Preparation method of 2,6-pyridinedicarboxylic acid

A technology of dipicolinic acid and hydrochloric acid, applied in the field of medicinal chemistry, can solve the problems of unsuitability for green industrial production, low yield and selectivity, inconvenient source of raw materials, etc., and achieves low cost, high yield and selectivity, and intermediate Product stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

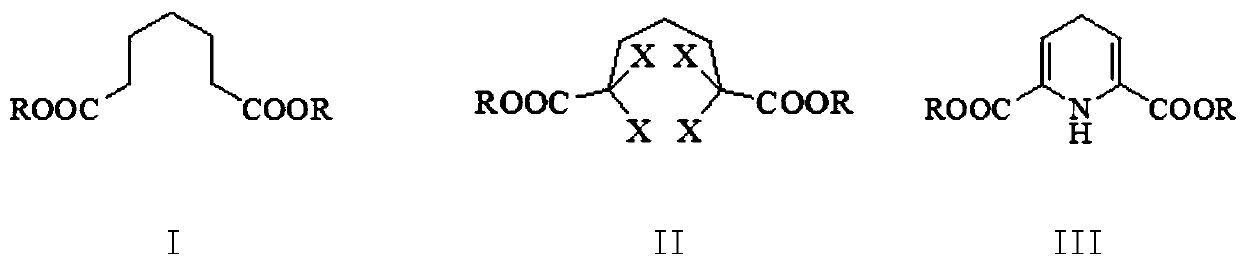

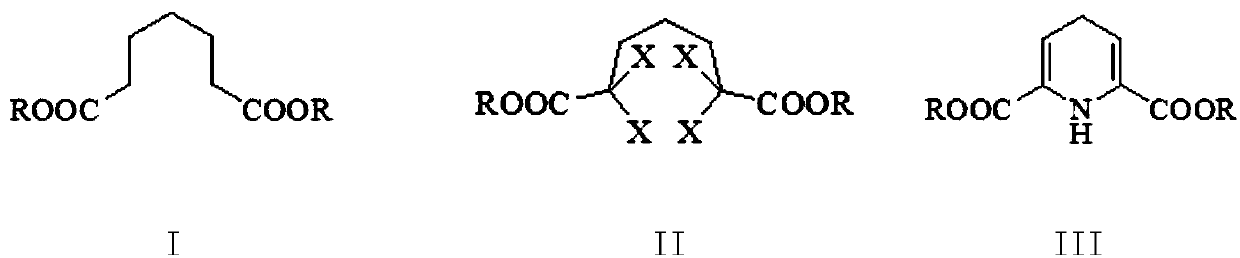

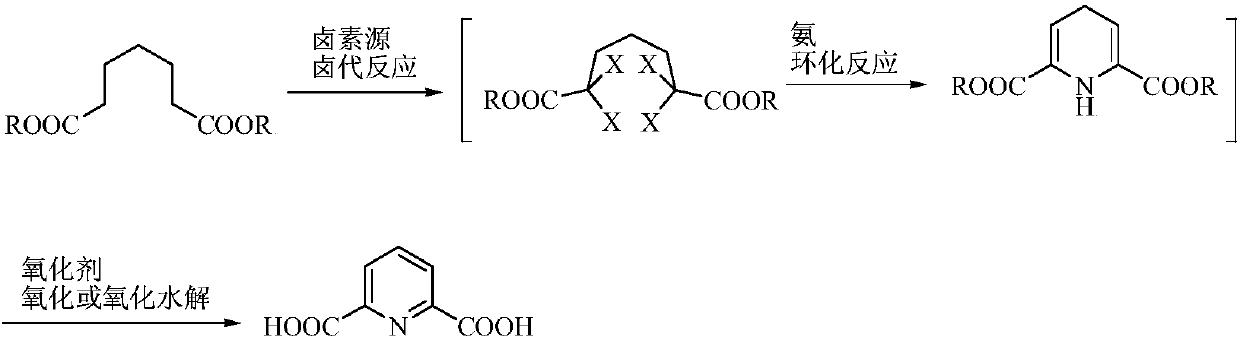

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of 2,6-pyridinedicarboxylic acid

[0044] Add 50 g of acetonitrile, 16.0 g (0.1 mole) of 1,7-pimelic acid, and 0.5 g of aluminum trichloride into a 500 ml four-neck flask connected with stirring, a thermometer, and a reflux condenser. 30 grams of chlorine gas, stirred and reacted at 50-55°C for 8 hours, cooled to 20-25°C, blown off with nitrogen for 2 hours, added 65 grams of 17wt% ammonia water, stirred and reacted at 70-75°C for 5 hours, then cooled to 20-25°C , add 30 grams of 30wt% nitric acid, stir and react at 40-45°C for 4 hours, add the reaction liquid to 200 grams of water, adjust the pH of the system to 2.5-2.0 with hydrochloric acid, filter and dry to obtain 15.0 grams of white solid 2,6-pyridine Dicarboxylic acid, liquid phase purity 99.3%, product yield 89.8%.

[0045] The NMR data of the product are as follows:

[0046] 1 HNMR (DMSO-d6, 400MHz, δ, ppm):

[0047] 8.52 (dd, 1H), 8.77 (d, 2H), 11.0 (s, 2H).

Embodiment 2

[0048] Embodiment 2: Preparation of 2,6-pyridinedicarboxylic acid

[0049]Add 100 g of chloroform, 18.8 g (0.1 mole) of dimethyl 1,7-pimelate, 0.5 g of aluminum trichloride, and feed chlorine , a total of 30 grams of chlorine gas was introduced, stirred and reacted at 30-35°C for 8 hours, cooled to 20-25°C, blown off with nitrogen for 2 hours, added 60 grams of 17wt% ammonia methanol solution, stirred and reacted at 50-55°C for 8 hours, then cooled to 20-25°C, add 20 grams of 30wt% hydrogen peroxide, stir and react at 30-35°C for 4 hours, add 45 grams of 20wt% sodium hydroxide aqueous solution, stir and react at 30-35°C for 4 hours, separate layers, and wash the organic phase with water for two Second-rate. 20 grams of water each time, combine the water phases, adjust the pH value of the water phase to 2.5-2.0 with hydrochloric acid, filter, and dry to obtain 15.3 grams of white solid 2,6-pyridinedicarboxylic acid, the liquid phase purity is 99.2%, and the product yield is 91...

Embodiment 3

[0050] Embodiment 3: Preparation of 2,6-pyridinedicarboxylic acid

[0051] In a 500 ml four-necked flask connected with stirring, a thermometer, a reflux condenser and a constant pressure dropping funnel, add 100 g of chloroform, 18.8 g (0.1 mole) of dimethyl 1,7-pimelate, 0.6 g of 40 wt% Hydrobromic acid, add dropwise a mixed liquid of 72.0 grams of bromine and 50 grams of chloroform at 30-35°C, stir and react at 30-35°C for 7 hours after dropping, cool to 20-25°C, blow off with nitrogen for 2 hours, add 60 gram of 17wt% ammonia water, stirred and reacted at 60-65°C for 6 hours, then cooled to 20-25°C, added 20 grams of 30wt% hydrogen peroxide, stirred and reacted at 30-35°C for 4 hours, then added 45 grams of 20wt% sodium hydroxide aqueous solution, Stir the reaction at 30-35°C for 4 hours, separate the layers, and wash the organic phase twice with water. 20 grams of water each time, combine the water phases, adjust the pH value of the water phase to 2.5-2.0 with hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com