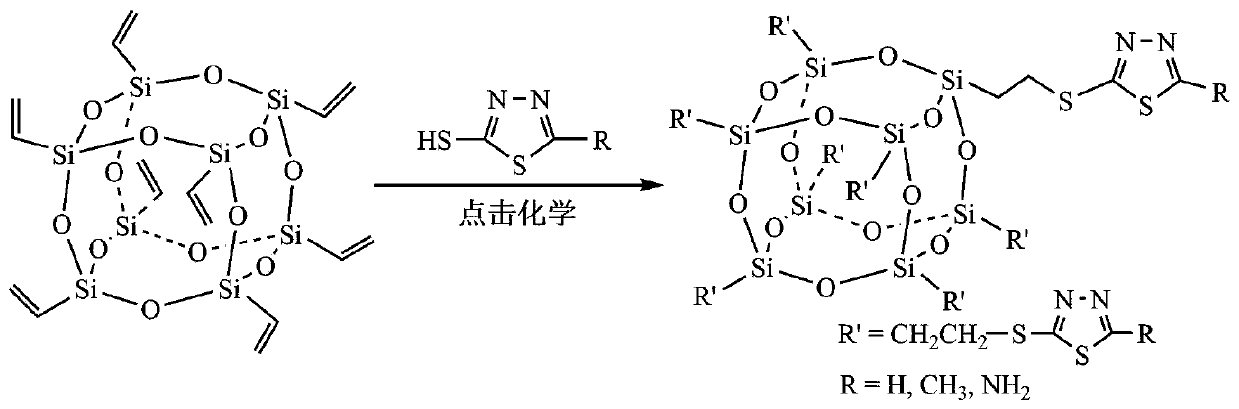

POSS-based adsorbent for heavy metal ions and thiol-ene click chemistry preparation method

A heavy metal ion and adsorbent technology, which is applied in the fields of environmental protection and material science, can solve the problems of low exchange capacity, generally around tens of milligrams per gram, secondary pollution, etc., and achieve simple and efficient process and saturated adsorption capacity High and stable adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

