Streptomycete TJ561, product for preventing and controlling successive cropping obstacle of soil, preparation method and application thereof and application of eugenol

A soil continuous cropping obstacle, TJ561 technology, applied in the field of microorganisms, can solve the problems of low utilization rate of Streptomyces, low rate of Streptomyces fermentation sporulation, etc., to improve soil continuous cropping obstacles, improve vegetable disease resistance, and suppress diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In a preferred embodiment, the preparation method of the spore suspension comprises: Streptomyces TJ561 using the first solid medium, cultured upside down at 27-29°C for 3-5 days, collecting the spores into sterile water to obtain the spore suspension . The first solid medium includes: glucose 6-9g / L, peptone 1.5-3.5g / L, soybean meal powder 1.5-2.1g / L, yeast powder 1-2g / L and agar powder 17-23g / L, pH8.0 -8.5. Streptomyces TJ561 is solidly fermented on this medium, and the spore seed liquid required for fermentation can be obtained quickly and in large quantities, and the spores formed are of good quality.

[0054] Further preferably, the first solid medium includes: glucose 8g / L, peptone 2.5g / L, soybean meal powder 1.8g / L, yeast powder 1.5g / L and agar powder 20g / L, pH 8.0-8.5.

[0055] In a preferred embodiment, the fermentation conditions of Streptomyces TJ561 include: solid fermentation at 26-28° C. for 2-4 days.

[0056] Preferably, the second solid medium for sol...

