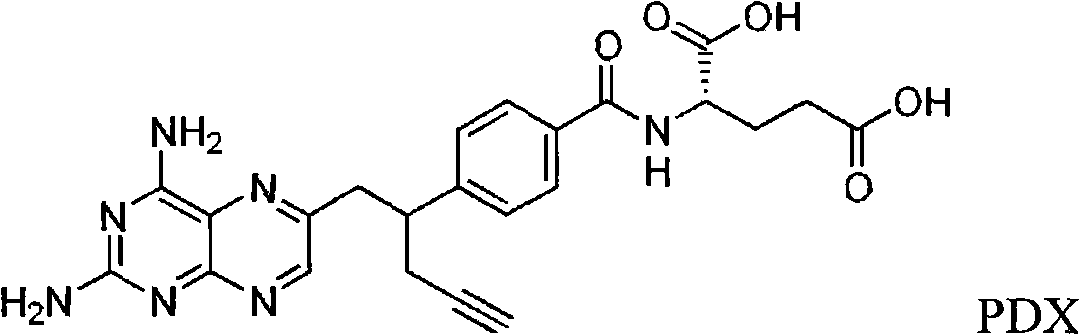

Preparation method of 2-aryl-pentyne-4-olic acid ester compounds

A compound and alkyl technology, applied in the field of preparation of 2-aryl-pent-4-ynoic acid ester compounds, can solve the problems of harsh reaction conditions, unsuitable for large-scale industrial production, and difficult to separate, and achieves easy industrialization production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

