Catalytic digestion column and its preparation method, cod cr Rapid measurement device and method of using the same

A cylinder and porous ceramic technology, applied in the environmental field, can solve the problems of expensive reagent materials, difficult conditions to control, long analysis cycle, etc., to avoid harm to the operator and the environment, high accuracy, easy to carry and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] a COD Cr The preparation of rapid assay device specifically comprises the following steps:

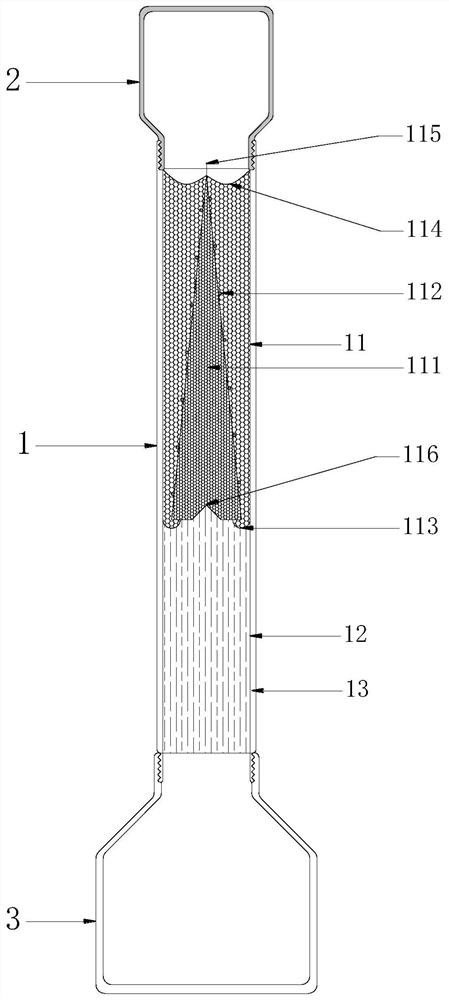

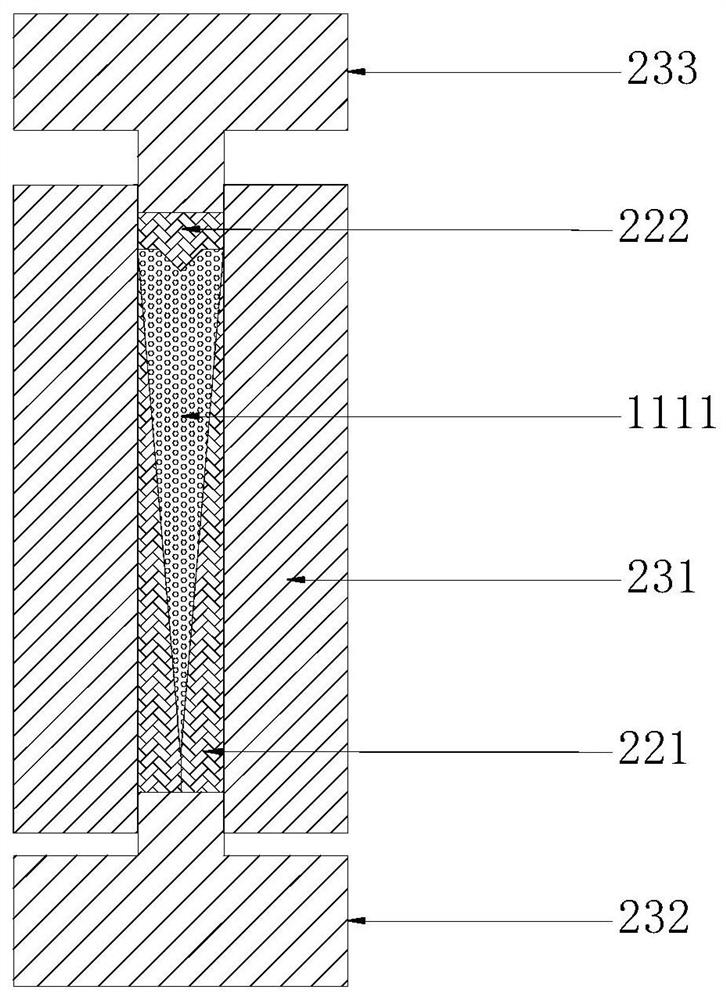

[0121] One, the preparation method of catalytic digestion column 1, its technological process sees Figure 5, including the following steps:

[0122] 1. Immerse 100g of 325-mesh diatomite in 0.5mol / L nitric acid solution containing 10% hydrogen peroxide by mass, heat and keep boiling slightly for 10 minutes, and separate solid and liquid to obtain diatoms after removing impurities and expanding pores earth;

[0123] Wash the diatomite after impurity removal and pore expansion to near neutrality, soak in the aqueous solution of chelating dispersant containing 100g / L urea, 10g / L acetic acid and 50g / L citric acid, ultrasonically vibrate for 20min, and place in a belt In the airtight container with the air release valve, vacuumize the container, the relative vacuum degree is -0.1MPa, keep it for 120min, open the air release valve, let the pressure in the container return to norma...

