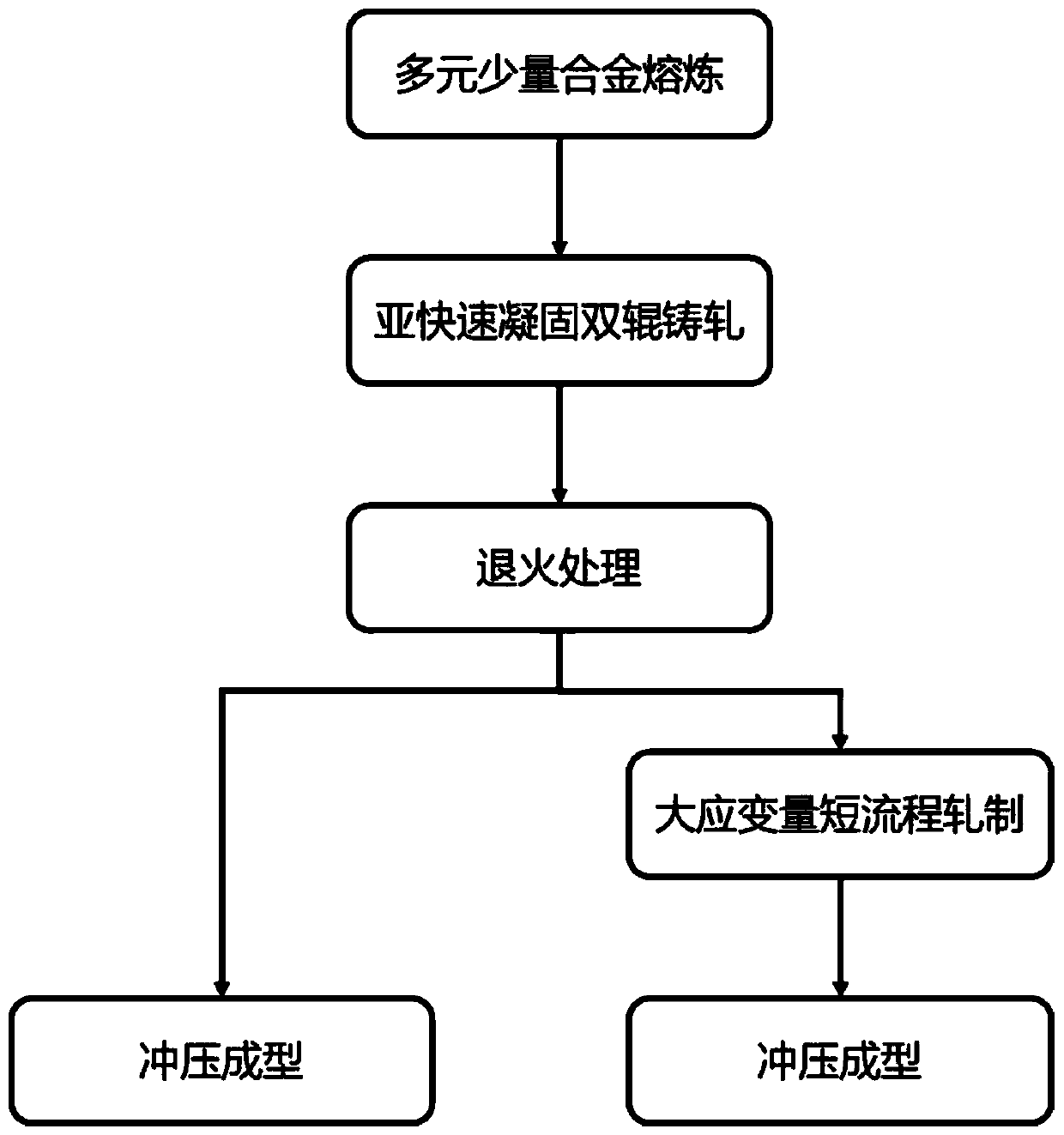

Method used

Image

Examples

Embodiment 1

[0031] Taking the Mg-0.5Zn-0.5Ca-0.3Mn-0.3Sn alloy as an example, the batching is carried out according to the mass percentage, and the specific steps are as follows.

[0032] S1. Multivariate small amount alloy smelting:

[0033] (1) Prepare materials according to the above magnesium alloy composition content, including pure magnesium, pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy.

[0034] (2) The protective gas is continuously introduced into the melting furnace, and the protective gas is SF 6 and CO 2 Preheat the pure magnesium ingot to 473K in the crucible, and then heat up to 973K for melting.

[0035] (3) After the magnesium ingot is melted, slag is removed to remove impurities and oxide layers on the surface of the melt to obtain a pure magnesium melt.

[0036] (4) Add pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy which have been preheated at 373K to the above pure magnesium melt. ...

Embodiment 2

[0044] Taking the Mg-1.0Zn-0.8Ca-0.2Mn-0.1Sn alloy as an example, the batching is carried out according to the mass percentage, and the specific steps are as follows.

[0045] S1. Multivariate small amount alloy smelting:

[0046] (1) Prepare materials according to the above magnesium alloy composition content, including pure magnesium, pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy.

[0047] (2) The protective gas is continuously introduced into the melting furnace, and the protective gas is SF 6 and CO 2 Preheat the pure magnesium ingot to 673K in the crucible, and then heat up to 973K for melting.

[0048] (3) After the magnesium ingot is melted, slag is removed to remove impurities and oxide layers on the surface of the melt to obtain a pure magnesium melt.

[0049] (4) Adding pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy preheated at 423K to the above pure magnesium melt respectively...

Embodiment 3

[0057] Taking the Mg-1.5Zn-0.2Ca-0.2Mn-0.2Sn alloy as an example, the batching is carried out according to the mass percentage, and the specific steps are as follows.

[0058] S1. Multivariate small amount alloy smelting:

[0059] (1) Prepare materials according to the above magnesium alloy composition content, including pure magnesium, pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy.

[0060] (2) The protective gas is continuously introduced into the melting furnace, and the protective gas is SF 6 and CO 2 Preheat the pure magnesium ingot to 473K in the crucible, and then heat up to 953K for melting.

[0061] (3) After the magnesium ingot is melted, slag is removed to remove impurities and oxide layers on the surface of the melt to obtain a pure magnesium melt.

[0062] (4) Add pure zinc, pure tin, magnesium-calcium master alloy and magnesium-manganese master alloy which have been preheated at 373K to the above pure magnesium melt. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com