Embodiment 1

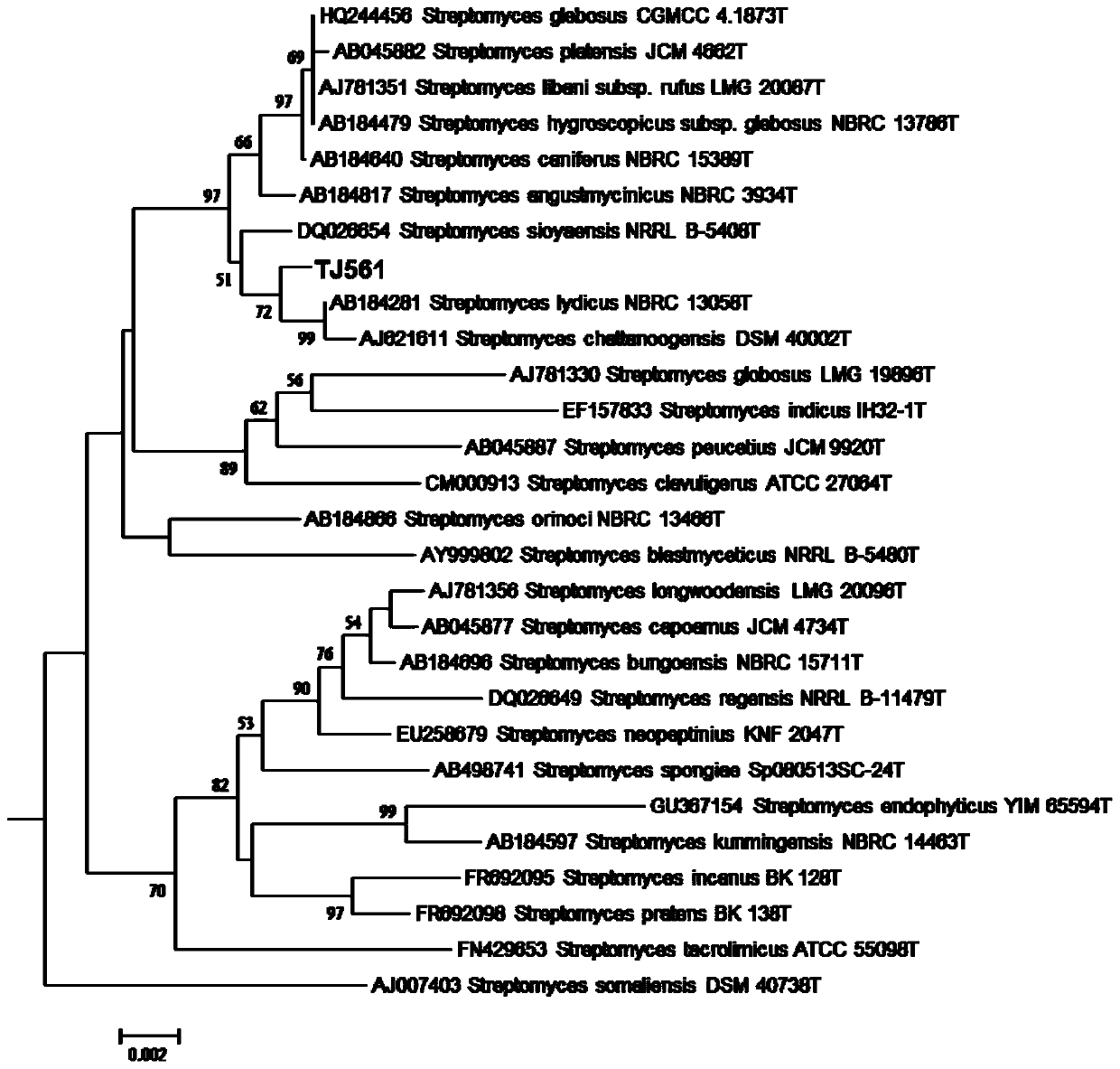

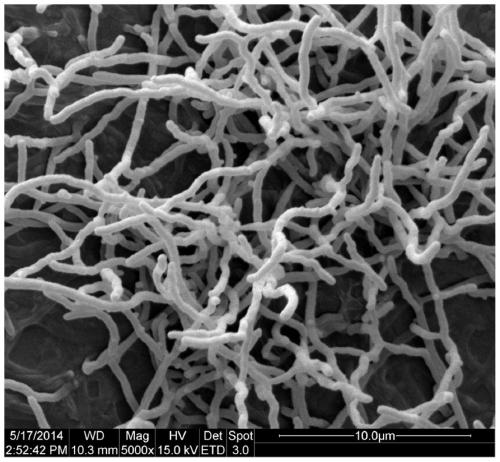

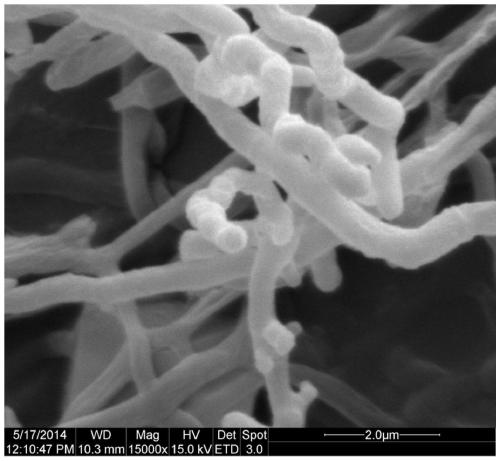

[0061] Screening, identification and preservation of Streptomyces TJ561 of embodiment 1

[0062] (1) The strain TJ561 was isolated from vegetable soil in Baodi District, Tianjin. The collected field soil samples were dried in an oven at 100°C for 24 hours, taken out and cooled to room temperature at room temperature for later use.

[0063] (2) Preparation method of strain solid separation medium: Weigh 5.0g of glucose, 6.0g of starch, 5.0g of malt extract, 3.0g of yeast powder, 2.0g of peptone, 3.0g of ammonium sulfate, and 0.2g of calcium carbonate, and add 1.0L Fully dissolve the water, adjust the pH between 7.5-8.0 with 0.1M sodium hydroxide, then add 20g of agar powder, mix evenly, divide into 500ml triangular flasks according to the liquid volume of 200ml per bottle, and store at 121°C Sterilize under high temperature for 30 minutes, and when the culture is cooled to 50-60°C at room temperature, add 1.0ml of sterile nystatin aqueous solution with a concentration of 1000m...

Embodiment 2

[0069] The bacteriostasis of embodiment 2 Streptomyces TJ561

[0070] Indoor antimicrobial spectrum test of strain TJ561.

[0071] (1) Fermentation broth preparation: using the block-digging inoculation method, inoculate the mature strain TJ561 grown on a solid slant medium into a mixture containing glucose 15g / L, peptone 6g / L, yeast powder 4g / L, and calcium carbonate 0.2g / L , in a liquid medium with pH=7.5-8.0. Cultivate for 96 hours at 28°C with a rotational speed of 180 rpm. Centrifuge at 3000 rpm for 5 min, and take the supernatant for later use.

[0072] (2) The strain TJ561 has good antibacterial effect against various plant pathogenic fungi indoors. In the aseptic operation bench, use the inoculation loop to scrape the hyphae of the plant pathogenic fungi Botrytis cinerea, cabbage black spot, bean sclerotia, and Phytophthora capsici growing in the inclined test tube until it is filled with 20ml of sterile water and 20-25 Particle diameter is in the 50ml Erlenmeyer f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com