Embodiment 2

[0160] a COD Cr Preparation of Rapid Assay Device 2

[0161] One, the preparation method of catalytic digestion column 2, with embodiment 1, difference is:

[0162] (1) In step 2, the calcium nitrate tetrahydrate consumption is 9.46g;

[0163] (2) In step 3, the amount of tetra-n-butyl titanate is 13.61g;

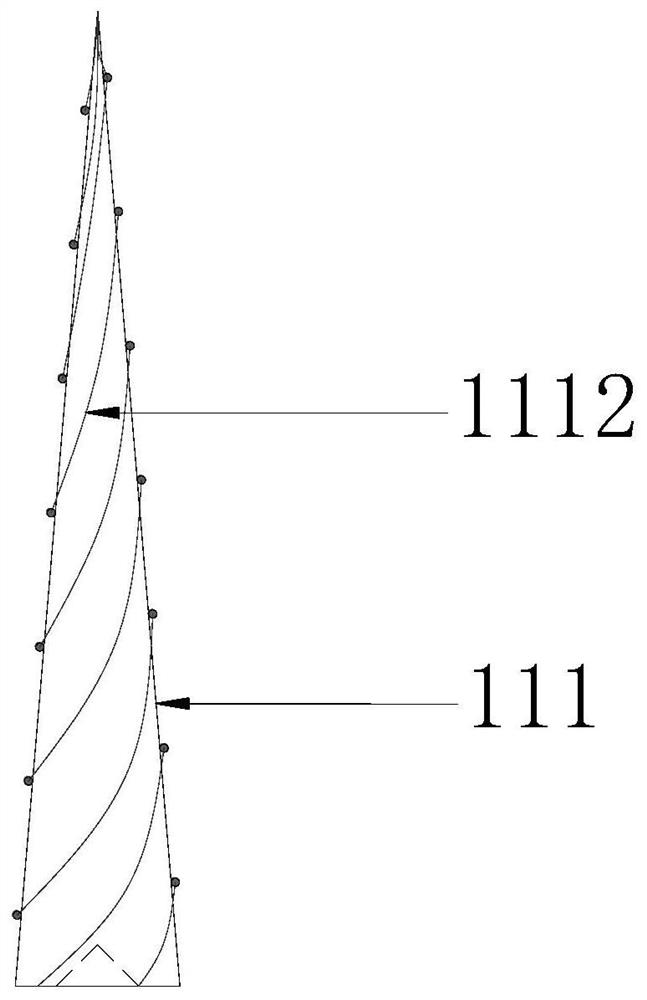

[0164] (3) In step 5, get an appropriate amount of raw powder obtained in step 3, place the cone height 45mm, and the bottom surface diameter is 6mm in the conical mold body;

[0165] (4) In step 7, during the molding process of the column body of the catalytic digestion column, supplement the powder, after pressurization, the height of the column body in the mold is 56.8mm, demoulding, after roasting according to the method of Example 1, the length obtained is 55mm Catalytic digestion column column;

[0166] (5) In step 9, the catalytic digestion column 2 is obtained, and the apparent porosity of the column is 39%;

[0167] (6) In step 10, measure the liquid absorptio...

Embodiment 3

[0184] a COD Cr Preparation of Rapid Assay Device 3

[0185] One, the preparation method of catalytic digestion column 3, with embodiment 1, difference is:

[0186] (1) In step 2, the amount of calcium nitrate tetrahydrate taken is 7.08g;

[0187] (2) In step 3, under vigorous stirring, the amount of tetra-n-butyl titanate to be used is 10.21 g;

[0188] (3) In step 5, the conical mold adopts a cone height of 50mm, and the bottom surface diameter is 8mm;

[0189] (4) In step 6, get 5 cotton threads that adsorb tetra-n-butyl titanate and strontium nitrate obtained in step 4, and the distance between the cotton thread and the upper intersection point of the cone bottom surface circumference is 5mm;

[0190] (5) In step 7, the inner diameter of the mold body of the catalytic digestion column is 11mm, pressurized, and after supplementing the powder, the height of the column body is 62mm, and after calcining according to the method of Example 1, a catalytic digestion column with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com