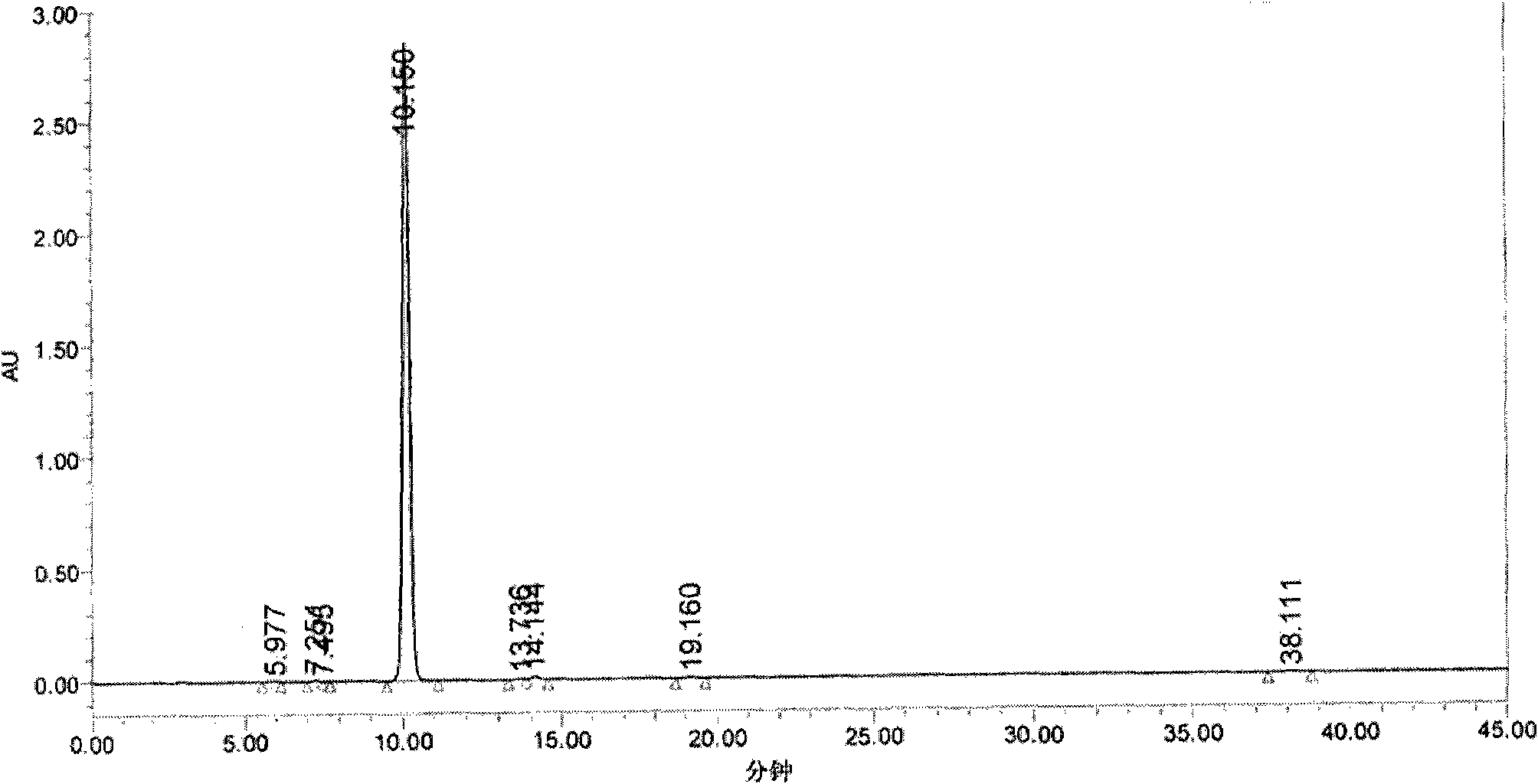

Examples

Embodiment 1

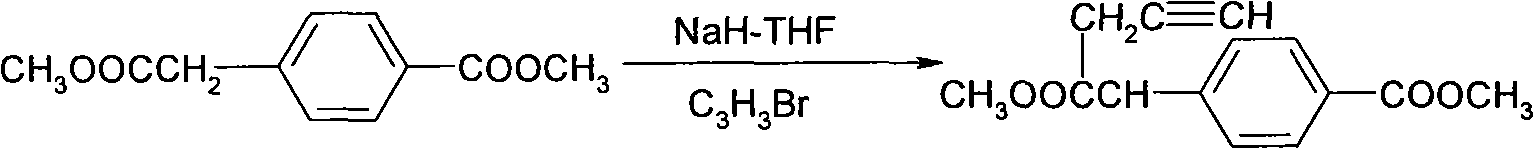

[0050] Preparation of 2-(4-(ethoxycarbonyl)phenyl)-2-(prop-2-ynyl)-malonate (III)

[0051] Dissolve 2-(4-(ethoxycarbonyl)phenyl)-malonic acid diethyl (IV) (12.3g, 40mmol) and 3-bromopropyne (5.72g, 48mmol) in acetone (100mL) Add potassium carbonate (22.1g, 160mmol), heat to reflux, stir for 2 hours, cool to room temperature, add a large amount of water to dilute, adjust pH to 3-4 with 2N dilute hydrochloric acid, extract with ethyl acetate (300mL*3), and combine The organic phase was washed with water, washed with saturated brine, dried over anhydrous magnesium sulfate, filtered, the filtrate was evaporated to dryness, 200-300 mesh silica gel column chromatography (petroleum ether: ethyl acetate = 20:1), and the solvent was evaporated to obtain a yellow oil 物9.7g.

Embodiment 2

[0053] Preparation of 2-(4-(methoxycarbonyl)phenyl)-2-(prop-2-ynyl)-malononitrile (III)

[0054] Dissolve 2-(4-(methoxycarbonyl)phenyl)-malononitrile (IV) (10.0g, 50mmol) and 3-bromopropyne (8.92g, 75mmol) in acetone (120mL), add carbonic acid Potassium (17.3g, 125mmol), heat and stir to reflux, after 2 hours, cool to room temperature, add a large amount of water to dilute, adjust the pH to 3-4 with 2N dilute hydrochloric acid, extract with ethyl acetate (300mL*3), combine the organic phases, Wash with water, saturated brine, dry with anhydrous magnesium sulfate, filter, evaporate the filtrate, 200-300 mesh silica gel column chromatography (petroleum ether: ethyl acetate = 20:1), evaporate the solvent to obtain 8.9 g of yellow solid.

Embodiment 3

[0056] Preparation of 2-[(4-carboxy)phenyl]-pent-4-ynoic acid (II)

[0057] The 2-(4-(ethoxycarbonyl)phenyl)-2-(prop-2-ynyl)-malonic acid diethyl (III) (9.7g, 28.0mmol) obtained in Example 1 was dissolved in In methanol (30mL), add potassium hydroxide (15.8g, 280mmol) aqueous solution (30mL), warm to reflux, stir for 2 hours, cool to room temperature, add water to dilute, evaporate methanol under reduced pressure, ethyl acetate (100mL*3 ) Extract, combine the organic phases, wash with water, wash with saturated brine, dry with anhydrous sodium sulfate, filter, evaporate the filtrate, and recrystallize (petroleum ether: ethyl acetate = 1:1) to obtain 5.8 g of white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com