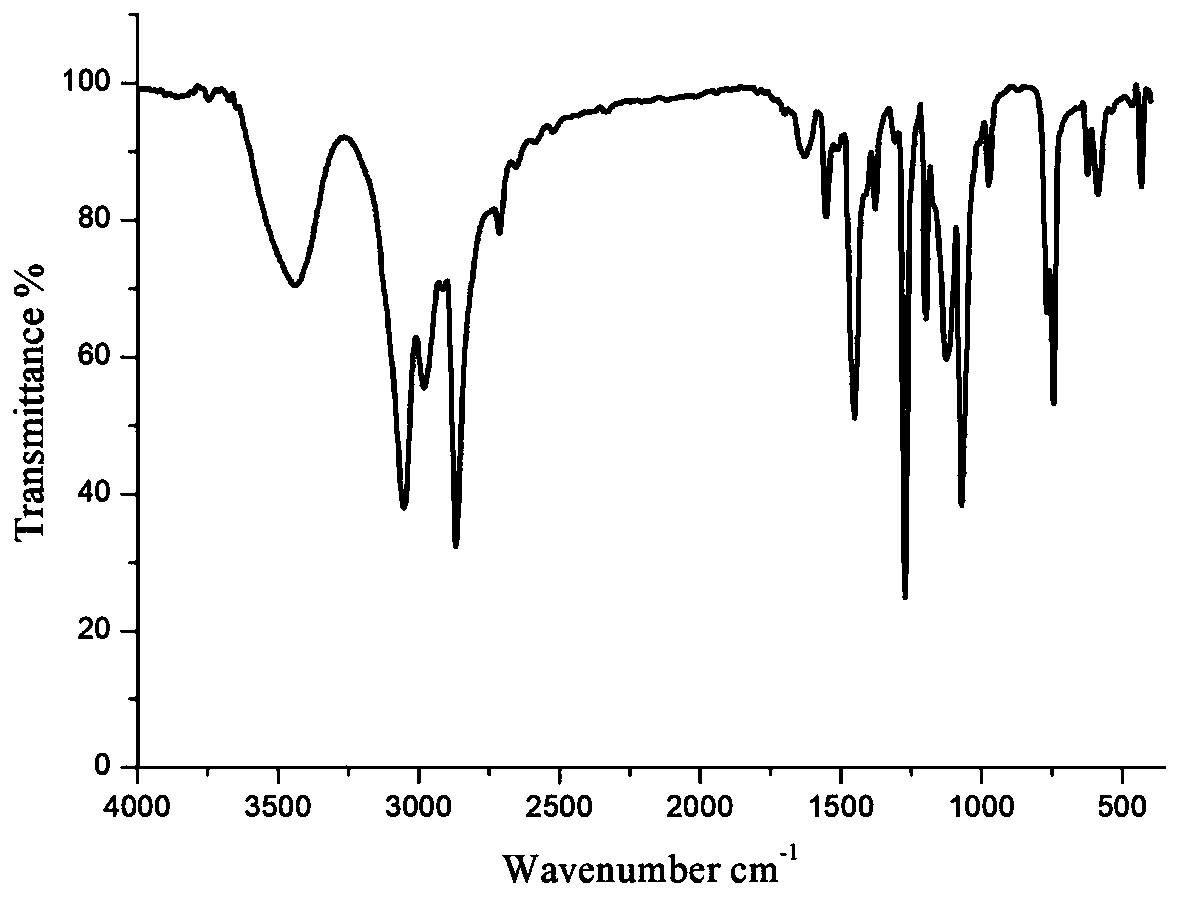

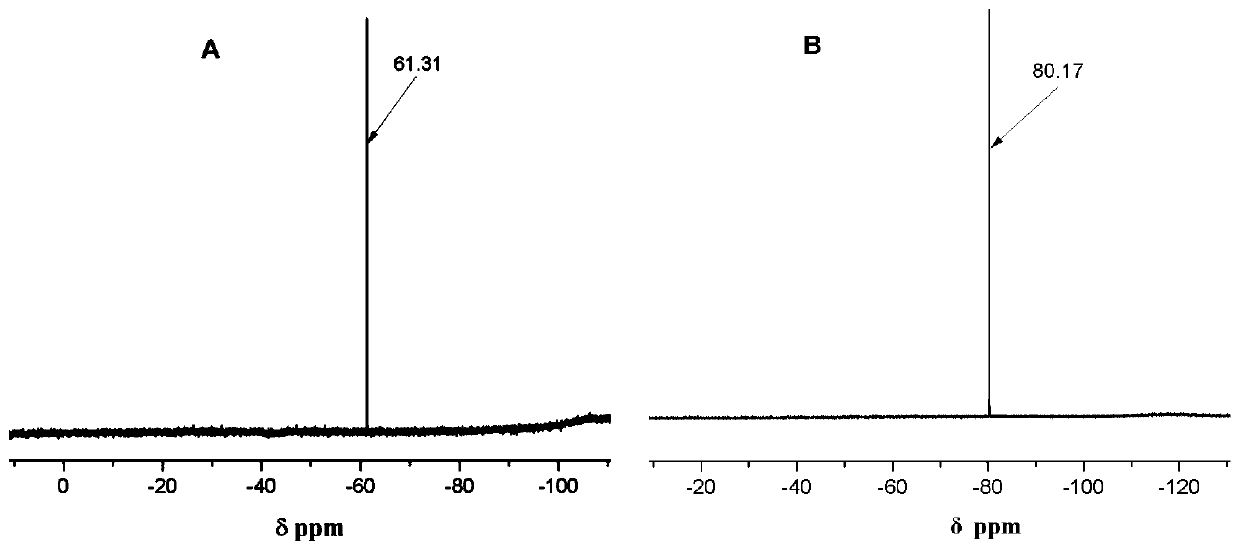

Embodiment 1

[0022] At room temperature, dissolve 2.0g octavinyl POSS in 30mL tetrahydrofuran, then add 3.34g 2-methyl-5-mercapto-1,3,4-thiadiazole and 0.02g 2,2-dimethoxy 2-phenyl acetophenone, put the mixed solution at a wavelength of 365nm and a light intensity of 20mW / cm 2 Under high ultraviolet light, react for 30 minutes under magnetic stirring, and then evaporate and concentrate the mixed solution to obtain a crude product. The crude product was precipitated in methanol, the supernatant was removed by centrifugation, repeated 3 times, and then the precipitate was placed in a drying oven at 60°C and vacuum dried for 12 hours to obtain a POSS-based heavy metal ion adsorbent (4.80g).

Embodiment 2

[0024] At room temperature, dissolve 2.0g octavinyl POSS in 30mL tetrahydrofuran, then add 6.68g 2-methyl-5-mercapto-1,3,4-thiadiazole and 0.02g 2,2-dimethoxy 2-phenyl acetophenone, put the mixed solution at a wavelength of 365nm and a light intensity of 20mW / cm 2 Under high ultraviolet light, react for 30 minutes under magnetic stirring, and then evaporate and concentrate the mixed solution to obtain a crude product. The crude product was precipitated in methanol, the supernatant was removed by centrifugation, repeated 3 times, and then the precipitate was placed in a drying oven at 60°C and vacuum dried for 12 hours to obtain a POSS-based heavy metal ion adsorbent (5.20g)

Embodiment 3

[0026] At room temperature, dissolve 2.0g octavinyl POSS in 30mL tetrahydrofuran, then add 4.2g 2-methyl-5-mercapto-1,3,4-thiadiazole and 0.02g 2,2-dimethoxy 2-phenyl acetophenone, put the mixed solution at a wavelength of 365nm and a light intensity of 20mW / cm 2 Under high ultraviolet light, react for 30 minutes under magnetic stirring, and then evaporate and concentrate the mixed solution to obtain a crude product. Precipitate the crude product in methanol, remove the supernatant by centrifugation, repeat 3 times, then put the precipitate in a drying oven at 60°C and vacuum dry for 12 hours to obtain POSS-based heavy metal ion adsorbent (5.16g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com